- 08

- Feb

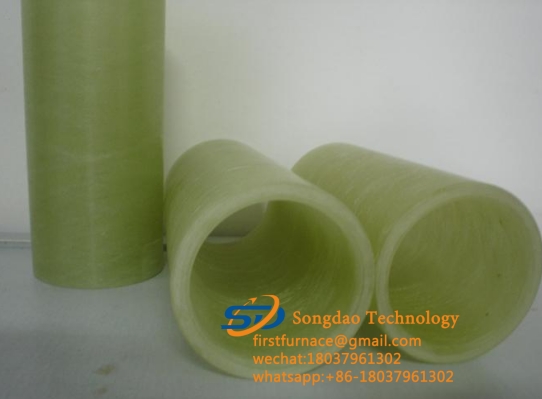

Production Technology and Development and Application of Fiberglass Tube

Production Technology and Development and Application of Fiberglass Tube

There are three main types of glass fiber tube production processes: reciprocating filament winding process, continuous filament winding process and centrifugal casting process.

Reciprocating filament winding process (belonging to the fixed-length method): In this process, the dipping tank reciprocates with the rotating mandrel, and the long fiber glass filaments are placed at a certain oblique angle relative to the mandrel axis, and the auxiliary angle (ie. The winding angle) is controlled by the ratio of the moving speed of the dipping tank to the rotational speed of the mandrel, and the translational movement of the dipping tank is controlled by computerized electromechanical control. The number of winding layers is gradually increased until the designed wall thickness is reached. After the winding is completed, the resin in the article is substantially cured. After curing, the mandrel is removed from the fiberglass pipe.

Continuous filament winding process (belonging to continuous method): The process is that the tube passes through a feeding station that supplies resin pre-impregnated roving, chopped glass fiber reinforced plastic fiber and resin sand mixture in motion, and the tube is continuously advancing in the core mold. made in.

Centrifugal casting process (belonging to the fixed-length method): In this process, the cut glass fiber reinforced material and sand are fed into a steel mold fixed on the bearing, and the unsaturated resin with catalyst is injected into one end of the steel mold to make the steel mold. It impregnates the reinforcing material. Under the action of centrifugal force, the resin replaces the air in the fibers and fillers, thereby producing a dense composite material without pores. Due to the action of centrifugal force, the inner wall of the tube forms a smooth and clean resin-rich inner surface layer. Cures at higher temperatures. The pipe made by this method is also called glass fiber reinforced plastic sand pipe.