- 02

- Aug

Muaj ntau txoj kev quenching feem ntau tam sim no

- 02

- Aug

- 02

- Aug

Ob peb feem ntau quenching txoj kev ntawm tam sim no

Cov txheej txheem quenching 1. Delayed cooling quenching method

Txoj kev quenching feem ntau yog ua ntej txias hauv huab cua, dej kub thiab ntsev da dej kom sov me ntsis siab dua Ar3 lossis Ar1, thiab tom qab ntawd ua ib qho nruab nrab quenching. Txoj kev quenching no feem ntau yog siv rau quenching ntawm qhov chaw nrog cov duab nyuaj thiab qhov chaw nrog cov thickness loj sib txawv thiab xav tau me me deformation.

Cov txheej txheem quenching 2. Cov txheej txheem quenching tus kheej

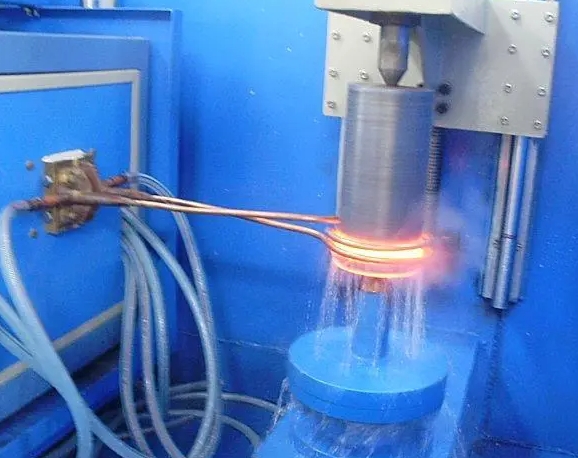

Txoj kev quenching no tsuas yog siv induction hardening qhov chaw kom hloov cov cua sov uas tsis yog tag nrho txias hauv cov tub ntxhais mus rau qhov chaw kom npau taws rau saum npoo. Cov cuab yeej siv los tiv thaiv kev cuam tshuam, xws li chisel, xuas nrig ntaus, rauj, tswj lub sijhawm immersion ntawm qhov yuav tsum tau hardened nyob rau hauv nruab nrab, tshem tawm cov cua txias thaum cov xim ntawm lub unimmersed ib feem pib tig dub, thiab siv cov residual tshav kub. ntawm qhov unimmersed ib feem rau recycle lub immersed ib feem. hluav taws.

Cov txheej txheem quenching 3. Bainite isothermal quenching method

Qhov no quenching txoj kev yog tsuas yog quench lub workpiece mus rau hauv ib da dej nrog lub qis bainite kub ntawm cov hlau nyob rau hauv nruab nrab kub, thiaj li hais tias lub qis bainite transformation tshwm sim. Feem ntau, nws tau khaws cia rau hauv chav da dej rau 30 ~ 60min thiab feem ntau yog siv rau cov hlau alloy, siab carbon steel me me qhov chaw thiab Cov Hlau Hlau Castings.

Cov txheej txheem quenching 4. Ib qho nruab nrab quenching txoj kev

Txoj kev quenching feem ntau yog txias rau hauv lub qhov cub quenching quenching nruab nrab, thiab kev xaiv yog ua raws li cov cua sov hloov coefficient, hardenability, qhov loj me thiab cov duab ntawm cov khoom.

Hom quenching txoj kev 5. Ob chav nruab nrab quenching txoj kev

Txoj kev quenching feem ntau yog thawj zaug muab cov khoom tso rau hauv nruab nrab nrog lub peev xwm txias txias, ua rau lawv quenched, zam “qhov ntswg qhov ntswg” ntawm cov hlau C nkhaus thiab txias rau saum Ms point, thiab tom qab ntawd hloov mus rau qhov nruab nrab tsis muaj zog. ua kom txias ntxiv. Feem ntau siv cov khoom cua txias yog dej-roj, dej-nitrate, dej-cua, roj-cua, thiab lwm yam, lub hom phiaj yog kom tsis txhob deformation thiab tawg. Nws yog siv rau cov duab complex los yog loj workpieces ua los ntawm high carbon steel thiab alloy hlau.

Cov txheej txheem quenching 6. Compound quenching method

Txoj kev quenching no feem ntau yog thawj zaug tua cov khoom ua haujlwm hauv qab Ms kom tau txais martensite nrog ib feem ntawm 10% mus rau 30%, thiab tom qab ntawd isothermal hauv thaj tsam bainite qis. Cov qauv martensite thiab bainite feem ntau yog siv rau hauv cov cuab yeej siv hlau ua haujlwm kom tau txais cov khoom loj hla ntu ua haujlwm, uas tuaj yeem zam thawj hom temper brittleness, txo tus nqi khaws cia austenite thiab nyiam deformation thiab tawg.

Cov txheej txheem quenching 7. Pre-txias isothermal quenching txoj kev

Txoj kev quenching no tsuas yog ua kom txias qhov chaw hauv qhov kub qis (ntau dua Ms) da dej ua ntej, thiab tom qab ntawd hloov mus rau qhov kub siab dua da dej, kom lub austenite undergoes isothermal transformation, uas feem ntau yog siv rau steel qhov chaw nrog qis hardenability.

Cov txheej txheem quenching feem ntau 8. Martensitic graded quenching method hauv qab Ms point

Txoj kev quenching no tsuas yog ua kom lub da dej kub qis dua Ms tab sis siab dua Mf ntawm cov hlau siv rau lub workpiece, lub workpiece yuav txias sai dua hauv chav da dej, thiab cov txiaj ntsig zoo ib yam li qib quenching tseem tuaj yeem tau txais thaum qhov loj me. loj dua. Yog hais tias lub hardenable steel workpiece yog graded thiab ces txias los ntawm dej los yog roj, lub thermal stabilization ntawm austenite yuav txo tau ntxiv, uas yog zoo rau seem stability.

Cov txheej txheem quenching 9. Martensitic graded quenching method

Txoj kev quenching no feem ntau yog rau austenitize cov hlau siv rau qhov chaw, thiab tom qab ntawd muab cov khoom tso rau hauv chav da dej nrog qhov kub thiab txias me ntsis siab dua qhov Ms point ntawm cov hlau rau kev txuag hluav taws xob. Thaum qhov kub ntawm sab hauv thiab sab nraud ntawm qhov chaw yog raws li qhov kub thiab txias ntawm da dej, tshem tawm cov cua txias, thiab hauv cov cua txias, lub supercooling Tensite maj mam hloov mus rau hauv martensite. Nitrate da dej feem ntau yog siv hauv chav da dej, thiab lawv qhov kub yog Ms + (10 ~ 20) ºC. Me me workpieces nrog cov duab complex thiab nruj deformation yuav tsum tau, high-speed steel thiab high-alloy steel cov cuab yeej thiab tuag feem ntau quenched los ntawm txoj kev no.