- 15

- Feb

Zvido zvehunyanzvi zve crucible mold ye induction melting furnace

Zvido zvehunyanzvi zve crucible mold ye induction melting furnace

Iyo crucible mold inofanirwa kuve nesimba rakakwana panguva yekuvaka uye sintering process, uye haifanirwe kukanganiswa panguva yekuvaka kuti ive nechokwadi chekuti inogona kufambisa simba rekuzunguza kune lining material kuti ibate iyo lining material. Iyo inopisa pamusoro peiyo lining material inofanira kunge iri mu sintering process. Iyo haizonyungudutswa isati yaumbwa, uye haizove yakaremara munharaunda kana kunyungudutswa nesimba remagineti.

Kana mamiriro ari pamusoro aitika, achaita kuti iyo lining zvinhu zvizadzwe muvhu rakaumbwa nekushanduka kwe mold, zvichikonzera kuderera kwehuremu hweiyo lining, zvichikanganisa kusimba kweiyo lining uye kupfupisa hupenyu hweiyo. lining.

Zvinoenderana neruzivo runoshanda, iyo 6-ton yevira crucible mold inoshandisa yemagetsi vibrator kuzunguza yekutanga 6mm simbi ndiro crucible mold kusvika 10mm munguva chaiyo, uye 20-ton induction inonyunguduka muchoto crucible mold inoshandisa 10mm gobvu A3 simbi plate welding kuve nechokwadi. kuti iyo crucible mold ine simba rakasimba , Iyo vibrator haisi nyore kukanganisa panguva yekurova uye kurova, uye iyo vibration simba inogona kuendeswa kune yevira yekubikira zvinhu kuburikidza ne crucible mold kuzadzisa chinangwa chekubatanidza tambo yevira, nekudaro kuve nechokwadi. kusimba kwechigadziko chechoto uye kuve nechokwadi chehupenyu hwebasa rembambo yevira.

Mamiriro ekuumbwa kweiyo crucible mold ane tarisiro yakananga pahupenyu hwebiravira rechoto, saka teerera kune zvinotevera zvinhu:

1. Kutenderera kwemuviri mukuru we crucible mold

Iyo denderedzwa yemuviri mukuru weiyo crucible mold inogona kugadzirwa kuve nemateru ane yakaonda kumusoro uye yakadzika pasi, kana yakatwasuka cylindrical chimiro pasina mutsetse. Kutsetseka kunowanzo kudzorwa pa 1 ~ 4 °, saizi yeyakatwasuka cylindrical crucible mold inofanira kunge yakakura kupfuura kana kuenzana nehukobvu hwakachengeteka hwechikamu chakatetepa chebira rechoto.

2. Kutsunga kwehurefu hwemuumbi we crucible

Zvinowanzotendwa kuti kureba kweiyo crucible mold kubva pasi pechoto chebira ukobvu kusvika kuhukuru hwechikamu chepamusoro chechoto chevira. Nekudaro, izvo zvinotevera zvinhu zvinofanirwa kutariswa zvizere mukuita chaiko: kunyatsoita kunyungudika, kunyungudutsa zvinhu, lining corrosion zvikamu zvepakati frequency choto, uye chivharo chechoto.

Mumamiriro ezvinhu akajairwa, pasi peiyo yepakati frequency furemu yekugadzira grey iron kana ductile iron haina kuonda zvakanyanya (inenge 30-50mm), uye mupendero wepamusoro wekutendeuka kwepasi kweiyo induction coil inogona kudzvanywa.

Panguva imwecheteyo, kureba kwese crucible mold kunofanirwa kunge kuri chinhambwe kubva kumusoro kwechoto chepasi lining kusvika kune yakatwasuka kureba kwechoto pamwe nendege pamwe nehupamhi hunosvika 50mm pamusoro pechoto pamwe nendege. Kukwirira uku kunobatsira kune yakazara choto simbi sintering choto lining, uye yakananga kureba haikanganisi Vhara choto chivharo.

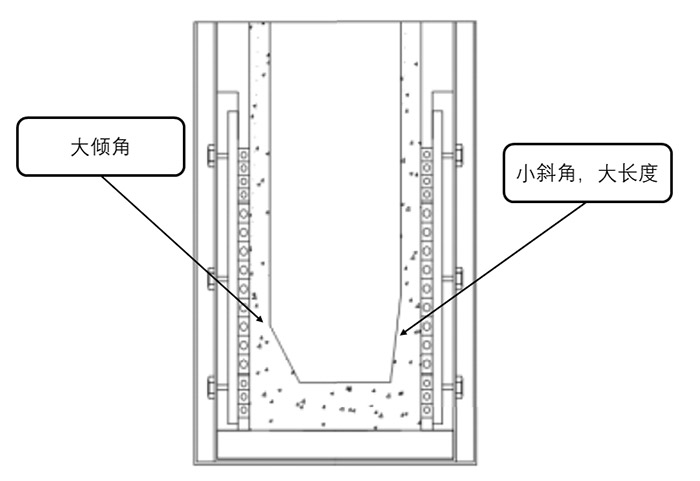

3. Ukuru uye chimiro chekona

Izvi zviri nyore kugadzira; tsoka dzenzou; kukanganisa, uye iri pasi pemucheka wechoto kwenguva yakareba kuti iputirwe musimbi yakanyungudutswa uye haigoni kuonekwa, saka inofanira kugadzirwa maererano. Kana kona yekurerekera yakakura kwazvo, hupamhi hwechigadziko hunogona kuwedzerwa, asi zviri nyore kuita kuti jira rive mafundo, uye kukanganisa kwemagetsi kwekudyisa zvakare kwakanyanya; uye kana yateverwa; diki bevel angle yakakura; mushure memusimboti, iyo yekupedzisira lining iri nyore kupfundo pano. Iyo yakabatana, uye inogona kunyatso shandisa simba rekurwisa kupomba, kuonda kwekupomba uye kumanikidza kuramba pamateru evira rechoto panguva yekunyunguduka, nekudaro kudzivirira kukanganisa kwe “tsoka dzenzou” uye kuwedzera hupenyu hwesevhisi yebira rechoto.

4. Dhonza gomba remhepo uye chimiro chepasi

4. Dhonza gomba remhepo uye chimiro chepasi

Maburi akaenzana nedhaimani anofanirwa kudhirwa pazasi, pamawere uye pamadziro emadziro eiyo crucible mold pane imwe nguva ye200 ~ 300mm, iyo inobatsira pakubuda kwehunyoro muchoto chekubikira zvinhu panguva yekubikira uye inowedzera kuramba, uye. inovandudza kupisa uye kubheka maitiro.

Iyo dhayamita yegomba zviri nani 3mm. Kana ikanyanya kudiki, iyo yekupedza simba ichave yakashata, uye kana yakanyanya kukura, ichaita kuti huwandu hukuru hwehupfu hubviswe kubva mugomba kana choto ichizunguzika.

Iyo yepasi ndege ye crucible mold haigone kudzoreredzwa mukati, yakatwasuka, kana kubhururuka inosvika 1mm kubva pakati, kuitira kudzivirira gomba remhepo uye kushushikana kwechimiro pazasi pechoto mushure mekuvakwa kwevira, izvo zvinogona kukonzera “pasi. kuputika” panguva yekubika nekupisa.

5. Vamwe vose

Welds ese anofanirwa kukwenenzverwa zvakanaka uye hapana welding solvent kana makona akapinza anotenderwa; kushivirira uye concentricity yekunze kwedenderedzwa re crucible mold inofanira kudzorwa mukati me5mm; iyo crucible mold inofanira kupfurwa yakaputika isati yashandiswa.