- 02

- Mar

Induction heating furnace for crankshaft forging

Induction heating furnace for crankshaft forging

In order to improve the inherent quality of the crankshaft, the crankshaft production plant uses the full fiber spade forging crankshaft process. The heating before forging has always used a natural gas furnace for local heating. Due to the long heating time, the crankshaft has large crystal grains, more oxide scales, and large natural gas consumption. Energy waste is serious. In order to change the outdated production technology and equipment, the crankshaft production plant proposed to use an Induktionsheizofen to forge the crankshaft with all fiber, so a set of induction heating furnace equipment for partial heating of the crankshaft was designed and manufactured for the production plant to use.

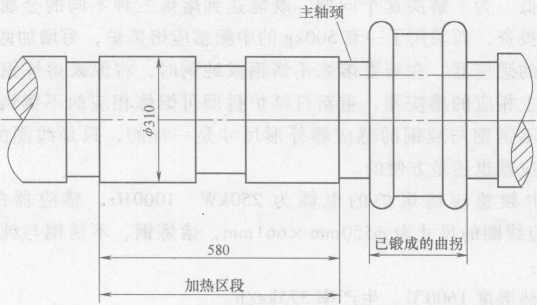

The shape and size of the local heating part of the crankshaft are shown in Figure 12-96, the maximum outer diameter is Φ310mm, the length of the heating part is Φ580mm, the material of the crankshaft is alloy steel, the heating temperature is 1200℃, the radial temperature difference is not more than 100℃, and the heating time is 20mino.

Figure 12-96 Crankshaft

The intermediate frequency inductor used for local heating of the crankshaft is single-phase, and a magnetic conductor made of silicon steel sheets is arranged around the induction coil. The coil is wound with a round hole eccentric pure copper tube 30mm x 15mm/10mm X 2mm, and a pure copper tube is wound. There are alkali-free glass ribbons, which are varnished and dried. The induction coil is compressed with a spring compression device to avoid vibration during operation. The terminal voltage of the inductor is 500V, the power is 500kW, and the installed power is 800kW. The power supply system is three-phase, and the single-phase load is balanced to the three-phase with capacitors and reactors.

According to another crankshaft manufacturer’s information, the outer diameter of the crankshaft is Φ200mm, the length of the heating part is 420mm, the heating temperature is 1200℃, and the radial temperature difference is 125 none. The grain size of the crankshaft forged with natural gas heating is 4-5 after the first heat treatment (under 4 is unqualified), the crankshaft forged by the induction heating furnace, the grain size is 5 after the first heat treatment -6 grade; the qualification rate of one-time micro forging of the crankshaft is 77% for natural gas furnace heating and 95% for intermediate frequency induction heating; the maximum curvature of the crankshaft (before straightening) is 30mm for natural gas furnace heating and 15mm for induction heating furnace ;Crankshaft heating energy consumption (converted into standard coal), natural gas furnace heating energy consumption is 2018kg/piece, and induction heating furnace energy consumption is 154kg/piece. Therefore, the heating of the crankshaft before forging is changed from natural gas furnace heating to induction heating furnace, which improves product quality, reduces energy consumption, and has obvious economic benefits. At the same time, the workshop environment is improved and labor intensity is reduced.