- 02

- Aug

Several of the most common quenching methods at present

- 02

- Aug

- 02

- Aug

Several of the most common quenching methods ayeuna

Common quenching methods 1. Delayed cooling quenching method

The quenching method is mainly to pre-cool in air, hot water and salt bath to a temperature slightly higher than Ar3 or Ar1, and then perform single-medium quenching. This quenching method is usually applied to the quenching of parts with complex shapes and parts with large thickness disparities and requiring small deformation.

Common quenching methods 2. Self-tempering quenching methods

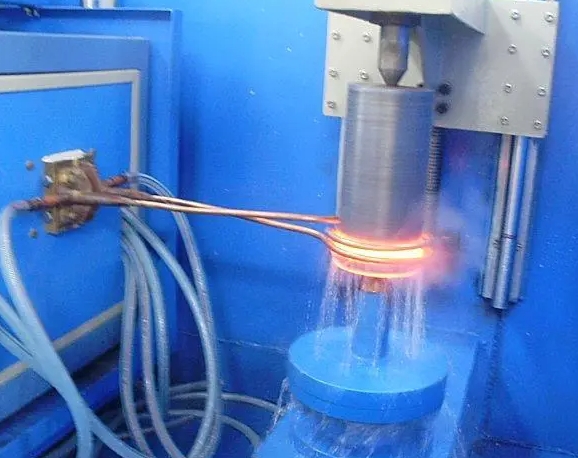

This quenching method mainly uses induction hardening parts to transfer the heat that is not completely cooled in the core to the surface to temper the surface. Tools used to withstand impact, such as chisel, punch, hammer, control the immersion time of the part to be hardened in the medium, take out the air cooling when the color of the unimmersed part starts to turn black, and use the residual heat of the unimmersed part to recycle the immersed part. fire.

Common quenching methods 3. Bainite isothermal quenching method

This quenching method is mainly to quench the workpiece into a bath with the lower bainite temperature of the steel at an intermediate temperature, so that the lower bainite transformation occurs. Generally, it is kept in the bath for 30~60min and is often used for alloy steel, high carbon steel small-sized parts and Ductile iron castings.

Common quenching methods 4. Single medium quenching method

The quenching method is mainly cooling in a quenching furnace quenching medium, and the selection is made according to the heat transfer coefficient, hardenability, size and shape of the parts.

Common quenching methods 5. Double medium quenching method

The quenching method is mainly to first put the parts into a medium with strong cooling ability, make them quenched, avoid the “nose tip” of the steel C curve and cool to above the Ms point, and then quickly transfer to a weak medium to continue cooling. Commonly used cooling media are water-oil, water-nitrate, water-air, oil-air, etc., the purpose of which is to avoid deformation and cracking. It is used for complex shapes or large workpieces made of high carbon steel and alloy steel.

Common quenching methods 6. Compound quenching methods

This quenching method is mainly to first quench the workpiece to below Ms to obtain martensite with a volume fraction of 10% to 30%, and then isothermal in the lower bainite region. The martensite and bainite structures are often used in alloy tool steel workpieces to obtain large cross-section workpieces, which can avoid the first type of temper brittleness, reduce the amount of retained austenite and the tendency of deformation and cracking.

Common quenching methods 7. Pre-cooling isothermal quenching methods

This quenching method is mainly to cool the parts in a lower temperature (greater than Ms) bath first, and then transfer them to a higher temperature bath, so that the austenite undergoes isothermal transformation, which is often used for steel parts with lower hardenability.

Common quenching methods 8. Martensitic graded quenching methods below Ms point

This quenching method is mainly to make the bath temperature lower than Ms but higher than Mf of the steel used for the workpiece, the workpiece will be cooled faster in the bath, and the same result as graded quenching can still be obtained when the size is larger. If the hardenable steel workpiece is graded and then cooled by water or oil, the thermal stabilization of austenite can be further reduced, which is beneficial to dimensional stability.

Common quenching methods 9. Martensitic graded quenching methods

This quenching method is mainly to austenitize the steel used for the parts, and then immerse the parts in a bath with a temperature slightly higher than the Ms point of the steel for heat preservation. When the temperature of the inside and outside of the parts is consistent with the bath temperature, take out the air cooling, and in the air cooling, the supercooling Tensite slowly transforms into martensite. Nitrate baths are commonly used in thermal baths, and their temperature is Ms+(10~20)ºC. Small workpieces with complex shapes and strict deformation requirements, high-speed steel and high-alloy steel tools and dies are often quenched by this method.