- 08

- Feb

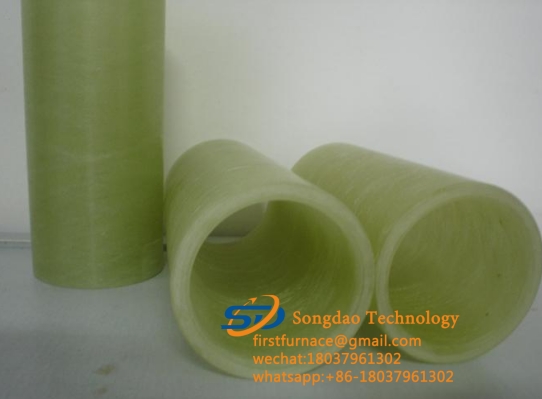

Theknoloji ea Tlhahiso le Nts’etsopele le Tšebeliso ea Fiberglass Tube

Theknoloji ea Tlhahiso le Nts’etsopele le Tšebeliso ea Fiberglass Tube

Hona le mefuta e meraro ea sehlooho ea khalase ea fiber tube production processes: reciprocating filament winding process, continuous filament winding process and centrifugal casting process.

Ts’ebetso e ts’oanelang ea “filament winding” (ea mokhoa o tsitsitseng oa bolelele bo tsitsitseng): Ts’ebetsong ena, tanka ea ho qoelisa e khutlela morao ka mandrel e potolohang, ‘me likhoele tse telele tsa khalase li behoa ka lehlakoreng le itseng la oblique le amanang le mandrel axis, le angle e thusang. (ke hore. The angle winding) e laoloa ke karo-karolelano ea lebelo le tsamaeang la tanka ea ho qoela ho lebelo la ho potoloha ha mandrel, ‘me motsamao oa phetolelo oa tanka ea ho qoela o laoloa ke taolo ea electromechanical computerized. Palo ea mekhahlelo e tsoelipanang e ntse e eketseha butle-butle ho fihlela botenya ba lerako bo entsoeng bo fihla. Ka mor’a hore ho phethiloe ho phethoa, resin e hlahang sehloohong e phekoloa haholo. Ka mor’a ho phekola, mandrel e tlosoa phala ea fiberglass.

Continuous filament winding process (belonging to continuous method): The process is that the tube passes through a feeding station that supplies resin pre-impregnated roving, chopped glass fiber reinforced plastic fiber and resin sand mixture in motion, and the tube is continuously advancing in the core mold. made in.

Centrifugal casting process (belonging to the fixed-length method): In this process, the cut glass fiber reinforced material and sand are fed into a steel mold fixed on the bearing, and the unsaturated resin with catalyst is injected into one end of the steel mold to make the steel mold. It impregnates the reinforcing material. Under the action of centrifugal force, the resin replaces the air in the fibers and fillers, thereby producing a dense composite material without pores. Due to the action of centrifugal force, the inner wall of the tube forms a smooth and clean resin-rich inner surface layer. Cures at higher temperatures. The pipe made by this method is also called glass fiber reinforced plastic sand pipe.