- 08

- Feb

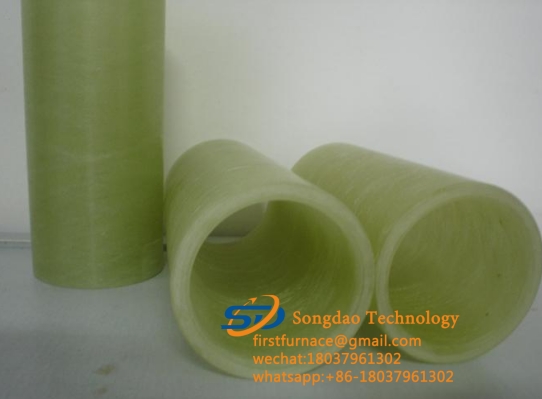

Produktionsteknologi og udvikling og anvendelse af glasfiberrør

Produktionsteknologi og udvikling og anvendelse af glasfiberrør

Der er tre hovedtyper af glasfiberrør production processes: reciprocating filament winding process, continuous filament winding process and centrifugal casting process.

Frem- og tilbagegående filamentviklingsproces (tilhørende metoden med fast længde): I denne proces kører dyppetanken frem og tilbage med den roterende dorn, og de lange glasfiberfilamenter placeres i en vis skrå vinkel i forhold til dornaksen og hjælpevinklen (dvs. viklingsvinklen) styres af forholdet mellem dyppetankens bevægelseshastighed og dornens rotationshastighed, og dyppetankens translationelle bevægelse styres af computerstyret elektromekanisk styring. Antallet af viklingslag øges gradvist, indtil den beregnede vægtykkelse er nået. Efter at viklingen er afsluttet, er harpiksen i artiklen i det væsentlige hærdet. Efter hærdning fjernes dornen fra glasfiberrøret.

Continuous filament winding process (belonging to continuous method): The process is that the tube passes through a feeding station that supplies resin pre-impregnated roving, chopped glass fiber reinforced plastic fiber and resin sand mixture in motion, and the tube is continuously advancing in the core mold. made in.

Centrifugal casting process (belonging to the fixed-length method): In this process, the cut glass fiber reinforced material and sand are fed into a steel mold fixed on the bearing, and the unsaturated resin with catalyst is injected into one end of the steel mold to make the steel mold. It impregnates the reinforcing material. Under the action of centrifugal force, the resin replaces the air in the fibers and fillers, thereby producing a dense composite material without pores. Due to the action of centrifugal force, the inner wall of the tube forms a smooth and clean resin-rich inner surface layer. Cures at higher temperatures. The pipe made by this method is also called glass fiber reinforced plastic sand pipe.