- 08

- Feb

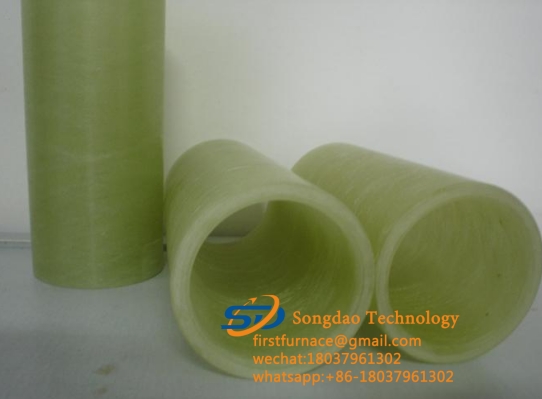

Téknologi Produksi sareng Pangembangan sareng Aplikasi Tabung Fiberglass

Téknologi Produksi sareng Pangembangan sareng Aplikasi Tabung Fiberglass

Aya tilu jinis utami tabung serat kaca production processes: reciprocating filament winding process, continuous filament winding process and centrifugal casting process.

Prosés pungkal filamén Reciprocating (milik metode panjang tetep): Dina prosés ieu, tank dipping reciprocates jeung mandrel puteran, sarta filaments kaca serat panjang disimpen dina sudut serong tangtu relatif ka sumbu mandrel, sarta sudut bantu. (ie. Sudut pungkal) dikawasa ku babandingan laju pindah tina tank dipping kana speed rotational of mandrel nu, sarta gerakan translasi tina tank dipping ieu dikawasa ku kontrol electromechanical komputerisasi. Jumlah lapisan pungkal laun-laun ngaronjat nepi ka ketebalan témbok dirancang ngahontal. Sanggeus pungkal réngsé, résin dina artikel ieu substansi cageur. Saatos curing, mandrel dipiceun tina pipa orat.

Continuous filament winding process (belonging to continuous method): The process is that the tube passes through a feeding station that supplies resin pre-impregnated roving, chopped glass fiber reinforced plastic fiber and resin sand mixture in motion, and the tube is continuously advancing in the core mold. made in.

Centrifugal casting process (belonging to the fixed-length method): In this process, the cut glass fiber reinforced material and sand are fed into a steel mold fixed on the bearing, and the unsaturated resin with catalyst is injected into one end of the steel mold to make the steel mold. It impregnates the reinforcing material. Under the action of centrifugal force, the resin replaces the air in the fibers and fillers, thereby producing a dense composite material without pores. Due to the action of centrifugal force, the inner wall of the tube forms a smooth and clean resin-rich inner surface layer. Cures at higher temperatures. The pipe made by this method is also called glass fiber reinforced plastic sand pipe.