- 24

- Apr

Intermediate frequency induction hardening furnace

Matsakaicin matsakaici induction hardening furnace

Main technical parameters of intermediate frequency induction hardening equipment:

1. Tsarin samar da wutar lantarki: IGBT mai sanyaya iska sabon makamashi-ceton induction dumama wutar lantarki

2. Abubuwan da aka fitar a kowace awa shine 0.5-3.5 ton, kuma iyakar aikace-aikacen shine ø20-ø180mm.

3. Conveying abin nadi tebur: The axis na nadi tebur da axis na workpiece samar da wani kwana na 18-21 °. Aikin aikin yana jujjuya yayin da yake ci gaba da tafiya akai-akai don sa dumama ya zama iri ɗaya. Teburin nadi tsakanin jikin tanderun an yi shi da bakin karfe 304 ba na maganadisu ba da kuma sanyaya ruwa.

4. Rukunin tebur na Roller: ƙungiyar ciyarwa, ƙungiyar firikwensin da ƙungiyar masu fitarwa ana sarrafa su da kansu, wanda ke ba da gudummawa ga ci gaba da dumama ba tare da haifar da rata tsakanin kayan aikin ba.

5. Ikon rufaffiyar madauki: dumama da kashewa sun ɗauki tsarin sarrafa madauki na infrared Leitai na Amurka don sarrafa yanayin zafin daidai.

6. Industrial kwamfuta tsarin: real-lokaci nuni na halin yanzu yanayin aiki sigogi, workpiece siga memory, ajiya, bugu, kuskure nuni, ƙararrawa da sauran ayyuka.

7. Canjin makamashi: ana amfani da hanyar dumama + quenching, kuma yawan wutar lantarki a kowace ton shine digiri 280-320.

8. Human interface PLC automatic intelligent control system, “one-key start” production is worry-free.

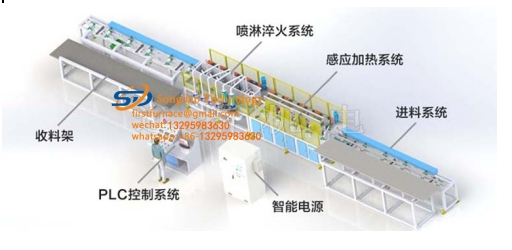

The working process of the mechanical system of the intermediate frequency induction hardening furnace:

Crane crane material → storage platform → automatic feeding mechanism → feeding roller table system → quenching induction heating system → infrared temperature measuring device → discharge roller table → spray quenching system → quenching completed → discharge roller table → cold material Organization→Receiving rack

Advantages of intermediate frequency induction hardening furnace:

1. Yana ɗaukar sabon IGBT iska mai sanyaya induction dumama ikon samar da wutar lantarki, ƙarancin wutar lantarki, ceton makamashi da kariyar muhalli, da ingantaccen samarwa.

2. The intermediate frequency induction hardening furnace adopts V-shaped rolls arranged diagonally in the transmission design to reduce radial runout.

3. The dumama gudun ne da sauri, da surface hadawan abu da iskar shaka ne kasa, da quenching tsari da aka gane a lokacin da juya dumama tsari, da kuma karfe yana da kyau straightness kuma babu lankwasawa bayan zafi magani.

4. Bayan zafi magani, da workpiece yana da daidaito na musamman high taurin, uniformity na microstructure, musamman high tauri da kuma tasiri ƙarfi.

5. The PLC touch screen control system can record and save all the process parameters of induction hardening of the workpiece, which is convenient for you to view the history of the heat treatment equipment in the future.