- 24

- Apr

Ọkụ na-eme ka obi sie ike nke etiti oge

Ugboro ugboro induction hardening ọkụ

Isi teknuzu paramita nke etiti oge induction akụrụngwa hardening:

1. Usoro ọkụ ọkụ: ikuku jụrụ IGBT ọhụrụ ike na-azọpụta ike ọkụ ọkụ ọkụ

2. Ihe mmepụta kwa elekere bụ 0.5-3.5 tọn, na njedebe nke ngwa bụ ø20-ø180mm.

3. Conveying roller table: The axis of the roller table and the axis of workpiece etolite n’akuku nke 18-21 °. The workpiece na-atụgharị mgbe ọ na-aga n’ihu na ọsọ ọsọ mgbe niile iji mee ka ikpo ọkụ dịkwuo edo. Tebụlụ rola n’etiti ahụ ọkụ bụ nke 304 igwe anaghị agba nchara na mmiri jụrụ oyi.

4. Roller table grouping: otu nri nri, ihe mmetụta na ndị na-ebugharị na-achịkwa onwe ha, nke na-eme ka ikpo ọkụ na-aga n’ihu n’emeghị ka ọdịiche dị n’etiti workpieces.

5. Okpomọkụ na-emechi akaghị njikwa: kpo oku na quenching nakweere American Leitai infrared temometa mechiri emechi-loop akara usoro iji jikwaa nke ọma okpomọkụ.

6. Industrial kọmputa usoro: ezigbo oge ngosi nke ugbu a na ọnọdụ nke na-arụ ọrụ parameters, workpiece oke ebe nchekwa, nchekwa, obibi, mmejọ ngosi, mkpu na ndị ọzọ ọrụ.

7. Ntugharị ike: a na-anabata usoro ikpo ọkụ + ọkụ, na ọkụ eletrik kwa ton bụ ogo 280-320.

8. Human interface PLC akpaka ọgụgụ isi akara usoro, “otu-isi mmalite” mmepụta bụ nchegbu-free.

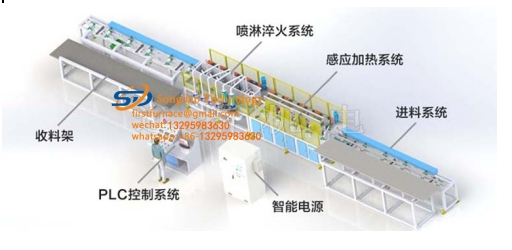

Usoro arụ ọrụ nke sistemu igwe nke ọkụ induction hardening ugboro nke etiti:

Ihe crane crane → ikpo okwu nchekwa → sistemu nri akpaaka → sistemu okpokoro nri → quenching induction kpo oku sistemu → ngwaọrụ nha infrared → okpokoro mkpọpu igwe → sistem quenching → quenching dechara → okpokoro mwepu → ihe eji eme oyi → Nnata ogbe

Uru nke ọkụ ọkụ induction ugboro ugboro nke etiti:

1. Ọ na-anabata IGBT ọhụrụ ikuku jụrụ oyi na-ekpo ọkụ ọkụ ọkụ ọkụ, obere ike oriri, nchekwa ike na nchebe gburugburu ebe obibi, na mmepụta mmepụta ihe dị elu.

2. Ọkụ dị n’etiti induction hardening na-ekpo ọkụ na-anabata mpịakọta ụdị V nke a haziri diagonally na nhazi nnyefe iji belata radial runout.

3. Igwe ọkụ na-ekpo ọkụ na-agba ọsọ ngwa ngwa, oxidation elu dị ntakịrị, usoro nkwụsị ahụ na-enweta n’oge usoro ikpo ọkụ na-agbanwe agbanwe, na ígwè ahụ nwere ezigbo nkwụsi ike na enweghị nkwụsị mgbe ọgwụgwọ okpomọkụ gasịrị.

4. Mgbe ọgwụgwọ okpomọkụ gasịrị, workpiece nwere nguzosi ike nke oke ike siri ike, ịdị n’otu nke microstructure, oke ike siri ike na ike mmetụta.

5. The PLC ihuenyo mmetụ njikwa usoro nwere ike idekọ na-azọpụta niile usoro parameters nke induction hardening nke workpiece, nke bụ adaba n’ihi na ị na-ele akụkọ ihe mere eme nke okpomọkụ ọgwụgwọ ngwá n’ọdịnihu.