- 24

- Apr

Intermediate frequency induction hardening furnace

Soo noqnoqoshada dhexdhexaadka ah induction hardening furnace

Main technical parameters of intermediate frequency induction hardening equipment:

1. Nidaamka sahayda korontadu: hawo qaboojisay IGBT cusub oo tamar-badbaadinaysa koronto kuleyliyaha

2. Wax soo saarka saacaddii waa 0.5-3.5 tan, baaxadda codsigu waa ø20-ø180mm.

3. gudbinta miiska rullaluistuadka: dhidibka miiska rullaluistuantu iyo dhidibka shaqada ka samaysan yihiin xagal ah 18-21 °. Qalabka shaqadu waxa uu wareegtaa marka uu hore ugu socdo xawli joogto ah si uu kulaylinta uga dhigo mid labis ah. Miiska rullaluistuadka ee u dhexeeya maydadka foornada wuxuu ka samaysan yahay 304 bir ah oo aan bir ah oo bir ah oo aan bir ah lahayn iyo biyo qabow.

4. Kooxaynta miiska rullalusha: kooxda quudinta, kooxda dareemayaasha iyo kooxda sii daaya ayaa si madaxbannaan loo xakameeyaa, taas oo u sahlaysa kulaylka joogtada ah iyada oo aan keenin farqiga u dhexeeya qaybaha shaqada.

5. Xakamaynta wareegga-xiran ee heerkulka: kulaylinta iyo deminta waxay qaataan Heerkulbeegga Leitai infrared ee American Leitai nidaamka xakamaynta wareegga xiran si si sax ah loo xakameeyo heerkulka.

6. Nidaamka kombuyuutarrada warshadaha: soo bandhigida waqtiga dhabta ah ee xaaladda hadda jirta ee xuduudaha shaqada, xusuusta cabbirka workpiece, kaydinta, daabacaadda, bandhigga cilladda, alaarmiga iyo hawlaha kale.

7. Bedelka tamarta: kuleylinta + habka deminta ayaa la qaatay, isticmaalka korontada tan tan waa 280-320 darajo.

8. Human interface PLC automatic intelligent control system, “one-key start” production is worry-free.

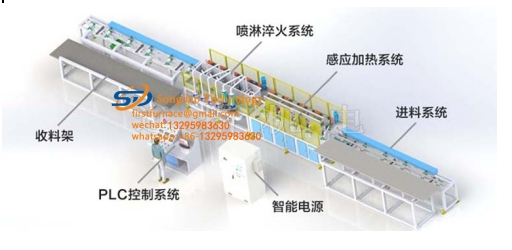

The working process of the mechanical system of the intermediate frequency induction hardening furnace:

Crane crane material → storage platform → automatic feeding mechanism → feeding roller table system → quenching induction heating system → infrared temperature measuring device → discharge roller table → spray quenching system → quenching completed → discharge roller table → cold material Organization→Receiving rack

Advantages of intermediate frequency induction hardening furnace:

1. Waxay qabataa IGBT cusub oo qaboojiye hawo qaboojiye induction kuleyliyaha korantada korantada, isticmaalka tamarta yar, badbaadinta tamarta iyo ilaalinta deegaanka, iyo waxtarka wax soo saarka sare.

2. The intermediate frequency induction hardening furnace adopts V-shaped rolls arranged diagonally in the transmission design to reduce radial runout.

3. Xawaaraha kuleylku waa mid degdeg ah, oksaydhka dusha sare waa ka yar yahay, habka deminta waxaa la ogaaday inta lagu jiro habka kuleylka wareega, iyo birta ayaa leh toosan wanaagsan oo aan leexin ka dib daaweynta kulaylka.

4. Daawaynta kulaylka ka dib, workpiece waxay leedahay joogteynta engegnaanta aadka u sarreeya, isku mid ahaanshaha qaab-dhismeedka yar-yar, adkaanta aadka u sarreeya iyo xoogga saameynta.

5. The PLC touch screen control system can record and save all the process parameters of induction hardening of the workpiece, which is convenient for you to view the history of the heat treatment equipment in the future.