- 23

- May

Ci gaba da simintin tundish narkakkar karfe induction kayan aikin dumama

Ci gaba da simintin tundish narkakkar karfe induction kayan aikin dumama

Labarin 1

Tundish molten steel induction dumama kayan aiki technology is developed with the progress of continuous casting technology, the improvement of steel quality requirements, the need for energy saving and consumption reduction, and the matching of external refining and continuous casting processes. Different steel grades have different requirements on the AT of molten steel superheat. For thick plates, in order to reduce internal cracks and loose center, the AT should be low (5~200T); for cold-rolled thin plates, the surface is required to have good quality. Higher (15~300℃). However, the molten steel superheat must be stabilized within a certain range to minimize fluctuations. This is a necessary condition to ensure the smooth progress of continuous casting production, prevent nozzle blockage or prevent leaking accidents, and ensure the quality of cast slabs. The enhancement of the heating function of the tundish makes it possible to control the superheat of molten steel stably. The temperature of the molten steel of different ladle fluctuates, which has an adverse effect on the continuous casting process, and the heating of the tundish can compensate for it to some extent. However, it must be pointed out that maintaining a stable molten steel superheat mainly depends on the proper tapping temperature and the adjustment structure after tapping, and the tundish heating can only play a supplementary role. Nevertheless, the heating and control of molten steel in the tundish is still receiving attention from the metallurgical community. Some countries represented by Japan, the United States, the United Kingdom, and France have successively carried out research on tundish molten steel heating technology from the 1970s to the 1980s. Japan’s Kawasaki Company first developed and obtained a Japanese patent as early as 1982. At present, the tundish molten steel heating technology successfully developed or under development usually adopts the physical heating method. In the physical heating method, electric energy is used as the heat source and converted according to the electric energy. Different mechanisms can be divided into: electromagnetic induction heating equipment, plasma heating, electroslag heating and DC ceramic heating technology.

Tundish induction kayan aikin dumama yana da halaye masu zuwa:

(1) Gudun dumama da sauri da ingantaccen dumama wutar lantarki;

(2) Wasu nau’ikan kuma suna da wani tasiri na motsa jiki na lantarki, wanda ke taimakawa wajen kawar da abubuwan da aka haɗa;

(3) Tsarin zafin jiki yana da sauƙin sarrafawa, kuma abu mafi mahimmanci shine don sarrafa mafi daidaitaccen zafi na narkakken ƙarfe;

(4) Ƙarfin dumama yana iyakance ta zurfin matakin ruwan tundish. Sai kawai lokacin da narkakken ƙarfe a cikin tundish ya taru zuwa wani zurfin zurfi, dumama na iya ci gaba da sauƙi.

Akwai nau’o’in kayan aikin induction na tundish da yawa:

(1) Dangane da nau’in inductor, ana iya raba shi zuwa kayan aikin dumama induction mara tushe da kayan aikin dumama induction;

(2) Dangane da tsarin inductor, ana iya raba shi zuwa nau’in nau’in kuskure da nau’in rami (tsagi, narkakkar rami) induction dumama kayan aiki;

(3) Dangane da ɓangaren dumama, ana iya raba shi zuwa dumama gida da dumama gabaɗaya.

2 Ci gaba da yin simintin tundish narkakkar karfe electromagnetic induction dumama kayan aikin

2. 1 Tundish electromagnetic induction dumama kayan aikin da ya dace da na’ura mai ci gaba a kwance

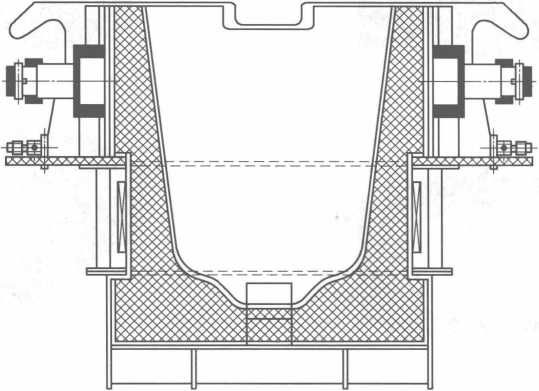

Tundish electromagnetic induction induction kayan dumama wanda yayi daidai da injin ci gaba da simintin kwance ana nuna shi a hoto 10-7.

Yanzu an bayyana tsarin samar da masana’anta na bakin karfe.

Hoto 10-7 Tundish electromagnetic induction dumama kayan aikin da ya dace da injin ci gaba da simintin a kwance

Bayan kowane nau’in bakin karfe an baje, an ɗora su a cikin tanderun induction na 5t guda uku daga tankin ciyarwa tare da cranes. Bayan an narkar da tarkacen karfen zuwa zafin da ake bukata (kimanin 1650°C), za a zuba narkakken karfen da ke cikin tanderun induction a cikin ladle, sannan a yi amfani da shi Motar ta zuba narkakken karfen a cikin tanderun AOD mai lamba 8, inda aka lalata ta. slagging, dephosphorization da sulfur cirewa, da daidaitawa na gami abun da ke ciki (yafi Cr, Ni), sa’an nan narkakkar karfe (na abun da ke ciki da kuma zafin jiki cika da bukatun) Saka narkakkar karfe a cikin ladle da kuma amfani da crane don zuba. narkakkar karfe a cikin ladle cikin ladle na 8t electromagnetic induction dumama kayan aikin. Ruwan bakin karfe mai dumama ta hanyar adana zafi ana zana shi kuma a jefa shi cikin wani shinge mai zagaye ta na’ura mai ci gaba da yin simintin kwance a kwance kuma a karshe an tura shi cikin gadon sanyaya ta hanyar kafawa da yankewa. .

Bayan kowane nau’in bakin karfe an baje, an ɗora su a cikin tanderun induction na 5t guda uku daga tankin ciyarwa tare da cranes. Bayan an narkar da tarkacen karfen zuwa zafin da ake bukata (kimanin 1650°C), za a zuba narkakken karfen da ke cikin tanderun induction a cikin ladle, sannan a yi amfani da shi Motar ta zuba narkakken karfen a cikin tanderun AOD mai lamba 8, inda aka lalata ta. slagging, dephosphorization da sulfur cirewa, da daidaitawa na gami abun da ke ciki (yafi Cr, Ni), sa’an nan narkakkar karfe (na abun da ke ciki da kuma zafin jiki cika da bukatun) Saka narkakkar karfe a cikin ladle da kuma amfani da crane don zuba. narkakkar karfe a cikin ladle cikin ladle na 8t electromagnetic induction dumama kayan aikin. Ruwan bakin karfe mai dumama ta hanyar adana zafi ana zana shi kuma a jefa shi cikin wani shinge mai zagaye ta na’ura mai ci gaba da yin simintin kwance a kwance kuma a karshe an tura shi cikin gadon sanyaya ta hanyar kafawa da yankewa. .

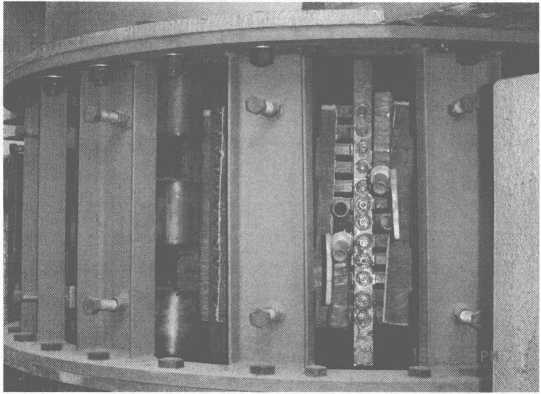

Abu na zahiri na 8t electromagnetic induction dumama kayan ladle yana nunawa a cikin hoto 10-8.

8t da 14t tundish electromagnetic induction dumama kayan aiki, tundish induction dumama kayan aikin na iya sarrafa zafin narkakken ƙarfe daidai da daidai (daidaitaccen kewayon kuskure shine ± 5 ~ 6 ℃), don haka tabbatar da ingancin billet. Bugu da kari, lokacin daidaita yanayin zafi na tundish kuma za’a iya tsawaita shi yadda ya kamata, yana nuna kyakkyawan tasirin shigar da kayan dumama.

2. 2 Tundish na’urar induction dumama na’ura na baka ci gaba da simintin gyaran kafa

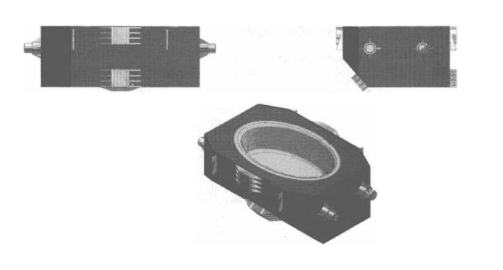

Na’urar tundish na induction dumama na’ura na arc ci gaba da simintin simintin an nuna a cikin Hoto 10-9.

Bayan da arc billet ci gaba da caster ya karɓi na’urar dumama na’urar induction na lantarki tundish, ana iya saukar da zafin bugun bugun (misali, yana iya zama.

Hoto 10-9 Tundish na’urar induction dumama na’ura mai ci gaba da simintin simintin gyare-gyare

Daga 1700 ° C zuwa 1650 ° C), wannan ba kawai yana taimakawa wajen inganta rayuwar rufin ƙarfe na ƙarfe ba (mai canzawa, wutar lantarki ko tanderun shigar da wutar lantarki), amma kuma yana daidaita zafin narkakken ƙarfe a ci gaba da simintin gyare-gyare kuma yana ba da garantin ingancin ci gaba. yin jita-jita.

Dangane da gabatarwar da ke sama, ana iya la’akari da cewa ci gaba da simintin tundish Magnetic induction kayan dumama sabuwar fasaha ce mai ceton kuzari da kuma yanayin muhalli. Ɗaukar wannan na’urar kyakkyawan aiki ne na canza fasaha don masana’antun ƙarfe, kuma ya cancanci haɓakawa da amfani.

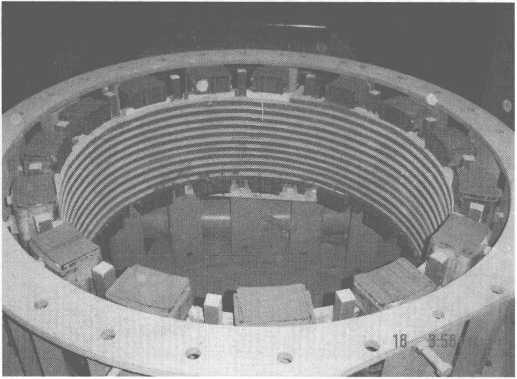

Hoto 10-10 yana nuna 16t tundish electromagnetic induction dumama kayan aikin.

Hoto 10-10 16t tundish electromagnetic induction dumama kayan aikin

Hoto na 10-11 zane ne na tsari na tundish na 14t induction kayan dumama.

Hoto 10-11 Tsarin tsari na tundish na 14t induction kayan dumama