- 24

- Apr

Intermediate frequency induction hardening furnace

Maqhubu a lipakeng induction hardening furnace

Main technical parameters of intermediate frequency induction hardening equipment:

1. Sistimi ea phepelo ea motlakase: moea o pholileng ka moea oa IGBT o mocha oa ho boloka matla a ho futhumatsa motlakase

2. Sephetho ka hora ke lithane tse 0.5-3.5, ‘me sebaka sa kopo ke ø20-ø180mm.

3. Tafole e tsamaisang rolara: Mohala oa tafole ea rolara le axis ea workpiece e etsa angle ea 18-21 °. Sebaka sa mosebetsi se potoloha ha se ntse se tsoela pele ka lebelo le tsitsitseng ho etsa hore mocheso o be le seaparo se lekaneng. Tafole ea rolara pakeng tsa ‘mele oa sebōpi e entsoe ka tšepe e sa hloekang ea 304 e se nang makenete le e pholileng ka metsi.

4. Sehlopha sa li-roller table: sehlopha sa ho fepa, sehlopha sa sensor le sehlopha sa ho ntša li laoloa ka mokhoa o ikemetseng, e leng se loketseng ho futhumatsa ho tsoelang pele ntle le ho baka lekhalo pakeng tsa li-workpieces.

5. Taolo e koetsoeng ea mocheso: ho futhumatsa le ho tima ho amohela mokhoa oa ho laola mocheso oa American Leitai infrared thermometer ho laola mocheso ka nepo.

6. Tsamaiso ea k’homphieutha ea indasteri: pontšo ea nako ea sebele ea boemo ba hona joale ba maemo a ho sebetsa, mohopolo oa parameter ea workpiece, polokelo, khatiso, pontšo ea phoso, alamo le mesebetsi e meng.

7. Phetoho ea matla: mokhoa oa ho futhumatsa + oa ho tima o amoheloa, ‘me tšebeliso ea motlakase ka tonne ke likhato tse 280-320.

8. Human interface PLC automatic intelligent control system, “one-key start” production is worry-free.

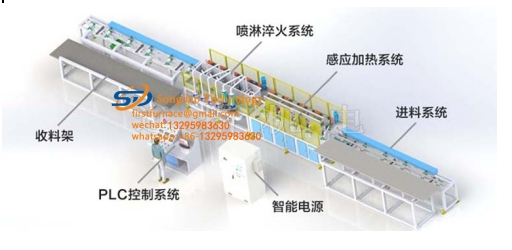

The working process of the mechanical system of the intermediate frequency induction hardening furnace:

Crane crane material → storage platform → automatic feeding mechanism → feeding roller table system → quenching induction heating system → infrared temperature measuring device → discharge roller table → spray quenching system → quenching completed → discharge roller table → cold material Organization→Receiving rack

Advantages of intermediate frequency induction hardening furnace:

1. E amohela taolo e ncha ea ho futhumatsa moea oa IGBT ea ho futhumatsa moea, ho sebelisoa ha matla a fokolang, ho boloka matla le ho sireletsa tikoloho, le katleho e phahameng ea tlhahiso.

2. The intermediate frequency induction hardening furnace adopts V-shaped rolls arranged diagonally in the transmission design to reduce radial runout.

3. Lebelo la ho futhumatsa le potlakile, oxidation ea holim’a metsi e fokotsehile, mokhoa oa ho tima o etsoa nakong ea ho futhumatsa ho potoloha, ‘me tšepe e na le ho otloloha ho hotle ebile ha ho na ho khumama ka mor’a phekolo ea mocheso.

4. Ka mor’a phekolo ea mocheso, workpiece e na le ho lumellana ha boima bo phahameng ka ho fetisisa, ho tšoana ha microstructure, ho thata ka ho fetisisa le matla a ts’usumetso.

5. The PLC touch screen control system can record and save all the process parameters of induction hardening of the workpiece, which is convenient for you to view the history of the heat treatment equipment in the future.