- 02

- Aug

Uninzi lweendlela ezixhaphakileyo zokucima okwangoku

- 02

- Aug

- 02

- Aug

Uninzi lwezona ziqhelekileyo iindlela zokucoca ngoku

Iindlela eziqhelekileyo zokucima 1. Indlela yokucima ukupholisa ilibazisekile

Indlela yokucima ikakhulu ukupholisa kwangaphambili emoyeni, amanzi ashushu kunye nebhafu yetyuwa ukuya kumaqondo obushushu angaphezulu kancinci kune-Ar3 okanye i-Ar1, kwaye emva koko enze ukucinywa okuphakathi. Le ndlela yokucima idla ngokusetyenziswa ekucinyweni kwamalungu anemilo entsonkothileyo kunye neenxalenye ezinobunzima obukhulu kwaye zifuna i-deformation encinci.

Iindlela eziqhelekileyo zokucima 2. Iindlela zokuzicima ukuzicima

Le ndlela yokucima ubukhulu becala isebenzisa iinxalenye zokwenziwa lukhuni ukudlulisa ubushushu obungapholiswanga ngokupheleleyo kumbindi ukuya kumphezulu ukuqumbisa umphezulu. Izixhobo ezisetyenziselwa ukumelana neempembelelo, ezifana netshiseli, ipunch, ihamile, ukulawula ixesha lokuntywiliselwa kwenxalenye ukuze iqiniswe phakathi, khupha umoya opholileyo xa umbala wenxalenye engatshoniyo uqala ukuba mnyama, kwaye usebenzise ubushushu obushiyekileyo. yenxalenye engantywiliselwanga ukurisayikilisha indawo entywilisiweyo. umlilo.

Iindlela eziqhelekileyo zokucima 3. Indlela yokucima i-Bainite isothermal

Le ndlela yokucima ubukhulu becala kukucima i-workpiece kwindawo yokuhlambela kunye neqondo eliphantsi le-bainite yentsimbi kwiqondo lokushisa eliphakathi, ukwenzela ukuba ukuguqulwa kwe-bainite ephantsi kwenzeke. Ngokuqhelekileyo, igcinwa kwindawo yokuhlambela i-30 ~ 60min kwaye isoloko isetyenziselwa i-alloy steel, i-carbon steel high-size iinxalenye ezincinci kunye ne-Ductile iron castings.

Iindlela eziqhelekileyo zokucima 4. Indlela yokucima enye ephakathi

Indlela yokucima ngokuyininzi ipholisa kwindawo yokucima isithando somlilo, kwaye ukhetho lwenziwa ngokwe-coefficient yokudlulisa ukushisa, ukuqina, ubungakanani kunye nokuma kwamacandelo.

Iindlela eziqhelekileyo zokucima 5. Indlela yokucima kabini ephakathi

Indlela yokucima ubukhulu becala kukuqala ukubeka iinxalenye kwindawo ephakathi ngesakhono esinamandla sokupholisa, ukubenza bacime, banqande “incam yempumlo” yentsimbi ye-C curve kwaye ipholile ukuya ngasentla kwe-Ms point, kwaye ngokukhawuleza idlulisele kwindawo ebuthathaka ukuya. qhubeka nokupholisa. Amajelo okupholisa asetyenziswa ngokuqhelekileyo ngamanzi-oyile, i-nitrate yamanzi, umoya-manzi, i-oyile-moya, njl., injongo yokuphepha ukuguqulwa kunye nokuqhekeka. Isetyenziselwa iimilo eziyinkimbinkimbi okanye ii-workpieces ezinkulu ezenziwe nge-carbon steel high kunye ne-alloy steel.

Iindlela eziqhelekileyo zokucima 6. Iindlela zokucima umdibaniso

Le ndlela yokucima ubukhulu becala kukuqala ukucima i-workpiece ukuya ngaphantsi kukaNks ukufumana i-martensite kunye neqhezu lomthamo we-10% ukuya kuma-30%, kwaye emva koko isothermal kwingingqi ye-bainite ephantsi. Izakhiwo ze-martensite kunye ne-bainite zihlala zisetyenziselwa i-alloy tool workpieces zensimbi ukuze zifumane i-workpieces enkulu ye-cross-section, enokuthi iphephe uhlobo lokuqala lwe-tender brittleness, ukunciphisa inani le-austenite egciniweyo kunye nokuthambekela kwe-deformation kunye nokuqhekeka.

Iindlela eziqhelekileyo zokucima 7. Iindlela zokucinywa kwe-isothermal kwangaphambili

Le ndlela yokucima ubukhulu becala ukupholisa amacandelo kwiqondo lobushushu elisezantsi (omkhulu kuno Ms) ukuhlamba kuqala, uze udlulisele kwibhafu yobushushu obuphezulu, ukuze i-austenite idlule kwinguqu ye-isothermal, edla ngokusetyenziswa kwiindawo zentsimbi ezinobunzima obuphantsi.

Iindlela eziqhelekileyo zokucima 8. Iindlela zokucinywa ze-Martensitic graded ngezantsi kwe-Ms point

Le ndlela yokucima ubukhulu becala kukwenza ubushushu bokuhlamba bube sezantsi kunoNksk kodwa buphezulu kuneMf yentsimbi esetyenziselwa iworkpiece, i-workpiece iya kupholiswa ngokukhawuleza ebhafini, kwaye umphumo ofanayo njengoko ucinywa ngokwemigangatho usenakho ukufumaneka xa ubungakanani. inkulu. Ukuba i-workpiece yensimbi enzima ihlelwa kwaye ipholile ngamanzi okanye ioli, ukuzinza kwe-thermal ye-austenite kunokunciphisa ngakumbi, okunenzuzo ekuzinzeni kwe-dimensional.

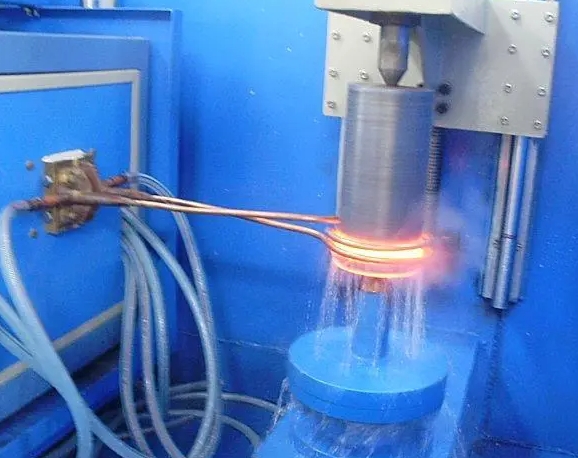

Iindlela eziqhelekileyo zokucima 9. Iindlela zokucinywa ze-Martensitic graded

Le ndlela yokucima ubukhulu becala kukuba i-austenitize intsimbi esetyenziselwa iindawo, kwaye emva koko untywilisele iinxalenye kwindawo yokuhlambela ngeqondo lobushushu elingaphezulu kancinane kune-Ms point yentsimbi yokugcina ubushushu. Xa ubushushu bangaphakathi nangaphandle kweendawo buhambelana nobushushu bokuhlamba, khupha umoya opholileyo, kwaye emoyeni opholileyo, i-supercooling Tensite iguquka ngokukhawuleza ibe yi-martensite. Iibhafu zeNitrate ziqhele ukusetyenziswa kwiibhafu ezishushu, kwaye ubushushu bazo nguMs+(10~20)ºC. Izixhobo zokusebenza ezincinci ezinemilo enzima kunye neemfuno ezingqongqo zokuguqulwa, isinyithi esinesantya esiphezulu kunye nezixhobo zetsimbi eziphezulu kunye neefa zihlala zicinywa ngale ndlela.