- 02

- Aug

Zambiri mwa njira zozimitsira zodziwika kwambiri masiku ano

- 02

- Aug

- 02

- Aug

Ambiri ambiri njira zochepetsera thupi pakadali pano

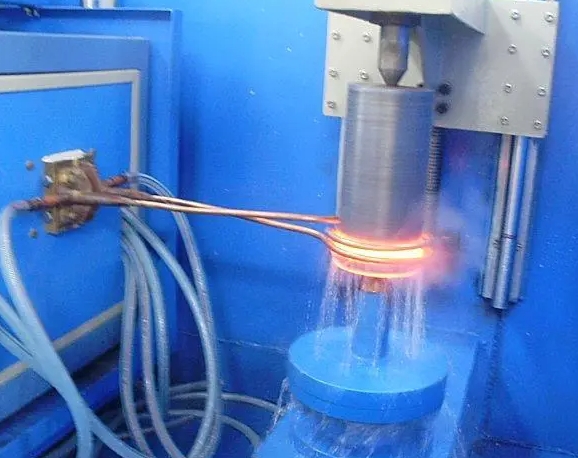

Njira zozimitsira wamba 1. Kuzengereza kuzimitsa njira yozimitsa

Njira yozimitsira ndiyo makamaka kuziziritsa mumpweya, madzi otentha ndi kusamba kwa mchere kutentha pang’ono kuposa Ar3 kapena Ar1, ndiyeno kuchita quenching imodzi yapakatikati. Njira yozimitsa iyi nthawi zambiri imagwiritsidwa ntchito pozimitsa magawo omwe ali ndi mawonekedwe ovuta komanso magawo omwe ali ndi kusiyana kwakukulu kwa makulidwe ndipo amafuna kupunduka kochepa.

Njira zozimitsira wamba 2. Njira zozimitsa zokha

Njira yozimitsira iyi makamaka imagwiritsa ntchito zida zowumitsa zowotchera kusamutsa kutentha komwe sikunaziziretu m’kati kupita kumtunda kuti kutenthetse pamwamba. Zida zomwe zimagwiritsidwa ntchito polimbana ndi mphamvu, monga chisel, nkhonya, nyundo, kuwongolera nthawi yomiza ya gawo kuti liwumitsidwe pakati, kutulutsa mpweya woziziritsa pamene mtundu wa gawo losamizidwa uyamba kukhala wakuda, ndikugwiritsa ntchito kutentha kotsalira. wa gawo losamizidwa kuti agwiritsenso ntchito gawo lomizidwa. moto.

Njira zozimitsira wamba 3. Njira yozimitsa ya bainite isothermal

Njira yozimitsira iyi makamaka ndikuzimitsa chogwiritsira ntchito mu bafa ndi kutentha kwapansi kwa chitsulo pa kutentha kwapakati, kotero kuti kusinthika kwapansi kwa bainite kumachitika. Nthawi zambiri, imasungidwa mubafa kwa 30 ~ 60min ndipo nthawi zambiri imagwiritsidwa ntchito ngati chitsulo cha aloyi, zitsulo zam’mwamba za carbon zitsulo zazing’onoting’ono ndi ma Ductile iron castings.

Njira zozimitsira wamba 4. Njira imodzi yozimitsa sing’anga imodzi

Njira yozimitsa imakhala yozizira kwambiri m’ng’anjo yozimitsa ng’anjo yozimitsa, ndipo kusankha kumapangidwa molingana ndi kutentha kwa kutentha, kuuma, kukula ndi mawonekedwe a zigawozo.

Njira zozimitsira wamba 5. Njira yozimitsira pawiri yapakatikati

Njira yozimitsira ndikuyamba kuyika zigawozo mu sing’anga yokhala ndi mphamvu yoziziritsa yamphamvu, kuzipangitsa kuzimitsidwa, kupewa “nsonga ya mphuno” ya chitsulo chopindika cha C ndi kuziziritsa pamwamba pa Ms point, kenako mwachangu kupita kumalo ofooka. pitirizani kuziziritsa. Zomwe zimagwiritsidwa ntchito nthawi zambiri zimakhala ndi mafuta-mafuta, madzi-nitrate, mpweya wamadzi, mpweya wamafuta, ndi zina zotero, zomwe cholinga chake ndikupewa kupunduka ndi kusweka. Amagwiritsidwa ntchito ngati mawonekedwe ovuta kapena zazikulu zopangira zida zopangidwa ndi chitsulo cha carbon ndi alloy steel.

Njira zozimitsira wamba 6. Njira zozimitsira pagulu

Njira yozimitsa iyi ndiyoyamba kuyimitsa chogwirira ntchito mpaka pansi pa Ms kuti mupeze martensite ndi gawo la 10% mpaka 30%, kenako ndi isothermal m’chigawo chotsika cha bainite. The martensite ndi bainite nyumba nthawi zambiri ntchito aloyi chida zitsulo workpieces kupeza lalikulu mtanda gawo workpieces, amene angapewe mtundu woyamba wa kupsa mtima brittleness, kuchepetsa kuchuluka anasungidwa austenite ndi chizolowezi mapindikidwe ndi ang’onoang’ono.

Njira zozimitsira wamba 7. Njira zozimitsa zoziziritsa kuzizira za isothermal

Izi quenching njira makamaka kuziziritsa mbali mu kutentha m’munsi (wamkulu kuposa Ms) kusamba choyamba, ndiyeno kusamutsa iwo apamwamba kutentha kusamba, kuti austenite akukumana isothermal kusintha, amene nthawi zambiri ntchito mbali zitsulo ndi m’munsi hardenability.

Common quenching njira 8. Martensitic graded quenching njira pansipa Ms mfundo

Njira yozimitsira iyi makamaka imapangitsa kuti kutentha kwa kusamba kukhale kochepa kuposa Ms koma kupitirira kuposa Mf zitsulo zomwe zimagwiritsidwa ntchito pa workpiece, workpiece idzakhala itakhazikika mofulumira mu kusamba, ndipo zotsatira zomwezo monga kuzimitsa graded zitha kupezekabe pamene kukula kuli. chokulirapo. Ngati chitsulo cholimba chachitsulo chimayikidwa ndikukhazikika ndi madzi kapena mafuta, kukhazikika kwa kutentha kwa austenite kumatha kuchepetsedwa, komwe kumapindulitsa kukhazikika kwazithunzi.

Njira zozimitsira wamba 9. Njira zozimitsa za Martensitic graded

Njira yozimitsira imeneyi makamaka ndiyo kulimbitsa zitsulo zomwe zimagwiritsidwa ntchito pazigawo, ndiyeno kumiza ziwalozo mu bafa ndi kutentha kwapamwamba pang’ono kuposa Ms point yachitsulo pofuna kuteteza kutentha. Pamene kutentha kwa mkati ndi kunja kwa zigawozo kumagwirizana ndi kutentha kwa kusamba, chotsani kuziziritsa kwa mpweya, ndipo mu mpweya wozizira, supercooling Tensite imasintha pang’onopang’ono kukhala martensite. Masamba a nitrate amagwiritsidwa ntchito kwambiri m’malo otentha, ndipo kutentha kwake ndi Ms+(10 ~ 20)ºC. Zopangira zing’onozing’ono zokhala ndi mawonekedwe ovuta komanso zofunikira zowonongeka, zitsulo zothamanga kwambiri komanso zida zachitsulo zachitsulo ndi kufa nthawi zambiri zimazimitsidwa ndi njirayi.