- 08

- Feb

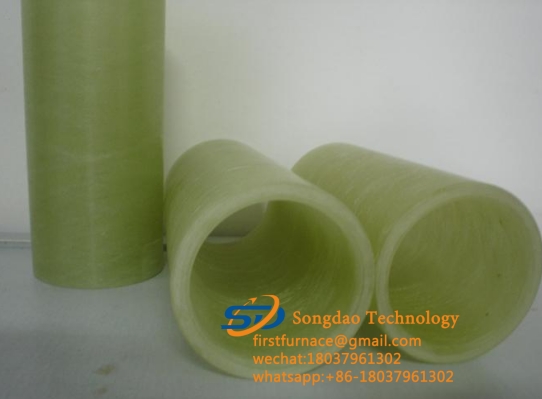

Ubuchwepheshe Bokukhiqiza Nokuthuthukiswa Nokusetshenziswa kwe-Fiberglass Tube

Ubuchwepheshe Bokukhiqiza Nokuthuthukiswa Nokusetshenziswa kwe-Fiberglass Tube

Kunezinhlobo ezintathu eziyinhloko ze- ingilazi fiber tube production processes: reciprocating filament winding process, continuous filament winding process and centrifugal casting process.

Inqubo yokugoqa i-filament ephindaphindayo (eyendlela yobude obumisiwe): Kule nqubo, ithangi lokucwilisa libuyelana ne-mandrel ejikelezayo, futhi imicu yengilazi ye-fibre ende ibekwe e-engeli ethize e-oblique ehlobene ne-axis ye-mandrel, kanye ne-engeli eyisizayo. (okungukuthi. I-engeli ejikajikayo) ilawulwa isilinganiso sejubane elinyakazayo lethangi lokucwilisa ukuya kujubane lokuzungeza le-mandrel, futhi ukunyakaza kokuhumusha kwethangi lokucwilisa kulawulwa ukulawulwa kwe-electromechanical ngekhompyutha. Inani lezendlalelo ezimazombezombe liyakhula kancane kancane kuze kufinyelelwe ubukhulu bodonga oluklanyelwe. Ngemva kokuphothula ukusonga, i-resin esihlokweni iphulukiswa kakhulu. Ngemva kokuphulukisa, i-mandrel isuswa epayipi le-fiberglass.

Continuous filament winding process (belonging to continuous method): The process is that the tube passes through a feeding station that supplies resin pre-impregnated roving, chopped glass fiber reinforced plastic fiber and resin sand mixture in motion, and the tube is continuously advancing in the core mold. made in.

Centrifugal casting process (belonging to the fixed-length method): In this process, the cut glass fiber reinforced material and sand are fed into a steel mold fixed on the bearing, and the unsaturated resin with catalyst is injected into one end of the steel mold to make the steel mold. It impregnates the reinforcing material. Under the action of centrifugal force, the resin replaces the air in the fibers and fillers, thereby producing a dense composite material without pores. Due to the action of centrifugal force, the inner wall of the tube forms a smooth and clean resin-rich inner surface layer. Cures at higher temperatures. The pipe made by this method is also called glass fiber reinforced plastic sand pipe.