- 08

- Feb

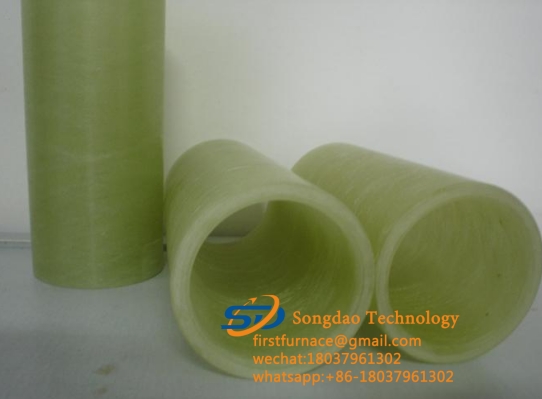

Teknolojia ya Uzalishaji na Maendeleo na Utumiaji wa Fiberglass Tube

Teknolojia ya Uzalishaji na Maendeleo na Utumiaji wa Fiberglass Tube

Kuna aina kuu tatu za kioo fiber tube production processes: reciprocating filament winding process, continuous filament winding process and centrifugal casting process.

Mchakato wa kurudisha nyuma wa vilima vya filamenti (ya njia ya urefu uliowekwa): Katika mchakato huu, tanki ya kuzamisha inalingana na mandrel inayozunguka, na nyuzi za glasi ndefu huwekwa kwenye pembe fulani ya oblique inayohusiana na mhimili wa mandrel, na pembe ya msaidizi. (yaani. Pembe ya vilima) inadhibitiwa na uwiano wa kasi ya kusonga ya tank ya kuzamisha kwa kasi ya mzunguko wa mandrel, na harakati ya kutafsiri ya tank ya kuzamisha inadhibitiwa na udhibiti wa umeme wa kompyuta. Idadi ya tabaka za vilima huongezeka kwa hatua hadi unene wa ukuta uliopangwa ufikiwe. Baada ya kukamilika kwa vilima, resin katika kifungu huponywa kwa kiasi kikubwa. Baada ya kuponya, mandrel huondolewa kwenye bomba la fiberglass.

Continuous filament winding process (belonging to continuous method): The process is that the tube passes through a feeding station that supplies resin pre-impregnated roving, chopped glass fiber reinforced plastic fiber and resin sand mixture in motion, and the tube is continuously advancing in the core mold. made in.

Centrifugal casting process (belonging to the fixed-length method): In this process, the cut glass fiber reinforced material and sand are fed into a steel mold fixed on the bearing, and the unsaturated resin with catalyst is injected into one end of the steel mold to make the steel mold. It impregnates the reinforcing material. Under the action of centrifugal force, the resin replaces the air in the fibers and fillers, thereby producing a dense composite material without pores. Due to the action of centrifugal force, the inner wall of the tube forms a smooth and clean resin-rich inner surface layer. Cures at higher temperatures. The pipe made by this method is also called glass fiber reinforced plastic sand pipe.