- 14

- Jun

Yadda ake sarrafa nakasawa da fashe kayan aikin kashe mitoci masu yawa yayin kashewa

Yadda za a sarrafa nakasawa da fatattaka na high m quenching kayan aiki a lokacin quenching

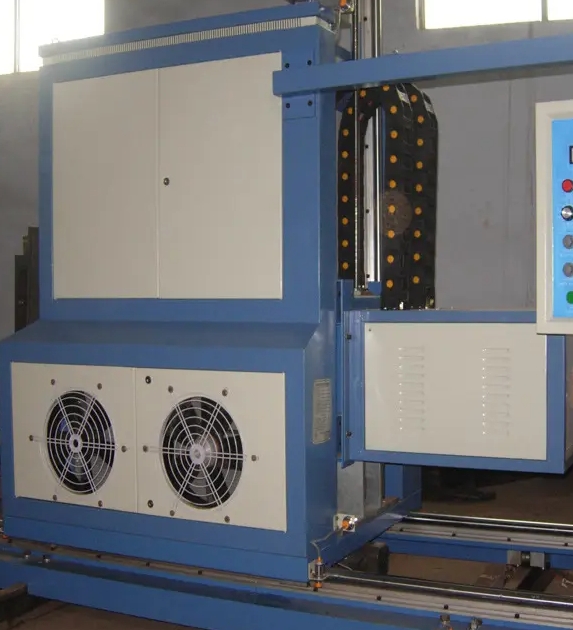

Saboda haɗuwa da tasirin tsarin tsarin da damuwa na zafi, kayan aikin yankan karfe masu sauri suna sau da yawa lalacewa da fashe, kuma sun fi shahara ga manyan kayan aikin yankan, hadaddun da siriri.

Akwai dalilai da yawa na nakasawa da fatattaka, irin su sanyi aiki danniya a yankan kayan aikin kafin zafi magani, asali fasa, tsanani carbide segregation, high mita quenching zazzabi ma high, ma sauri sanyaya, wanda bai kai ba tsaftacewa da untimely tempering, da dai sauransu fashe. Idan rarrabuwar carbide a cikin ƙarfe mai sauri ya wuce matakin da aka ƙayyade, a fili zai haifar da lalacewa da fashewa. The segregation na carbides zai haifar da nakasawa da fatattaka, domin a karkashin wasu quenching tsari yanayi, da taro juzu’i na carbon da kuma mataki na alloying inda carbides aka deposited ne mafi girma fiye da wadanda a sauran yankunan, don haka Ms nuna akwai ƙananan, (high high). Mitar walda na’ura) yana haifar da canji na austenite zuwa martensite a yankuna daban-daban, wanda ke ƙara haɓakar tsarin. Sakamakon danniya, ko a lokacin quenching ko tempering, na iya haifar da nakasawa ko fashe na workpiece a wurin rabuwar carbide.

Domin rage nakasawa da fashewa, dole ne a bincika albarkatun ƙasa sosai kuma dole ne a kula da zafin zafin da ke kashewa. Don yankan kayan aikin tare da sifofi masu rikitarwa, yakamata a yi amfani da preheating da yawa da hanyoyin quenching da yawa, wanda zai iya rage nakasar kayan aikin. Bugu da ƙari, za a iya amfani da maƙallan da suka dace don sarrafa nakasawa da rage raguwa.