- 24

- Apr

Intermediate frequency induction hardening furnace

Fahita matetika induction hardening furnace

Main technical parameters of intermediate frequency induction hardening equipment:

1. Rafitra famatsiana herinaratra: famatsiana herinaratra famatsian-jiro IGBT vaovao mitsitsy angovo

2. Ny vokatra isan’ora dia 0.5-3.5 taonina, ary ny sahan’ny fampiharana dia ø20-ø180mm.

3. Fandefasana latabatra roller: Ny axe amin’ny latabatra roller sy ny axe amin’ny workpiece dia mamorona zoro 18-21 °. Mihodina ny workpiece raha mandroso amin’ny hafainganam-pandeha tsy tapaka mba hanamafisana kokoa ny hafanana. Ny latabatra roller eo anelanelan’ny vatan’ny lafaoro dia vita amin’ny vy tsy misy magnetika 304 ary mangatsiaka rano.

4. Ny fivondronan’ny latabatra roller: ny vondrona famahanana, ny vondrona sensor ary ny vondrona famoahana dia fehezin’ny tsy miankina, izay mety amin’ny fanamainana tsy tapaka nefa tsy miteraka elanelana eo amin’ny workpieces.

5. Fanaraha-maso ny mari-pana mihidy: ny fanamainana sy ny famonoana dia mampiasa ny rafitra fanaraha-maso ny thermometer infrarouge amerikana Leitai mba hifehezana tsara ny mari-pana.

6. Rafitra informatika indostrialy: fampisehoana amin’izao fotoana izao ny toetry ny asa amin’izao fotoana izao, ny fitadidiana parameter workpiece, ny fitahirizana, ny fanontana, ny fampisehoana lesoka, ny fanairana ary ny asa hafa.

7. Fiovam-po angovo: ny fomba fanafanana + famonoana dia raisina, ary ny fanjifana herinaratra isaky ny taonina dia 280-320 degre.

8. Human interface PLC automatic intelligent control system, “one-key start” production is worry-free.

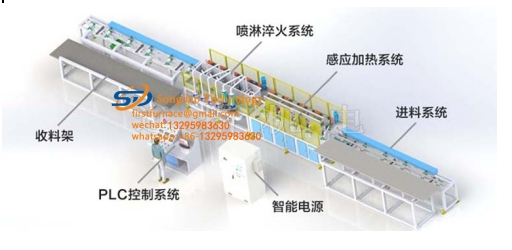

The working process of the mechanical system of the intermediate frequency induction hardening furnace:

Crane crane material → storage platform → automatic feeding mechanism → feeding roller table system → quenching induction heating system → infrared temperature measuring device → discharge roller table → spray quenching system → quenching completed → discharge roller table → cold material Organization→Receiving rack

Advantages of intermediate frequency induction hardening furnace:

1. Izy io dia mampiasa ny fanaraha-maso famatsian-jiro fanamafisam-peo IGBT misy rivotra mangatsiaka, fanjifana herinaratra ambany, fitsitsiana angovo sy fiarovana ny tontolo iainana, ary fahombiazan’ny famokarana avo lenta.

2. The intermediate frequency induction hardening furnace adopts V-shaped rolls arranged diagonally in the transmission design to reduce radial runout.

3. Ny hafainganam-pandehan’ny fanafanana dia haingana, ny oxidation ambonin’ny kely, ny quenching dingana mitranga mandritra ny fihodinan’ny fanafanana dingana, ary ny vy dia manana mahitsy tsara ary tsy miondrika aorian’ny fitsaboana hafanana.

4. Taorian’ny fitsaboana hafanana, ny workpiece dia manana ny tsy fitoviana amin’ny hamafin’ny avo dia avo, ny fitovian’ny microstructure, ny hamafin’ny avo sy ny hery fiantraikany.

5. The PLC touch screen control system can record and save all the process parameters of induction hardening of the workpiece, which is convenient for you to view the history of the heat treatment equipment in the future.