- 24

- Apr

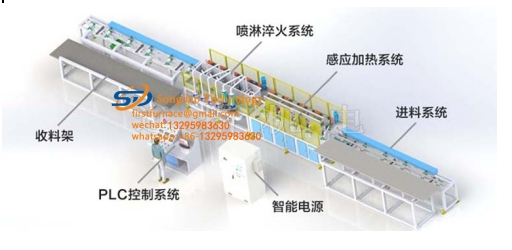

Intermediate frequency induction hardening furnace

Intermediate frequency induction hardening furnace

Main technical parameters of intermediate frequency induction hardening equipment:

1. Power supply system: air-cooled IGBT new energy-saving induction heating power supply

2. The output per hour is 0.5-3.5 tons, and the scope of application is ø20-ø180mm.

3. Conveying roller table: The axis of the roller table and the axis of the workpiece form an angle of 18-21°. The workpiece rotates while moving forward at a constant speed to make the heating more uniform. The roller table between the furnace bodies is made of 304 non-magnetic stainless steel and water-cooled.

4. Roller table grouping: the feeding group, the sensor group and the discharging group are independently controlled, which is conducive to continuous heating without causing a gap between the workpieces.

5. Temperature closed-loop control: heating and quenching adopt the American Leitai infrared thermometer closed-loop control system to accurately control the temperature.

6. Industrial computer system: real-time display of the current state of working parameters, workpiece parameter memory, storage, printing, fault display, alarm and other functions.

7. Energy conversion: heating + quenching method is adopted, and the electricity consumption per ton is 280-320 degrees.

8. Human interface PLC automatic intelligent control system, “one-key start” production is worry-free.

The working process of the mechanical system of the intermediate frequency induction hardening furnace:

Crane crane material → storage platform → automatic feeding mechanism → feeding roller table system → quenching induction heating system → infrared temperature measuring device → discharge roller table → spray quenching system → quenching completed → discharge roller table → cold material Organization→Receiving rack

Advantages of intermediate frequency induction hardening furnace:

1. It adopts new IGBT air-cooled induction heating power supply control, low power consumption, energy saving and environmental protection, and high production efficiency.

2. The intermediate frequency induction hardening furnace adopts V-shaped rolls arranged diagonally in the transmission design to reduce radial runout.

3. The heating speed is fast, the surface oxidation is less, the quenching process is realized during the rotating heating process, and the steel has good straightness and no bending after heat treatment.

4. After the heat treatment, the workpiece has the consistency of extremely high hardness, uniformity of microstructure, extremely high toughness and impact strength.

5. The PLC touch screen control system can record and save all the process parameters of induction hardening of the workpiece, which is convenient for you to view the history of the heat treatment equipment in the future.