- 08

- Feb

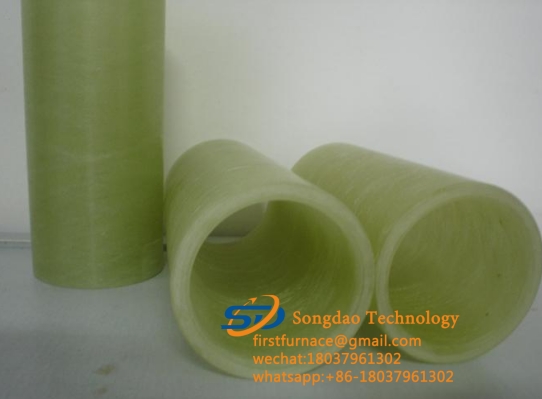

Pwodiksyon Teknoloji ak Devlopman ak Aplikasyon nan Fiberglass Tib

Pwodiksyon Teknoloji ak Devlopman ak Aplikasyon nan Fiberglass Tib

Gen twa kalite prensipal nan tib fib vè production processes: reciprocating filament winding process, continuous filament winding process and centrifugal casting process.

Pwosesis likidasyon filaman resipwòk (ki fè pati metòd la longè fiks): Nan pwosesis sa a, tank la tranpe resipwòk ak mandrin nan wotasyon, ak filaman yo long fib vè yo mete nan yon sèten ang oblik relatif ak aks la mandrin, ak ang la oksilyè. (sa vle di. Ang likidasyon an) kontwole pa rapò a vitès k ap deplase nan tank la tranpe ak vitès la wotasyon nan mandrin a, ak mouvman an tradiksyon nan tank la tranpe se kontwole pa kontwòl enfòmatik elektwomekanik. Nimewo a nan kouch likidasyon ap ogmante piti piti jiskaske epesè miray la ki fèt yo rive jwenn. Apre likidasyon an fini, résine nan atik la geri anpil. Apre geri, mandrin an retire nan tiyo a vèr.

Continuous filament winding process (belonging to continuous method): The process is that the tube passes through a feeding station that supplies resin pre-impregnated roving, chopped glass fiber reinforced plastic fiber and resin sand mixture in motion, and the tube is continuously advancing in the core mold. made in.

Centrifugal casting process (belonging to the fixed-length method): In this process, the cut glass fiber reinforced material and sand are fed into a steel mold fixed on the bearing, and the unsaturated resin with catalyst is injected into one end of the steel mold to make the steel mold. It impregnates the reinforcing material. Under the action of centrifugal force, the resin replaces the air in the fibers and fillers, thereby producing a dense composite material without pores. Due to the action of centrifugal force, the inner wall of the tube forms a smooth and clean resin-rich inner surface layer. Cures at higher temperatures. The pipe made by this method is also called glass fiber reinforced plastic sand pipe.