- 08

- Feb

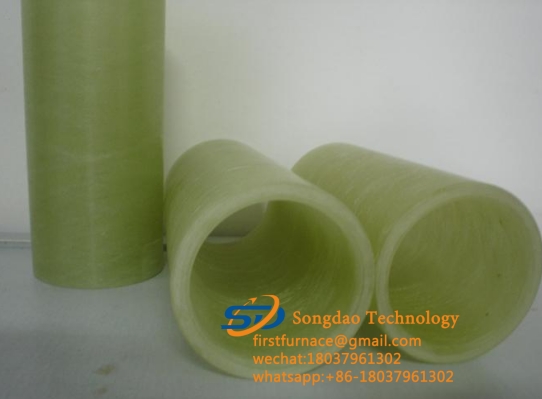

Ubuchwephesha boMveliso kunye noPhuhliso kunye nokuSetyenziswa kweTube yeFiberglass

Ubuchwephesha boMveliso kunye noPhuhliso kunye nokuSetyenziswa kweTube yeFiberglass

Zintathu iintlobo eziphambili ze ityhubhu yeglasi yefiber production processes: reciprocating filament winding process, continuous filament winding process and centrifugal casting process.

Ukubuyisela inkqubo yokujija i-filament (yeyendlela yobude obumiselweyo): Kule nkqubo, itanki yokudipha iphinda ibuyele kwi-mandrel ejikelezayo, kwaye i-filaments yeglasi ye-fiber ende ibekwe kwi-engile e-oblique ehambelana ne-axis ye-mandrel, kunye ne-angle encedisayo. (okt. I-angle ejikelezayo) ilawulwa ngumlinganiselo wesantya esihambayo setanki yokudipha ukuya kwisantya esijikelezayo se-mandrel, kunye nentshukumo yokuguqulela itanki yokudipha ilawulwa ngolawulo lwe-electromechanical lwekhompyutha. Inani leengqimba ezijikelezayo zongezwa ngokuthe ngcembe de kufike ubungakanani bodonga oluyiliweyo. Emva kokuba ukugqiba ukujija kugqityiwe, i-resin kwinqaku iphiliswa kakhulu. Emva kokunyanga, i-mandrel iyasuswa kumbhobho we-fiberglass.

Continuous filament winding process (belonging to continuous method): The process is that the tube passes through a feeding station that supplies resin pre-impregnated roving, chopped glass fiber reinforced plastic fiber and resin sand mixture in motion, and the tube is continuously advancing in the core mold. made in.

Centrifugal casting process (belonging to the fixed-length method): In this process, the cut glass fiber reinforced material and sand are fed into a steel mold fixed on the bearing, and the unsaturated resin with catalyst is injected into one end of the steel mold to make the steel mold. It impregnates the reinforcing material. Under the action of centrifugal force, the resin replaces the air in the fibers and fillers, thereby producing a dense composite material without pores. Due to the action of centrifugal force, the inner wall of the tube forms a smooth and clean resin-rich inner surface layer. Cures at higher temperatures. The pipe made by this method is also called glass fiber reinforced plastic sand pipe.