- 08

- Feb

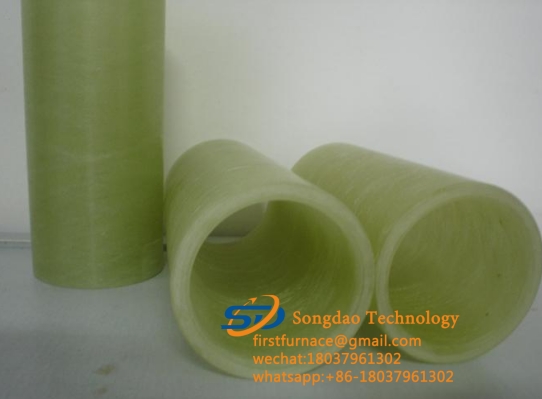

ເຕັກໂນໂລຊີການຜະລິດແລະການພັດທະນາແລະການນໍາໃຊ້ທໍ່ Fiberglass

ເຕັກໂນໂລຊີການຜະລິດແລະການພັດທະນາແລະການນໍາໃຊ້ທໍ່ Fiberglass

ມັນມີສາມປະເພດຕົ້ນຕໍຂອງ ທໍ່ເສັ້ນໃຍແກ້ວ production processes: reciprocating filament winding process, continuous filament winding process and centrifugal casting process.

ຂະບວນການ winding filament reciprocating (ເປັນຂອງວິທີການທີ່ມີຄວາມຍາວຄົງທີ່): ໃນຂະບວນການນີ້, ຖັງ dipping reciprocates ກັບ mandrel ພືດຫມູນວຽນ, ແລະ filaments ເສັ້ນໄຍແກ້ວຍາວຖືກຈັດໃສ່ໃນມຸມສະຫຼຽງທີ່ແນ່ນອນທຽບກັບແກນ mandrel, ແລະມຸມຊ່ວຍ. (ie. ມຸມ winding) ຖືກຄວບຄຸມໂດຍອັດຕາສ່ວນຂອງຄວາມໄວການເຄື່ອນຍ້າຍຂອງຖັງ dipping ກັບຄວາມໄວການຫມຸນຂອງ mandrel, ແລະການແປການເຄື່ອນໄຫວຂອງຖັງ dipping ແມ່ນຄວບຄຸມໂດຍການຄວບຄຸມໄຟຟ້າຄອມພິວເຕີ. ຈໍານວນຂອງຊັ້ນ winding ແມ່ນຄ່ອຍໆເພີ່ມຂຶ້ນຈົນກ່ວາຄວາມຫນາຂອງກໍາແພງອອກແບບໄດ້ບັນລຸໄດ້. ຫຼັງຈາກ winding ແມ່ນສໍາເລັດ, ຢາງໃນບົດຄວາມແມ່ນໄດ້ຮັບການຮັກສາຢ່າງຫຼວງຫຼາຍ. ຫຼັງຈາກການປິ່ນປົວ, mandrel ໄດ້ຖືກໂຍກຍ້າຍອອກຈາກທໍ່ fiberglass.

Continuous filament winding process (belonging to continuous method): The process is that the tube passes through a feeding station that supplies resin pre-impregnated roving, chopped glass fiber reinforced plastic fiber and resin sand mixture in motion, and the tube is continuously advancing in the core mold. made in.

Centrifugal casting process (belonging to the fixed-length method): In this process, the cut glass fiber reinforced material and sand are fed into a steel mold fixed on the bearing, and the unsaturated resin with catalyst is injected into one end of the steel mold to make the steel mold. It impregnates the reinforcing material. Under the action of centrifugal force, the resin replaces the air in the fibers and fillers, thereby producing a dense composite material without pores. Due to the action of centrifugal force, the inner wall of the tube forms a smooth and clean resin-rich inner surface layer. Cures at higher temperatures. The pipe made by this method is also called glass fiber reinforced plastic sand pipe.