- 15

- Feb

Technical requirements for the crucible mold of the induction melting furnace

Technical requirements for the crucible mold of the induction melting furnace

The nkhungu crucible ayenera kukhala ndi mphamvu zokwanira pa ntchito yomanga ndi sintering ndondomeko, ndipo siyenera kupunduka pa ntchito yomanga kuonetsetsa kuti akhoza kupatsira mphamvu kugwedera kwa akalowa zinthu kuti yaying’ono akalowa zinthu. Kutentha pamwamba pa akalowa zinthu ayenera kukhala mu sintering ndondomeko. Sichidzasungunuka chisanapangidwe, ndipo sichidzawonongeka kwanuko kapena kusungunuka ndi mphamvu ya maginito.

Once the above situation occurs, it will cause the lining material to be filled into the void formed by the deformation of the mold, resulting in a decrease in the density of the lining, thereby affecting the strength of the lining and shortening the life of the lining.

According to practical experience, the 6-ton furnace crucible mold uses an electric vibrator to shake the original 6mm steel plate crucible mold to 10mm in real time, and the 20-ton induction melting furnace crucible mold uses 10mm thick A3 steel plate welding to ensure that the crucible mold has strong strength , The vibrator is not easy to deform during the hammering and beating process, and the vibration energy can be transferred to the furnace lining material through the crucible mold to achieve the purpose of compacting the furnace lining, thereby ensuring the strength of the furnace lining and ensuring the service life of the furnace lining.

The structural characteristics of the crucible mold have a direct impact on the life of the furnace lining, so pay attention to the following aspects:

1. The circumference of the main body of the crucible mold

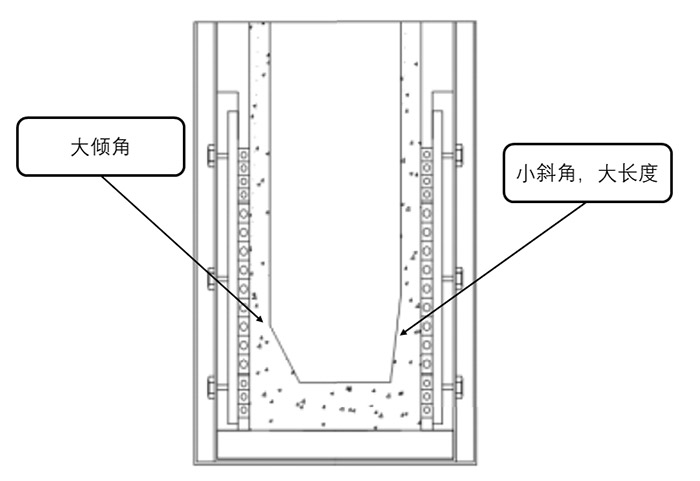

The circumference of the main body of the crucible mold can be designed to have a slope with a thin top and a thick bottom, or a straight cylindrical shape without slope. The slope is generally controlled at 1~4°, the size of the straight cylindrical crucible mold should be greater than or equal to the safe thickness of the thin part of the furnace lining.

2. Kutsimikiza kwa kutalika kwa nkhungu ya crucible

Ambiri amakhulupirira kuti kutalika kwa nkhungu crucible kuchokera pansi pa ng’anjo akalowa makulidwe kukula kwa kumtunda kwa ng’anjo thupi. Komabe, zinthu zotsatirazi ziyenera kuganiziridwa bwino pazochitika zenizeni: kusungunula bwino, kusungunula zipangizo, zigawo zowonongeka za ng’anjo yapakati, ndi chivundikiro cha ng’anjo.

Nthawi zonse, pansi pa ng’anjo yapakatikati yopangira chitsulo chotuwira kapena chitsulo chodulira sichimawonongeka kwambiri (pafupifupi 30-50mm), ndipo m’mphepete chakumtunda kwa koyilo yolowera kumunsi imatha kukanikizidwa.

At the same time, the height of the entire crucible mold should be the distance from the upper plane of the furnace bottom lining to the vertical height of the furnace along the plane plus the height of about 50mm above the furnace along the plane. This height is conducive to the full furnace iron sintering furnace lining, and the specific height does not affect Close the furnace lid.

3. Kukula ndi mawonekedwe a ngodya

Izi ndizosavuta kupanga; mapazi a njovu; zolakwika, ndipo ili pansi pa ng’anjo ya ng’anjo kwa nthawi yayitali kuti ikulungidwe muchitsulo chosungunula ndipo sichingawonekere, choncho iyenera kupangidwa moyenerera. Pamene mbali yokhotakhotayo ndi yaikulu kwambiri, makulidwe a kansalu amatha kuwonjezereka, koma n’zosavuta kupangitsa kuti mzere ukhale wophimbidwa, ndipo kuwonongeka kwa makina kudyetsa kumakhala koopsa; ndipo ikadzatsatiridwa; ngodya yaying’ono ya bevel ndi yayikulu; pambuyo mfundo, akalowa kenako n’zosavuta mfundo pano. Ndizophatikizana, ndipo zimatha kukhala ndi zotsatira zamphamvu zotsutsana ndi kupopera, kukana kwa dzimbiri komanso kukana kukanikiza pamtunda wa ng’anjo ya ng’anjo panthawi yosungunuka, potero kupewa zolakwika za “mapazi a njovu” ndikuwonjezera moyo wautumiki wa ng’anjo yamoto.

4. Boolani dzenje lotulukira ndi pansi

4. Boolani dzenje lotulukira ndi pansi

Mabowo ooneka ngati diamondi ayenera kubowola pansi, otsetsereka ndi makoma a mbali ya nkhungu crucible pakadutsa 200 ~ 300mm, amene amathandiza kutulutsa chinyezi mu ng’anjo akalowa zinthu pa siteji kuphika ndi kumawonjezera kukana, ndi kumawonjezera Kutentha ndi Kuphika.

The diameter of the hole is preferably 3mm. If it is too small, the exhaust effect will be poor, and if it is too large, it will cause a large amount of lining powder to be ejected from the hole when the furnace is vibrated.

Ndege yapansi ya nkhungu yowotcherayo siyingakhazikikenso mkati, yopingasa, kapena kutulutsa pafupifupi 1mm kuchokera pakati, kuti mupewe kusiyana kwa mpweya komanso kupsinjika kwamapangidwe pansi pa ng’anjoyo ikamanga ng’anjo, zomwe zingayambitse “pansi”. kuphulika” panthawi yophika ndi kuphika.

5. The rest

All welds must be polished smoothly and no welding solvent or sharp corners are allowed; the tolerance and concentricity of the outer circle of the crucible mold should be controlled within 5mm; the crucible mold must be shot blasted before use.