- 02

- Aug

Dzakawanda dzenzira dzakajairika dzekudzima pari zvino

- 02

- Aug

- 02

- Aug

Several of the most common nzira dzekudzima parizvino

Common quenching nzira 1. Kunonoka kutonhora kudzima nzira

Iyo nzira yekudzima ndeye pre-inotonhorera mumhepo, mvura inopisa uye kugeza munyu kune tembiricha yakakwira zvishoma pane Ar3 kana Ar1, uyezve kuita imwe-yepakati quenching. Iyi nzira yekudzima inowanzo shandiswa pakudzima zvidimbu zvine maumbirwo akaomarara uye zvikamu zvine makukutu makuru akasiyana uye zvinoda deformation diki.

Common quenching nzira 2. Self-tempering quenching nzira

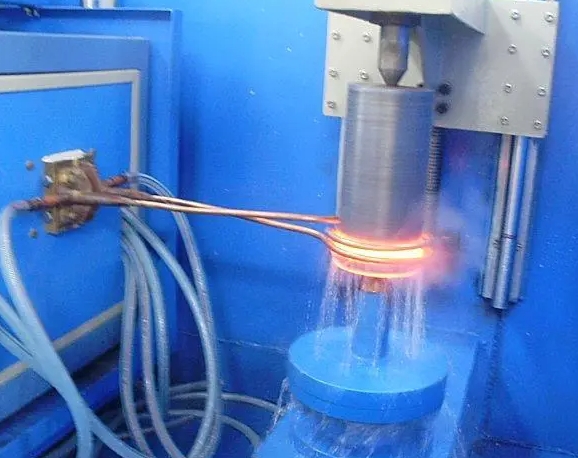

This quenching method mainly uses induction hardening parts to transfer the heat that is not completely cooled in the core to the surface to temper the surface. Tools used to withstand impact, such as chisel, punch, hammer, control the immersion time of the part to be hardened in the medium, take out the air cooling when the color of the unimmersed part starts to turn black, and use the residual heat of the unimmersed part to recycle the immersed part. fire.

Common quenching nzira 3. Bainite isothermal quenching nzira

Iyi nzira yekudzima inonyanya kudzima iyo workpiece mubhati ine yakaderera bainite tembiricha yesimbi pane yepakati tembiricha, kuitira kuti yakaderera bainite shanduko inoitika. Kazhinji, inochengetwa mubhavhu kwe30 ~ 60min uye inowanzoshandiswa kune alloy simbi, yakakwira kabhoni simbi diki-saizi zvikamu uye Ductile iron castings.

Common quenching nzira 4. Single medium quenching nzira

Iyo yekudzima nzira inonyanya kutonhora muchoto chekudzima moto wepakati, uye kusarudzwa kunoitwa zvinoenderana nekupisa kwekutamisa coefficient, kuoma, ukuru uye chimiro chezvikamu.

Common quenching nzira 5. Double medium quenching nzira

Iyo nzira yekudzima ndeyekutanga kuisa zvikamu mukati mepakati nekukwanisa kutonhora kwakasimba, kuita kuti zvidzime, kudzivirira “mhino yemhino” yesimbi C curve uye inotonhorera kumusoro kweMs point, uye nekukurumidza kuendesa kune isina kusimba svikiro kusvika. ramba uchitonhora. Inowanzo shandiswa kutonhora midhiya ndeyemvura-mafuta, mvura-nitrate, mvura-mhepo, mafuta-mhepo, nezvimwewo, chinangwa chekudzivisa deformation uye kuputika. Iyo inoshandiswa kune yakaoma maumbirwo kana mahombe workpiece akagadzirwa nepamusoro kabhoni simbi uye alloy simbi.

Common quenching methods 6. Compound quenching methods

Iyi nzira yekudzima ndeyekutanga kudzima workpiece kusvika pazasi Ms kuwana martensite ine vhoriyamu chikamu che10% kusvika 30%, uyezve isothermal munzvimbo yepasi bainite. Iyo martensite uye bainite zvimiro zvinowanzo shandiswa mune alloy chishandiso simbi workpieces kuwana hombe-chikamu-chikamu workpieces, izvo zvinogona kudzivirira yekutanga mhando yehasha brittleness, kuderedza kuwanda kwekuchengetwa austenite uye tsika ye deformation uye kuputika.

Nzira dzekudzima dzakajairika 7. Pre-kutonhora isothermal quenching nzira

This quenching method is mainly to cool the parts in a lower temperature (greater than Ms) bath first, and then transfer them to a higher temperature bath, so that the austenite undergoes isothermal transformation, which is often used for steel parts with lower hardenability.

Common quenching nzira 8. Martensitic graded quenching nzira pazasi Ms point

This quenching method is mainly to make the bath temperature lower than Ms but higher than Mf of the steel used for the workpiece, the workpiece will be cooled faster in the bath, and the same result as graded quenching can still be obtained when the size is larger. If the hardenable steel workpiece is graded and then cooled by water or oil, the thermal stabilization of austenite can be further reduced, which is beneficial to dimensional stability.

Common quenching methods 9. Martensitic graded quenching methods

Iyi nzira yekudzima ndeye austenitize simbi inoshandiswa kune zvikamu, uyezve kunyudza zvikamu mubhavhu ine tembiricha yakakwira zvishoma pane iyo Ms point yesimbi yekuchengetedza kupisa. Kana kutonhora kwemukati nekunze kwezvikamu kuchienderana nekushisa kwekugezera, tora kunze kwemhepo inotonhorera, uye mumhepo inotonhorera, iyo supercooling Tensite inoshandura zvishoma nezvishoma kuita martensite. Mabhati eNitrate anowanzo shandiswa mumabhavhu ekupisa, uye tembiricha yawo iMs+(10~20)ºC. Zvidiki zvekushanda zvine maumbirwo akaomarara uye zvakaomesesa deformation zvinodiwa, yakakwirira-kumhanya simbi uye yakakwira-alloy simbi maturusi uye anofa kazhinji anodzimwa neiyi nzira.