- 08

- Feb

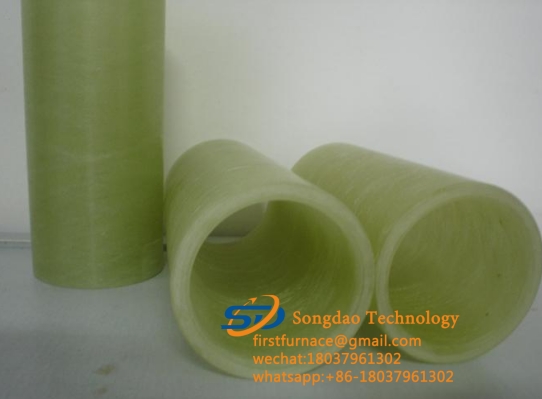

የማምረቻ ቴክኖሎጂ እና ልማት እና የፋይበርግላስ ቱቦ አተገባበር

የማምረቻ ቴክኖሎጂ እና ልማት እና የፋይበርግላስ ቱቦ አተገባበር

ሶስት ዋና ዋና ዓይነቶች አሉ የመስታወት ፋይበር ቱቦ production processes: reciprocating filament winding process, continuous filament winding process and centrifugal casting process.

ተዘዋዋሪ ክር ጠመዝማዛ ሂደት (ቋሚ-ርዝመት ዘዴ ንብረት): በዚህ ሂደት ውስጥ, መጥመቂያው ታንክ የሚሽከረከር mandrel ጋር reprocates, እና ረጅም ፋይበር መስታወት ክሮች mandrel ዘንግ, እና ረዳት አንግል ጋር በተያያዘ የተወሰነ ገደድ ማዕዘን ላይ ይመደባሉ. (ማለትም ጠመዝማዛ አንግል) የዳፕ ታንከሩን የመንቀሳቀሻ ፍጥነት እና የመንደሩ ተዘዋዋሪ ፍጥነት ሬሾን ይቆጣጠራል, እና የዲፕስ ታንክ የትርጉም እንቅስቃሴ በኮምፒዩተር ኤሌክትሮሜካኒካል ቁጥጥር ይቆጣጠራል. የተነደፈው ግድግዳ ውፍረት እስኪደርስ ድረስ የጠመዝማዛ ንብርብሮች ቁጥር ቀስ በቀስ ይጨምራል. ጠመዝማዛው ከተጠናቀቀ በኋላ በጽሁፉ ውስጥ ያለው ሙጫ በደንብ ይድናል. ከታከመ በኋላ, ሜንዶው ከፋይበርግላስ ቱቦ ውስጥ ይወገዳል.

Continuous filament winding process (belonging to continuous method): The process is that the tube passes through a feeding station that supplies resin pre-impregnated roving, chopped glass fiber reinforced plastic fiber and resin sand mixture in motion, and the tube is continuously advancing in the core mold. made in.

Centrifugal casting process (belonging to the fixed-length method): In this process, the cut glass fiber reinforced material and sand are fed into a steel mold fixed on the bearing, and the unsaturated resin with catalyst is injected into one end of the steel mold to make the steel mold. It impregnates the reinforcing material. Under the action of centrifugal force, the resin replaces the air in the fibers and fillers, thereby producing a dense composite material without pores. Due to the action of centrifugal force, the inner wall of the tube forms a smooth and clean resin-rich inner surface layer. Cures at higher temperatures. The pipe made by this method is also called glass fiber reinforced plastic sand pipe.