- 08

- Feb

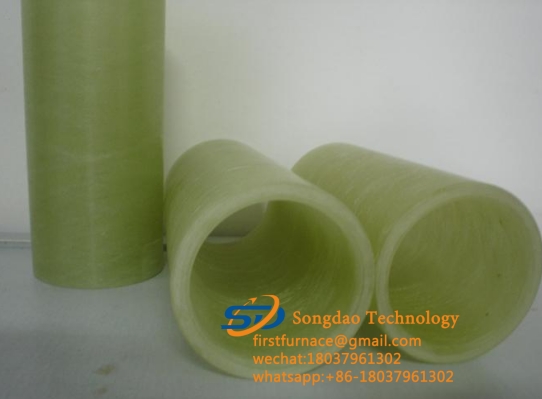

Tehnologija proizvodnje i razvoj i primjena cijevi od fiberglasa

Tehnologija proizvodnje i razvoj i primjena cijevi od fiberglasa

Postoje tri glavne vrste cijev od staklenih vlakana production processes: reciprocating filament winding process, continuous filament winding process and centrifugal casting process.

Proces namotavanja klipnih filamenta (koji pripada metodi fiksne dužine): U ovom procesu, rezervoar za potapanje kruži rotirajućim trnom, a dugačka filamenta od staklenih vlakana postavljaju se pod određenim kosim uglom u odnosu na osovinu trna i pomoćni ugao (tj. Ugao namotaja) kontroliše se odnosom brzine kretanja rezervoara za potapanje i brzine rotacije trna, a translaciono kretanje rezervoara za potapanje kontroliše se kompjuterizovanom elektromehaničkom kontrolom. Broj slojeva namotaja se postepeno povećava dok se ne postigne projektovana debljina zida. Nakon što je namotavanje završeno, smola u artiklu je značajno očvrsnuta. Nakon stvrdnjavanja, trn se uklanja iz cijevi od fiberglasa.

Continuous filament winding process (belonging to continuous method): The process is that the tube passes through a feeding station that supplies resin pre-impregnated roving, chopped glass fiber reinforced plastic fiber and resin sand mixture in motion, and the tube is continuously advancing in the core mold. made in.

Centrifugal casting process (belonging to the fixed-length method): In this process, the cut glass fiber reinforced material and sand are fed into a steel mold fixed on the bearing, and the unsaturated resin with catalyst is injected into one end of the steel mold to make the steel mold. It impregnates the reinforcing material. Under the action of centrifugal force, the resin replaces the air in the fibers and fillers, thereby producing a dense composite material without pores. Due to the action of centrifugal force, the inner wall of the tube forms a smooth and clean resin-rich inner surface layer. Cures at higher temperatures. The pipe made by this method is also called glass fiber reinforced plastic sand pipe.