- 15

- Feb

Cov txheej txheem kev cai rau cov pwm crucible ntawm induction melting rauv

Cov txheej txheem kev cai rau cov pwm crucible ntawm induction melting rauv

Lub crucible pwm yuav tsum muaj lub zog txaus thaum lub sij hawm tsim kho thiab sintering txheej txheem, thiab nws yuav tsum tsis txhob deformed thaum lub sij hawm tsim kho txheej txheem los xyuas kom meej tias nws muaj peev xwm xa lub zog vibration rau hauv ob sab phlu cov ntaub ntawv rau compact lub hauv ob sab phlu khoom. Qhov kub ntawm cov khoom siv hauv ob sab phlu yuav tsum nyob rau hauv cov txheej txheem sintering. Nws yuav tsis tau yaj ua ntej tsim, thiab yuav tsis nyob hauv zos deformed los yog melted los ntawm lub zog ntawm magnetic teb.

Thaum cov xwm txheej saum toj no tshwm sim, nws yuav ua rau cov khoom siv hauv ob sab phlu yuav tsum tau ntim rau hauv qhov khoob uas tsim los ntawm kev deformation ntawm cov pwm, uas ua rau txo qhov ntom ntawm lub hauv ob sab phlu, yog li cuam tshuam rau lub zog ntawm lub hauv ob sab phlu thiab shortening lub neej ntawm cov ntaub. hauv ob sab phlu.

Raws li kev paub dhau los, 6-tuj rauv crucible pwm siv lub tshuab hluav taws xob vibrator los co cov thawj 6 hli steel phaj crucible pwm rau 10 hli nyob rau lub sijhawm, thiab 20-tuj induction melting rauv crucible pwm siv 10 hli tuab A3 steel phaj vuam los xyuas kom meej. tias cov pwm crucible muaj lub zog muaj zog, lub vibrator tsis yooj yim rau deform thaum lub sij hawm hammering thiab ntaus, thiab lub zog vibration tuaj yeem hloov mus rau hauv cov khoom siv hauv lub tshuab hluav taws xob los ntawm cov pwm crucible kom ua tiav lub hom phiaj ntawm compacting lub qhov cub hauv ob sab phlu, yog li xyuas kom meej. lub zog ntawm lub cub tawg hauv ob sab phlu thiab ua kom lub neej kev pab cuam ntawm lub qhov cub hauv ob sab phlu.

The structural characteristics of the crucible mold have a direct impact on the life of the furnace lining, so pay attention to the following aspects:

1. The circumference of the main body of the crucible mold

Lub voj voog ntawm lub cev tseem ceeb ntawm cov pwm crucible tuaj yeem tsim kom muaj txoj kab nqes nrog nyias sab saum toj thiab tuab hauv qab, los yog ib qho ncaj cylindrical zoo tsis muaj nqes. Txoj kab nqes feem ntau tswj tau ntawm 1 ~ 4 °, qhov loj ntawm qhov ncaj cylindrical crucible pwm yuav tsum ntau dua los yog sib npaug rau qhov ruaj ntseg thickness ntawm nyias ib feem ntawm lub qhov cub hauv ob sab phlu.

2. Kev txiav txim siab ntawm qhov siab ntawm cov pwm crucible

Nws yog feem ntau ntseeg hais tias qhov ntev ntawm lub crucible pwm los ntawm lub hauv qab ntawm lub cub tawg txheej thickness mus rau qhov loj ntawm lub Upper ib feem ntawm lub cub tawg lub cev. Txawm li cas los xij, cov hauv qab no yuav tsum tau txiav txim siab tag nrho hauv cov txheej txheem tiag tiag: melting efficiency, smelting cov ntaub ntawv, hauv ob sab phlu corrosion ntawm qhov nruab nrab zaus rauv, thiab lub qhov cub npog.

Nyob rau hauv ib txwm muaj xwm txheej, hauv qab ntawm qhov nruab nrab zaus rauv rau kev tsim cov hlau grey lossis cov hlau tsis muaj corroded (kwv yees li 30-50mm), thiab sab sauv ntug ntawm qis tig ntawm induction kauj tuaj yeem nias.

Nyob rau tib lub sijhawm, qhov siab ntawm tag nrho cov pwm crucible yuav tsum yog qhov kev ncua deb ntawm lub dav hlau sab sauv ntawm lub tshuab hluav taws xob hauv qab mus rau qhov siab ntsug ntawm lub cub tawg raws lub dav hlau ntxiv rau qhov siab ntawm li 50mm saum lub cub tawg raws lub dav hlau. Qhov siab no yog qhov tsim nyog rau tag nrho lub cub tawg hlau sintering rauv hauv ob sab phlu, thiab qhov tshwj xeeb qhov siab tsis cuam tshuam rau Kaw lub qhov cub.

3. Qhov loj thiab cov duab ntawm lub ces kaum

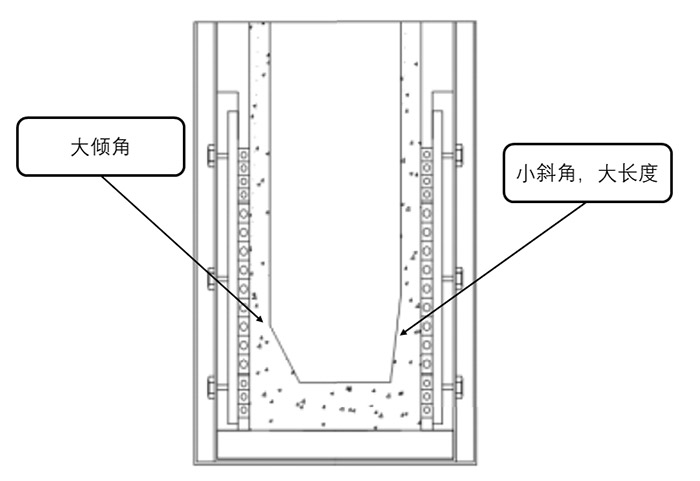

Qhov no yog ib qho yooj yim los tsim; ntxhw ko taw; tsis xws luag, thiab nws yog nyob rau hauv lub hauv ob sab phlu ntawm lub qhov cub rau ib ntev lub sij hawm yuav tsum tau qhwv nyob rau hauv molten hlau thiab tsis tuaj yeem pom, yog li nws yuav tsum tau tsim raws li. Thaum lub inclination lub kaum sab xis loj heev, lub thickness ntawm lub hauv ob sab phlu tuaj yeem nce ntxiv, tab sis nws yog ib qho yooj yim uas yuav ua rau lub hauv ob sab phlu, thiab kev puas tsuaj ntawm cov khoom noj kuj hnyav heev; thiab thaum nws ua raws; lub kaum sab xis me me yog loj; tom qab lub hauv paus ntsiab lus, cov kab tom qab yog ib qho yooj yim rau knot ntawm no. Nws yog compact, thiab muaj peev xwm tiag tiag exert lub hwj chim los ntawm kev tiv thaiv dej, corrosion kuj thiab compression tsis kam ntawm txoj kab nqes ntawm lub qhov cub hauv ob sab phlu thaum lub sij hawm melting txheej txheem, yog li tsis txhob “tso taw” tsis xws luag thiab ua rau cov kev pab cuam lub neej ntawm lub cub tawg hauv ob sab phlu.

4. Laum lub qhov cua thiab cov duab hauv qab

4. Laum lub qhov cua thiab cov duab hauv qab

Pob zeb diamond-zoo li lub qhov yuav tsum tau drilled nyob rau hauv qab, txoj kab nqes thiab sab phab ntsa ntawm lub crucible pwm nyob rau hauv ib tug ncua sij hawm ntawm 200 ~ 300 hli, uas yog conducive mus rau lub paug ntawm noo noo nyob rau hauv lub qhov cub hauv ob sab phlu khoom thaum lub sij hawm ci theem thiab tsub kom qhov kev tiv thaiv, thiab txhim kho cov cua sov thiab ci nyhuv.

The diameter of the hole is preferably 3mm. If it is too small, the exhaust effect will be poor, and if it is too large, it will cause a large amount of lining powder to be ejected from the hole when the furnace is vibrated.

Lub dav hlau hauv qab ntawm cov pwm crucible tsis tuaj yeem rov qab mus rau sab hauv, kab rov tav, los yog protruded txog 1 hli los ntawm qhov chaw, kom tsis txhob muaj qhov sib txawv ntawm huab cua thiab cov txheej txheem kev ntxhov siab nyob rau hauv qab ntawm lub cub tawg tom qab lub cub tawg, uas yuav ua rau “hauv qab. tawg” thaum ci thiab sintering.

5. Tus so

Tag nrho cov welds yuav tsum tau polished smoothly thiab tsis muaj welding hnyav los yog ntse ces kaum raug tso cai; kev kam rau siab thiab concentricity ntawm lub voj voog sab nrauv ntawm cov pwm crucible yuav tsum tswj tsis pub dhau 5 hli; lub crucible pwm yuav tsum tau txhaj blasted ua ntej siv.