- 08

- Feb

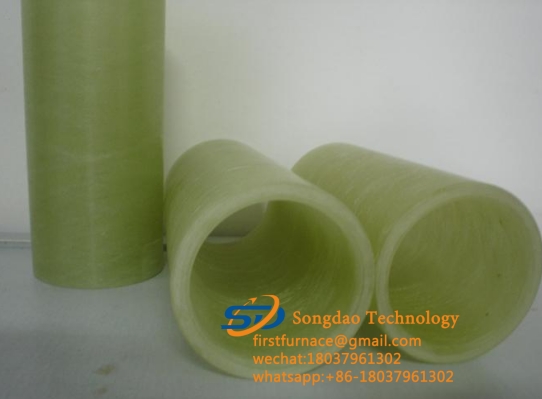

Ishlab chiqarish texnologiyasi va shisha tolali naychani ishlab chiqish va qo’llash

Ishlab chiqarish texnologiyasi va shisha tolali naychani ishlab chiqish va qo’llash

Uch asosiy turi mavjud shisha tolali quvur production processes: reciprocating filament winding process, continuous filament winding process and centrifugal casting process.

Pistonli filamentni o’rash jarayoni (qattiq uzunlikdagi usulga tegishli): Bu jarayonda cho’milish tanki aylanadigan mandrel bilan o’zaro harakatlanadi va uzun tolali shisha filamentlar mandrel o’qiga nisbatan ma’lum bir qiyshiq burchak ostida va yordamchi burchakka joylashtiriladi. (ya’ni o’rash burchagi) cho’milish tankining harakatlanish tezligining mandrelning aylanish tezligiga nisbati bilan nazorat qilinadi va cho’milish tankining translatsiya harakati kompyuterlashtirilgan elektromexanik nazorat bilan boshqariladi. O’ralgan qatlamlar soni mo’ljallangan devor qalinligiga erishilgunga qadar asta-sekin oshiriladi. O’rash tugagandan so’ng, maqoladagi qatronlar sezilarli darajada davolanadi. Qattiqlashgandan so’ng, mandrel shisha tolali quvurdan chiqariladi.

Continuous filament winding process (belonging to continuous method): The process is that the tube passes through a feeding station that supplies resin pre-impregnated roving, chopped glass fiber reinforced plastic fiber and resin sand mixture in motion, and the tube is continuously advancing in the core mold. made in.

Centrifugal casting process (belonging to the fixed-length method): In this process, the cut glass fiber reinforced material and sand are fed into a steel mold fixed on the bearing, and the unsaturated resin with catalyst is injected into one end of the steel mold to make the steel mold. It impregnates the reinforcing material. Under the action of centrifugal force, the resin replaces the air in the fibers and fillers, thereby producing a dense composite material without pores. Due to the action of centrifugal force, the inner wall of the tube forms a smooth and clean resin-rich inner surface layer. Cures at higher temperatures. The pipe made by this method is also called glass fiber reinforced plastic sand pipe.