- 24

- Apr

Isithando somlilo esiqinisa imvamisa emaphakathi

Imvamisa ephakathi isithando somlilo sokungeniswa

Amapharamitha amakhulu wezobuchwepheshe wemishini yokuqinisa i-intermediate frequency induction:

1. Isistimu yokuphakela amandla: I-IGBT epholile emoyeni entsha yokonga amandla kagesi wokushisisa

2. Okukhiphayo ngehora ngamathani angu-0.5-3.5, futhi ububanzi bokusebenza ngu-ø20-ø180mm.

3. Ithebula le-roller elihambisayo: I-axis yetafula le-roller kanye ne-axis ye-workpiece yakha i-engeli ye-18-21 °. I-workpiece iyazungeza ngenkathi iqhubekela phambili ngesivinini esingaguquki ukwenza ukushisa kube okufanayo. Ithebula le-roller phakathi kwemizimba yesithando somlilo lenziwe ngensimbi engagqwali engama-304 engeyona i-magnetic futhi ipholiswe ngamanzi.

4. Ukuqoqwa kwetafula le-roller: iqembu lokuphakelayo, iqembu lezinzwa kanye neqembu lokukhipha lilawulwa ngokuzimela, elihambisana nokushisa okuqhubekayo ngaphandle kokubangela igebe phakathi kwama-workpieces.

5. Ukulawula izinga lokushisa kweluphu evaliwe: ukushisisa nokucisha kusebenzisa i-American Leitai infrared thermometer yokulawula iluphu ukuze ulawule ngokunembile izinga lokushisa.

6. Uhlelo lwekhompiyutha yezimboni: isibonisi sesikhathi sangempela sesimo samanje semingcele yokusebenza, inkumbulo yepharamitha ye-workpiece, isitoreji, ukuphrinta, isibonisi samaphutha, i-alamu neminye imisebenzi.

7. Ukuguqulwa kwamandla: indlela yokushisa + yokucisha iyamukelwa, futhi ukusetshenziswa kukagesi ngethani ngama-280-320 degrees.

8. Isixhumi esibonakalayo somuntu se-PLC uhlelo oluzenzakalelayo lokulawula oluhlakaniphile, ukukhiqizwa “kokhiye owodwa” akukhathazeki.

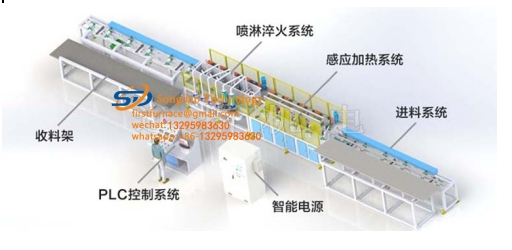

Inqubo yokusebenza yesistimu yemishini yesithando somlilo esimaphakathi sokungenisa imvamisa:

Impahla ye-crane crane → isiteji sokugcina → indlela yokuphakela ezenzakalelayo → uhlelo lwetafula lokuphakelayo → isistimu yokushisisa yokungeniswa → idivayisi yokulinganisa izinga lokushisa le-infrared → itafula lokulahla → uhlelo lokucisha isifutho → ukucisha kuqediwe → itafula lokulahla → into ebandayo Inhlangano→Ukuthola irack

Izinzuzo ze-intermediate frequency induction hardening furnace:

1. Yamukela isilawuli esisha sokushisisa sokungenisa umoya se-IGBT esipholile, ukusetshenziswa kwamandla okuphansi, ukonga amandla nokuvikelwa kwemvelo, kanye nokusebenza kahle kokukhiqiza okuphezulu.

2. Isithando somlilo esimaphakathi sokungeniswa kwefrikhwensi sithatha amaroli amise okwe-V ahlelwe ngokudayagonali kumklamo wokudlulisela ukunciphisa ukuphuma kweradial.

3. Isivinini sokushisa siyashesha, i-oxidation yangaphezulu incane, inqubo yokucisha iyabonakala ngesikhathi senqubo yokushisa ejikelezayo, futhi insimbi inokuqondisa okuhle futhi akukho ukugoba ngemva kokwelashwa kokushisa.

4. Ngemuva kokwelashwa okushisa, umsebenzi wokusebenza unokuvumelana kokuqina okuphezulu kakhulu, ukufana kwe-microstructure, ukuqina okuphezulu kakhulu namandla okuthinta.

5. Isistimu yokulawula isikrini sokuthinta i-PLC ingarekhoda futhi igcine yonke imingcele yenqubo yokuqina kwe-induction ye-workpiece, ekulungele ukubuka umlando wemishini yokushisa ukushisa esikhathini esizayo.