- 02

- Aug

Ọtụtụ n’ime ụzọ nkwụsị nke a na-ahụkarị ugbu a

- 02

- Aug

- 02

- Aug

Ọtụtụ n’ime ihe a na-ahụkarị usoro nkwụsị ugbu a

Ụzọ ndị na-emenyụ ọkụ na-emekarị 1. Usoro nkwụsị jụrụ oyi na-egbu oge

The quenching usoro bụ tumadi tupu ajụkwa na ikuku, mmiri ọkụ na nnu bat ka okpomọkụ dịtụ elu karịa Ar3 ma ọ bụ Ar1, na mgbe ahụ mee otu-ọkara quenching. A na-etinyekarị usoro nkwụsị nke a na-emenyụ akụkụ ndị nwere ọdịdị dị mgbagwoju anya na akụkụ ndị nwere nnukwu ọdịiche dị oke ma na-achọ obere nrụrụ.

Ụzọ emenyụkarị 2. Ụzọ ndị na-ewe iwe iwe ọkụ

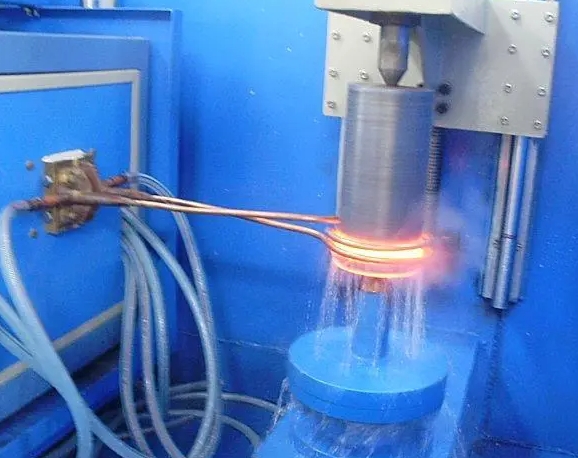

Usoro mmenyụ a na-ejikarị akụkụ induction hardening na-ebufe ọkụ na-adịghị mma kpamkpam n’ime isi gaa n’elu iji kpasuo elu. Ngwa ndị a na-eji eguzogide mmetụta, dị ka chisel, ntụmadị, hama, na-achịkwa oge imi mmiri nke akụkụ a ga-esi sie ike na ọkara, wepụ ikuku jụrụ oyi mgbe agba nke akụkụ ahụ na-emikpughị amalite ịgba oji, ma jiri okpomọkụ fọdụrụnụ. nke akụkụ a na-emikpughị iji megharịa akụkụ nke imikpu. ọkụ.

Ụzọ emenyụkarị 3. Bainite isothermal quenching method

Usoro a na-emenyụ ọkụ bụ iji menyụọ workpiece n’ime bath nke nwere obere bainite okpomọkụ nke ígwè na etiti okpomọkụ, nke mere na mgbanwe bainite dị ala na-eme. N’ozuzu, a na-edebe ya na bat maka 30 ~ 60min ma na-ejikarị ya eme ihe maka ígwè alloy, nnukwu carbon ígwè obere akụkụ na nkedo ígwè Ductile.

Ụzọ nkwụsị nke nkịtị 4. Usoro nkwụsị nke otu

The quenching usoro bụ tumadi jụrụ na a quenching ọkụ quenching ọkara, na nhọrọ na-mere dị ka okpomọkụ nyefe ọnụọgụ, hardenability, size na udi nke akụkụ.

Ụzọ emenyụkarị 5. Ụzọ nkwụsị nke ọkara okpukpu abụọ

The quenching usoro bụ tumadi na-akpa na-etinye akụkụ n’ime a na-ajụ na ike jụrụ ike, mee ka ha menyụọ, zere “n’ọnụ imi” nke ígwè C curve na jụụ n’elu Ms point, na mgbe ahụ ngwa ngwa nyefee na-adịghị ike ọkara ka. nọgide na-ajụ oyi. Usoro mgbasa ozi jụrụ oyi nke a na-ejikarị bụ mmiri-mmanụ, mmiri-nitrate, mmiri-ikuku, mmanụ-ikuku, wdg, nzube ya bụ iji zere nrụrụ na mgbawa. Ọ na-eji maka mgbagwoju shapes ma ọ bụ nnukwu workpieces mere nke elu carbon ígwè na alloy ígwè.

Ụzọ emenyụkarị 6. Ụzọ nkwụsị nke ngwakọta

Usoro nkwụsị a bụ nke mbụ ị ga-emenyụ workpiece ruo n’okpuru Nwada iji nweta martensite nwere obere olu nke 10% ruo 30%, wee mee isothermal na mpaghara bainite dị ala. A na-ejikarị ihe owuwu martensite na bainite mee ihe na ihe eji eme ihe na-arụ ọrụ na-arụ ọrụ na-arụ ọrụ iji nweta nnukwu akụkụ cross-section workpieces, nke nwere ike izere ụdị mbụ nke iwe ọkụ, belata ọnụ ọgụgụ nke austenite na-ejide ya na ọchịchọ nke deformation na cracking.

Ụzọ nkwụsị nke nkịtị 7. Tupu-ajụ oyi isothermal quenching ụzọ

Nke a na usoro quenching bụ tumadi na-ajụkwa akụkụ na a ala okpomọkụ (dị ukwuu karịa Ms) bath mbụ, na mgbe ahụ nyefee ha na a elu okpomọkụ bath, nke mere na austenite undergae isothermal mgbanwe, nke a na-ejikarị maka ígwè akụkụ na ala hardening.

Ụzọ ndị na-emenyụ ọkụ 8. Ụzọ nkwụsị nke Martensitic n’okpuru isi okwu

Nke a quenching usoro bụ tumadi ime ka bat okpomọkụ ala karịa Nwada ma elu karịa Mf nke ígwè eji maka workpiece, na workpiece ga-mma ngwa ngwa na bath, na otu N’ihi dị ka graded quenching ka nwere ike nweta mgbe size bụ. ibu. Ọ bụrụ na a na-eme ka ihe na-arụ ọrụ nchara na-esi ike ma mee ka mmiri ma ọ bụ mmanụ mee ka ọ dị jụụ, a ga-ebelata nkwụsịtụ nke austenite, nke bara uru na nkwụsi ike akụkụ.

Ụzọ emenyụkarị 9. Martensitic graded quenching methods

Usoro a na-emenyụ ọkụ bụ ịgbanye nchara a na-eji maka akụkụ ahụ, wee mikpuo akụkụ ahụ n’ime bat nke nwere okpomọkụ dị elu karịa ebe Ms nke ígwè ahụ maka nchekwa ọkụ. Mgbe okpomọkụ dị n’ime na n’èzí nke akụkụ ahụ kwekọrọ na okpomọkụ bat ahụ, wepụ ikuku jụrụ oyi, na ikuku dị jụụ, Supercooling Tensite ji nwayọọ nwayọọ ghọọ martensite. A na-ejikarị bath nitrate eme ihe na bath okpomọkụ, na okpomọkụ ha bụ Ms+(10 ~ 20)ºC. Obere workpieces na mgbagwoju shapes na siri deformation chọrọ, elu-ọsọ ígwè na elu-alloy ígwè ngwá ọrụ na anwụ na-emekarị emenyụ site a usoro.