- 15

- Feb

Iimfuno zobuchwephesha kwi-crucible mold yesithando sokunyibilikisa i-induction

Iimfuno zobuchwephesha kwi-crucible mold yesithando sokunyibilikisa i-induction

I-crucible mold kufuneka ibe namandla okwaneleyo ngexesha lokwakhiwa kunye nenkqubo ye-sintering, kwaye akufanele ikhubazeke ngexesha lenkqubo yokwakha ukuze kuqinisekiswe ukuba inokudlulisa amandla okugubha kwi-lining material ukuze idibanise i-lining material. Umphezulu oshushu wezinto zokugqoka kufuneka ube kwinkqubo ye-sintering. Ayiyi kunyibilika ngaphambi kokubunjwa, kwaye ayiyi kuphazamiseka kwindawo okanye inyibilike ngenxa yempembelelo yamagnetic field.

Nje ukuba le meko ingentla yenzekile, iya kubangela ukuba izinto zelinen zizaliswe kwi-void eyenziwe yi-deformation ye-mold, ekhokelela ekunciphiseni koxinano lwe-lining, ngaloo ndlela ichaphazela amandla ombane kunye nokunciphisa ubomi bomgca. umgca.

Ngokwamava asebenzayo, i-6-toni ye-6-toni ye-oven crucible mold isebenzisa i-vibrator yombane ukugubha i-original 10mm ipleyiti yentsimbi ye-crucible mold ukuya kwi-20mm ngexesha lokwenyani, kunye ne-10-toni ye-3-toni yokunyibilikisa i-mold crucible mold isebenzisa i-XNUMXmm engqindilili ye-AXNUMX yentsimbi ye-welding ukuqinisekisa ukuba i-mold crucible inamandla anamandla , I-vibrator ayilula ukukhubaza ngexesha le-hammering kunye nenkqubo yokubetha, kwaye amandla okungcangcazela angakwazi ukudluliselwa kwizinto eziphathekayo zomlilo ngokusebenzisa i-mold crucible ukufezekisa injongo yokudibanisa i-furnace lining, ngaloo ndlela iqinisekisa. amandla ombane wesithando somlilo kunye nokuqinisekisa ubomi benkonzo yesithando somlilo.

Iimpawu zesakhiwo se-crucible mold inefuthe elithe ngqo kubomi bomgca wesithando somlilo, ngoko ke qwa lasela le miba ilandelayo:

1. Umjikelezo womzimba oyintloko we-crucible mold

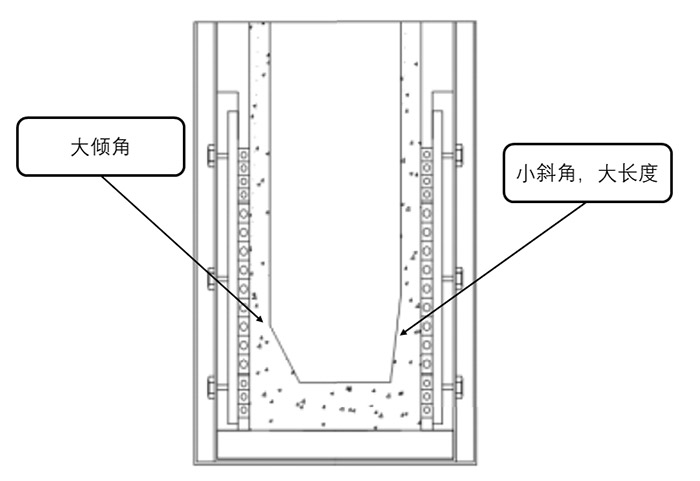

Umjikelezo womzimba oyintloko we-crucible mold unokuyilwa ukuba ube ne-slope kunye nomphezulu obhityileyo kunye nomgangatho ophantsi, okanye i-cylindrical shape straight ngaphandle kwe-slope. I-slope ilawulwa ngokubanzi kwi-1 ~ 4 °, ubukhulu be-mold cylindrical crucible crucible kufuneka ibe mkhulu okanye ilingane nobukhulu obukhuselekileyo becala elincinci le-lining yesithando somlilo.

2. Ukuzimisela ukuphakama kwesikhunta se-crucible

Ngokuqhelekileyo kukholelwa ukuba ubude be-crucible mold ukusuka ezantsi kwe-furnace lining ubukhulu ukuya kubukhulu becala eliphezulu lomzimba wesithando somlilo. Nangona kunjalo, ezi zinto zilandelayo kufuneka ziqwalaselwe ngokupheleleyo kwinkqubo yokwenyani: ukusebenza kakuhle kokunyibilika, izinto zokunyibilikisa, iinxalenye ze-lining corrosion yesithando somlilo esiphakathi, kunye nesigqubuthelo somlilo.

Ngaphantsi kweemeko eziqhelekileyo, i-bottom of the intermediate frequency furnace yokuvelisa i-gray iron okanye i-ductile iron ayinayo i-corrod kakhulu (malunga ne-30-50mm), kwaye umgca ophezulu wokujika kwe-coil induction unokucinezelwa.

Kwangaxeshanye, ukuphakama kwayo yonke isikhunta se-crucible kufuneka kube ngumgama ukusuka kwiplani ephezulu yesithando somlilo esisezantsi ukuya kumphakamo othe nkqo weziko ecaleni kwenqwelomoya kunye nobude obumalunga ne-50mm ngaphezulu kweziko ecaleni kwenqwelomoya. Lo mphakamo ulungele i-furnace iron sintering furnace lining, kwaye ukuphakama okuthe ngqo akuchaphazeli Vala isiciko somlilo.

3. Ubungakanani kunye nokumila kwekona

Oku kulula ukuvelisa; iinyawo zendlovu; iziphene, kwaye iphantsi kwentambo yesithando somlilo ixesha elide ukuba ifakwe kwintsimbi etyhidiweyo kwaye ayinakubonwa, ngoko kufuneka iyilwe ngokufanelekileyo. Xa i-angle ye-inclination inkulu kakhulu, ubukhulu bomgca bunganyuswa, kodwa kulula ukubangela ukuba i-lining ifakwe kwi-knotted, kwaye umonakalo womatshini wokutya nawo unzima; naxa ilandelwa; i-engile encinci ye-bevel inkulu; emva komgaqo, umgca kamva kulula ukuqhina apha. I-compact, kwaye inokwenza ngokwenene impembelelo enamandla yokuchasana nokupompa, ukuxhathisa ukubola kunye nokunyanzeliswa koxinzelelo kwi-slope yesithando somlilo ngexesha lenkqubo yokunyibilika, ngaloo ndlela ugwema iziphene “zendlovu” kunye nokwandisa ubomi benkonzo yomgca wesithando somlilo.

4. Gqoka umngxuma wokukhupha umoya kunye nokumila okusezantsi

4. Gqoka umngxuma wokukhupha umoya kunye nokumila okusezantsi

Imingxunya eyenziwe ngedayimane kufuneka igrunjwe emazantsi, ithambeka kunye neendonga ezisecaleni zesikhunta se-crucible kwithuba le-200 ~ 300mm, elilungele ukukhutshelwa komswakama kwimpahla yombane yomlilo ngexesha lokubhaka kunye nokwandisa ukuchasana, kwaye kuphucula ukufudumeza kunye nefuthe lokubhaka.

Ubukhulu bomngxuma kukhethwa ukuba yi-3mm. Ukuba incinci kakhulu, umphumo wokukhupha uya kuba mbi, kwaye ukuba ukhulu kakhulu, uya kubangela ukuba umthamo omkhulu we-lining powder ukhutshwe emngxunyeni xa isithando somlilo sishukunyiswa.

Iplani esezantsi yokungunda okubethelelweyo ayinakuphinda ibuyele ngaphakathi, ithe tyaba, okanye iphume malunga ne-1mm ukusuka embindini, ukuze uthintele umsantsa womoya kunye noxinzelelo lwesakhiwo emazantsi eziko emva kokwakhiwa komlilo, okunokubangela “ezantsi”. ugqabhuko-dubulo” ngexesha lokubhaka kunye nokuntywila.

5. Abanye

Zonke iiwelds kufuneka zicocwe kakuhle kwaye akukho sinyibilikisi se-welding okanye iikona ezibukhali zivunyelwe; ukunyamezela kunye nokugxilwa kwesangqa sangaphandle se-crucible mold kufuneka ilawulwe ngaphakathi kwe-5mm; i-crucible mold kufuneka idutyulwe iqhunyiswe phambi kokusetyenziswa.