- 08

- Feb

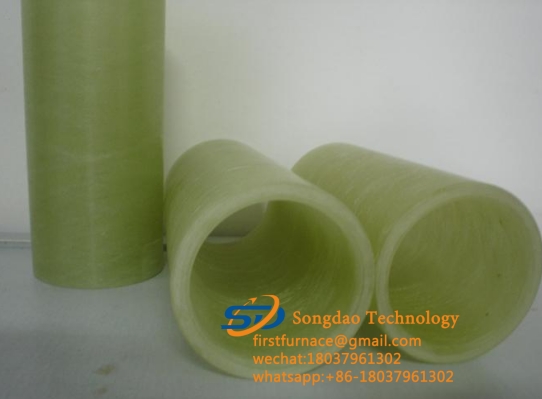

Teknolohiya ng Produksyon at Pag-unlad at Paglalapat ng Fiberglass Tube

Teknolohiya ng Produksyon at Pag-unlad at Paglalapat ng Fiberglass Tube

Mayroong tatlong pangunahing uri ng glass fiber tube production processes: reciprocating filament winding process, continuous filament winding process and centrifugal casting process.

Reciprocating filament winding process (na kabilang sa fixed-length method): Sa prosesong ito, ang dipping tank ay gumaganti sa umiikot na mandrel, at ang mahabang fiber glass filament ay inilalagay sa isang tiyak na pahilig na anggulo na may kaugnayan sa mandrel axis, at ang auxiliary angle (ibig sabihin. Ang winding angle) ay kinokontrol ng ratio ng bilis ng paggalaw ng dipping tank sa rotational speed ng mandrel, at ang translational movement ng dipping tank ay kinokontrol ng computerized electromechanical control. Ang bilang ng mga paikot-ikot na layer ay unti-unting nadaragdagan hanggang sa maabot ang dinisenyo na kapal ng pader. Matapos makumpleto ang paikot-ikot, ang dagta sa artikulo ay lubos na gumaling. Pagkatapos ng paggamot, ang mandrel ay tinanggal mula sa fiberglass pipe.

Continuous filament winding process (belonging to continuous method): The process is that the tube passes through a feeding station that supplies resin pre-impregnated roving, chopped glass fiber reinforced plastic fiber and resin sand mixture in motion, and the tube is continuously advancing in the core mold. made in.

Centrifugal casting process (belonging to the fixed-length method): In this process, the cut glass fiber reinforced material and sand are fed into a steel mold fixed on the bearing, and the unsaturated resin with catalyst is injected into one end of the steel mold to make the steel mold. It impregnates the reinforcing material. Under the action of centrifugal force, the resin replaces the air in the fibers and fillers, thereby producing a dense composite material without pores. Due to the action of centrifugal force, the inner wall of the tube forms a smooth and clean resin-rich inner surface layer. Cures at higher temperatures. The pipe made by this method is also called glass fiber reinforced plastic sand pipe.