- 15

- Feb

Bukatun fasaha don ƙwaƙƙwaran ƙira na induction narkewar tanderun

Bukatun fasaha don ƙwaƙƙwaran ƙira na induction narkewar tanderun

Dole ne ƙirar ƙira ta kasance tana da isasshen ƙarfi yayin aikin gini da ɓacin rai, kuma kada ta zama nakasu yayin aikin ginin don tabbatar da cewa zai iya watsa kuzarin girgiza zuwa kayan da aka rufe don ƙaddamar da kayan rufi. Yanayin zafi na kayan rufi dole ne ya kasance a cikin tsarin sintiri. Ba za a narkar da shi ba kafin samuwar, kuma ba zai zama nakasu a cikin gida ko narke ba ta tasirin filin maganadisu.

Da zarar yanayin da ke sama ya faru, zai haifar da cika kayan da aka rufe a cikin ɓoyayyen da aka samu ta hanyar lalacewa na mold, wanda zai haifar da raguwa a cikin girman rufin, ta haka ne ya shafi ƙarfin rufin kuma ya rage rayuwar da ta dace. rufi.

Dangane da gwaninta mai amfani, ƙwanƙolin murhun wuta mai nauyin tan 6 yana amfani da vibrator na lantarki don girgiza asalin 6mm farantin karfe mai ƙyalƙyali zuwa 10mm a ainihin lokacin, kuma 20-ton induction narkewa tanderun ƙura yana amfani da 10mm lokacin farin ciki A3 farantin karfe don tabbatar da tabbatar da walƙiya. cewa crucible mold yana da ƙarfi ƙarfi , The vibrator ba shi da sauki ga nakasu a lokacin guduma da bugun tsari, da kuma vibration makamashi za a iya canjawa wuri zuwa ga tanderun rufi abu ta hanyar crucible mold don cimma manufar compacting da tanderun rufi, game da shi tabbatar. Ƙarfin wutar lantarki da kuma tabbatar da rayuwar sabis na rufin tanderun.

Halayen tsarin ƙirar ƙirar ƙira suna da tasiri kai tsaye ga rayuwar rufin tanderun, don haka kula da waɗannan abubuwan:

1. Kewaye na babban jiki na crucible mold

Za’a iya tsara kewaye da babban jikin ƙwanƙwasa ƙirƙira don samun gangara tare da saman bakin ciki da ƙasa mai kauri, ko madaidaiciyar siffar cylindrical ba tare da gangara ba. Ana sarrafa gangara gabaɗaya a 1 ~ 4°, girman madaidaicin ƙwanƙwasa cylindrical crucible mold yakamata ya zama mafi girma ko daidai da amintaccen kauri na ɓangaren bakin ciki na rufin tanderun.

2. Ƙaddamar da tsayin daɗaɗɗen ƙura

An yi imani da cewa tsayin ƙwanƙwasa ƙura daga ƙasan kauri na murhu zuwa girman ɓangaren sama na jikin tanderun. Duk da haka, ya kamata a yi la’akari da waɗannan abubuwan gabaɗaya a cikin ainihin tsari: ingancin narkewa, kayan narkewa, sassan lalata na tanderun mitar matsakaici, da murfin murhu.

A karkashin yanayi na al’ada, ƙasan tsakiyar mitar tanderu don samar da baƙin ƙarfe mai launin toka ko baƙin ƙarfe ductile ba shi da lalacewa sosai (kimanin 30-50mm), kuma ana iya danna saman gefen ƙananan jujjuyawar nada induction.

A lokaci guda kuma, tsayin dukkan nau’in crucible ya kamata ya zama nisa daga saman jirgin sama na murhu na ƙasa zuwa tsayin tsayin tanderun tare da jirgin sama da tsayin kusan 50mm sama da tanderun tare da jirgin. Wannan tsayin yana dacewa da cikakken tanderun ƙarfe baƙin ƙarfe sintering rufin tanderun, kuma takamaiman tsayin daka ba zai shafi Rufe murfin tanderun ba.

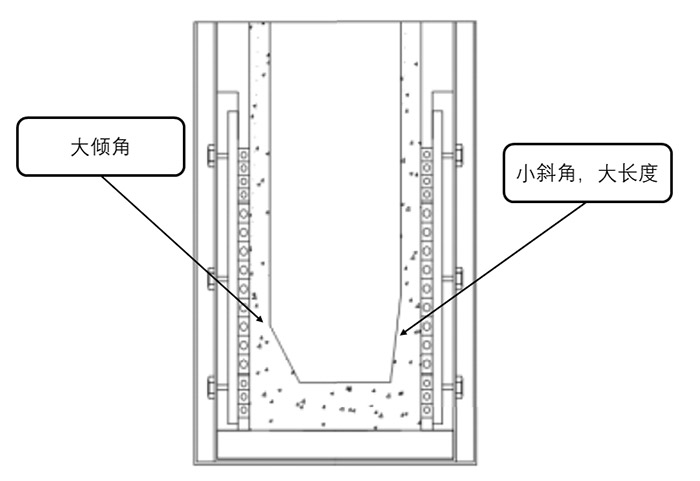

3. Girma da siffar kusurwa

Wannan yana da sauƙin samarwa; ƙafar giwa; lahani, kuma yana ƙarƙashin rufin tanderun na dogon lokaci don a nannade shi da narkakken ƙarfe kuma ba za a iya gani ba, don haka dole ne a tsara shi daidai. Lokacin da kusurwar karkata ya yi girma, za a iya ƙara kauri daga cikin rufin, amma yana da sauƙi don sa suturar kullin, kuma lalacewar inji na ciyarwa yana da tsanani; kuma idan aka bi shi; ƙananan kusurwar bevel yana da girma; bayan ka’ida, layi na baya yana da sauƙi a kulle a nan. Yana da ƙima, kuma yana iya yin tasiri mai ƙarfi na anti-pumping, juriya na lalata da juriya na matsawa a gangaren rufin tanderun yayin aikin narkewa, don haka guje wa lahani na “ƙafafun giwa” da haɓaka rayuwar sabis na rufin tanderun.

4. Hana ramin huɗa da siffar ƙasa

4. Hana ramin huɗa da siffar ƙasa

Diamond-dimbin yawa ramukan ya kamata a yadi a kasa, gangara da gefen bango na crucible mold a wani tazara na 200 ~ 300mm, wanda shi ne conducive zuwa sallama da danshi a cikin tanderun rufi abu a lokacin yin burodi mataki da kuma ƙara juriya, da kuma yana inganta tasirin dumama da yin burodi.

Diamita na rami ya fi dacewa 3mm. Idan ya yi ƙanƙara sosai, tasirin shaye-shaye zai zama mara kyau, kuma idan ya yi girma sosai, zai haifar da fitar da adadin foda mai yawa daga cikin rami lokacin da tanderun ta girgiza.

Ba za a iya komawa cikin ƙasa na ƙwanƙwasa ƙura ba a ciki, a kwance, ko protrude kusan 1mm daga tsakiya, don kauce wa tazarar iska da damuwa na tsarin a kasan tanderun bayan an gina tanderun, wanda zai iya haifar da “kasa. fashewa” a lokacin yin burodi da kuma sintering.

5. Sauran

Duk welds dole ne a goge su da kyau kuma ba a yarda da sauran abubuwan walda ko sasanninta masu kaifi ba; da haƙuri da concentricity na waje da’irar crucible mold ya kamata a sarrafa a cikin 5mm; Dole ne a harbe ƙwanƙwaran ƙwayar ƙwayar cuta kafin amfani.