- 08

- Feb

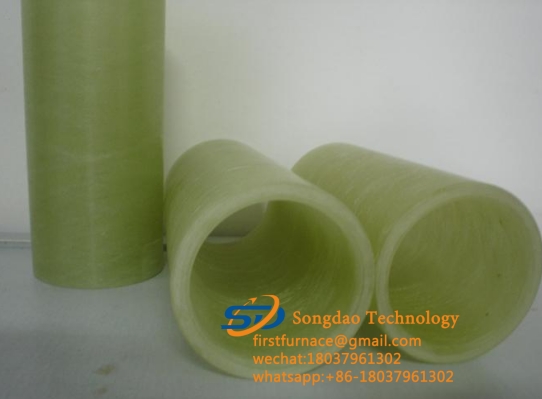

Ntau lawm Technology thiab kev loj hlob thiab kev siv ntawm Fiberglass Tube

Ntau lawm Technology thiab kev loj hlob thiab kev siv ntawm Fiberglass Tube

Muaj peb hom tseem ceeb ntawm iav fiber tube production processes: reciprocating filament winding process, continuous filament winding process and centrifugal casting process.

Reciprocating filament winding txheej txheem (raws li txoj kev ntev-ntev): Nyob rau hauv cov txheej txheem no, lub dipping tank reciprocates nrog rotating mandrel, thiab ntev fiber ntau iav filaments yog muab tso rau ntawm ib tug tej yam oblique lub kaum sab xis ntawm lub mandrel axis, thiab lub auxiliary lub kaum sab xis. (piv txwv li. Lub kaum sab xis winding) yog tswj los ntawm qhov sib piv ntawm qhov txav ceev ntawm lub dipping tank mus rau qhov kev sib hloov ceev ntawm mandrel, thiab kev hloov pauv hloov ntawm lub dipping tank yog tswj los ntawm computerized electromechanical tswj. Tus naj npawb ntawm winding khaubncaws sab nraud povtseg yog maj mam nce mus txog rau thaum tsim phab ntsa thickness. Tom qab winding tiav, cov resin nyob rau hauv tsab xov xwm yog kho tau zoo heev. Tom qab kho, lub mandrel raug tshem tawm los ntawm cov yeeb nkab fiberglass.

Continuous filament winding process (belonging to continuous method): The process is that the tube passes through a feeding station that supplies resin pre-impregnated roving, chopped glass fiber reinforced plastic fiber and resin sand mixture in motion, and the tube is continuously advancing in the core mold. made in.

Centrifugal casting process (belonging to the fixed-length method): In this process, the cut glass fiber reinforced material and sand are fed into a steel mold fixed on the bearing, and the unsaturated resin with catalyst is injected into one end of the steel mold to make the steel mold. It impregnates the reinforcing material. Under the action of centrifugal force, the resin replaces the air in the fibers and fillers, thereby producing a dense composite material without pores. Due to the action of centrifugal force, the inner wall of the tube forms a smooth and clean resin-rich inner surface layer. Cures at higher temperatures. The pipe made by this method is also called glass fiber reinforced plastic sand pipe.