- 23

- May

Tuubitaanka joogtada ah ee tundish birta dhalaalaysa ee qalabka kuleylinta

Tuubitaanka joogtada ah ee tundish birta dhalaalaysa ee qalabka kuleylinta

Guudmarka 1

Tundish molten steel Qalabka kululeynta la-galinta technology is developed with the progress of continuous casting technology, the improvement of steel quality requirements, the need for energy saving and consumption reduction, and the matching of external refining and continuous casting processes. Different steel grades have different requirements on the AT of molten steel superheat. For thick plates, in order to reduce internal cracks and loose center, the AT should be low (5~200T); for cold-rolled thin plates, the surface is required to have good quality. Higher (15~300℃). However, the molten steel superheat must be stabilized within a certain range to minimize fluctuations. This is a necessary condition to ensure the smooth progress of continuous casting production, prevent nozzle blockage or prevent leaking accidents, and ensure the quality of cast slabs. The enhancement of the heating function of the tundish makes it possible to control the superheat of molten steel stably. The temperature of the molten steel of different ladle fluctuates, which has an adverse effect on the continuous casting process, and the heating of the tundish can compensate for it to some extent. However, it must be pointed out that maintaining a stable molten steel superheat mainly depends on the proper tapping temperature and the adjustment structure after tapping, and the tundish heating can only play a supplementary role. Nevertheless, the heating and control of molten steel in the tundish is still receiving attention from the metallurgical community. Some countries represented by Japan, the United States, the United Kingdom, and France have successively carried out research on tundish molten steel heating technology from the 1970s to the 1980s. Japan’s Kawasaki Company first developed and obtained a Japanese patent as early as 1982. At present, the tundish molten steel heating technology successfully developed or under development usually adopts the physical heating method. In the physical heating method, electric energy is used as the heat source and converted according to the electric energy. Different mechanisms can be divided into: electromagnetic induction heating equipment, plasma heating, electroslag heating and DC ceramic heating technology.

Qalabka kuleylinta induction ee Tundish waxay leedahay sifooyinka soo socda:

(1) Xawaaraha kuleyliyaha degdega ah iyo waxtarka kuleylka korantada oo sarreeya;

(2) Noocyada qaarkood waxay sidoo kale leeyihiin saameyn kicinta korantada, taas oo u sahlaysa ka saarista ku darida;

(3) Heerkulka geeddi-socodka waa sahlan tahay in la xakameeyo, iyo waxa ugu muhiimsan waa in si sax ah loo xakameeyo kulaylka sare ee birta dhalaalaysa;

(4) Awoodda kuleyliyaha waxaa xaddiday qoto dheer ee heerka dareeraha tundish. Kaliya marka birta dhalaalaysa ee tundishku ay ku ururto qoto dheer, kuleylku wuxuu u socon karaa si habsami leh.

Waxaa jira dhowr nooc oo ah qalabka kuleylinta induction tundish:

(1) Marka loo eego nooca inductor, waxaa loo qaybin karaa qalab kuleyliyaha induction-ka aan xudunta lahayn iyo qalabka kuleyliyaha induction-ka;

(2) Marka loo eego qaab-dhismeedka inductor-ka, waxa loo qaybin karaa nooca cilladda oo kordhay iyo nooca tunnel-ka (jeexdin, godad dhalaalaysa) qalabka kuleylinta induction;

(3) Marka loo eego qaybta kuleyliyaha, waxaa loo qaybin karaa kuleyliyaha deegaanka iyo kuleylka guud.

2 Tuubista joogtada ah ee tundish birta dhalaalaysa ee qalabka kuleyliyaha induction electromagnetic

2. 1 Qalabka kuleyliyaha induction ee Tundish oo ku habboon mashiinka shubista joogtada ah ee jiifka ah

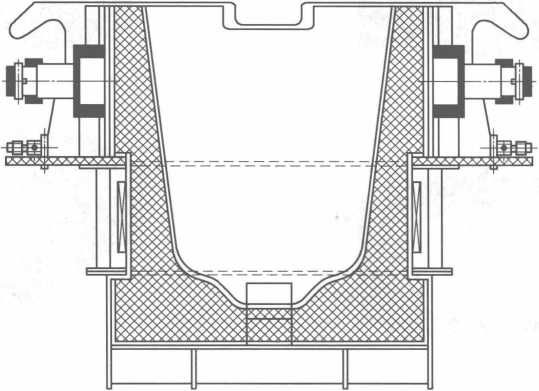

Qalabka kuleylinta soo-saarka korantada ee tundish oo ku habboon mashiinka shubista joogtada ah ee tooska ah ayaa lagu muujiyey Jaantuska 10-7.

Habka wax-soo-saarka ee warshad birta aan lahayn ayaa hadda la sharraxay.

Jaantus 10-7 Qalabka kuleylinta soo-saarka korantada ee Tundish oo ku habboon mashiinka shubista joogtada ah ee jiifka ah

Ka dib marka dhammaan noocyada kala duwan ee birta aan la kala saarin, waxaa lagu shubaa saddex foornooyinka 5t ee foornooyinka quudinta oo leh wiishash. Ka dib markii birta qashinka lagu dhalaaliyo heerkulka loo baahan yahay (qiyaastii 1650 ° C), birta dhalaalaysa ee foornada induction ayaa lagu shubaa godka, ka dibna la isticmaalo Gaarigu wuxuu ku shubaa birta dhalaalaysa foornada 8t AOD, halkaas oo ay marayso decarburization. dharbaaxada, dephosphorization iyo ka saarida baaruud, iyo hagaajinta ka kooban Alloy (inta badan Cr, Ni), ka dibna birta dhalaalaysa (halabuurka iyo heerkulka buuxiyey shuruudaha) Ku rid birta dhalaalaysa ee saqafka dhexda oo isticmaal wiishka si aad ugu shubto. birta dhalaalaysa ee ku dhex jirta suunka dhexda ee 8t qalabka kulaylinta induction electromagnetic. Dareeraha birta ah ee lagu kululeeyo kulaylka ayaa la sawiraa oo lagu tuuray baarka wareegsan mashiinka wax shubida joogtada ah ee joogtada ah oo ugu dambeyntii ku riixay sariirta qaboojinta adoo sameeynaya oo xiiraya. .

Ka dib marka dhammaan noocyada kala duwan ee birta aan la kala saarin, waxaa lagu shubaa saddex foornooyinka 5t ee foornooyinka quudinta oo leh wiishash. Ka dib markii birta qashinka lagu dhalaaliyo heerkulka loo baahan yahay (qiyaastii 1650 ° C), birta dhalaalaysa ee foornada induction ayaa lagu shubaa godka, ka dibna la isticmaalo Gaarigu wuxuu ku shubaa birta dhalaalaysa foornada 8t AOD, halkaas oo ay marayso decarburization. dharbaaxada, dephosphorization iyo ka saarida baaruud, iyo hagaajinta ka kooban Alloy (inta badan Cr, Ni), ka dibna birta dhalaalaysa (halabuurka iyo heerkulka buuxiyey shuruudaha) Ku rid birta dhalaalaysa ee saqafka dhexda oo isticmaal wiishka si aad ugu shubto. birta dhalaalaysa ee ku dhex jirta suunka dhexda ee 8t qalabka kulaylinta induction electromagnetic. Dareeraha birta ah ee lagu kululeeyo kulaylka ayaa la sawiraa oo lagu tuuray baarka wareegsan mashiinka wax shubida joogtada ah ee joogtada ah oo ugu dambeyntii ku riixay sariirta qaboojinta adoo sameeynaya oo xiiraya. .

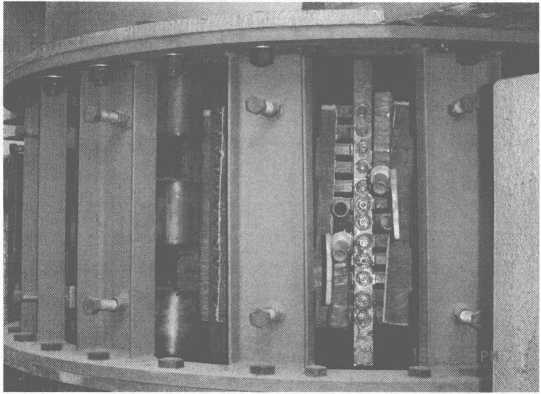

Shayga jireed ee 8t ee qalabka kuleyliyaha induction electromagnetic waxaa lagu muujiyey Jaantuska 10-8.

8t iyo 14t tundish electromagnetic induction qalabka kuleylinta, qalabka kuleylinta induction tundish ayaa si adag oo sax ah u xakameyn kara heerkulka birta dhalaalaysa (kala duwanaanshaha khaladku waa ± 5 ~ 6 ℃), sidaas darteed hubinta tayada billet. Intaa waxaa dheer, wakhtiga hagaajinta heerkulka tundishka ayaa sidoo kale si habboon loo kordhin karaa, taas oo muujinaysa saameynta wanaagsan ee qalabka kuleylinta induction.

2. 2 Qalabka Tundish ee qalabka kuleylka kicinta ee mashiinka tuurista joogtada ah

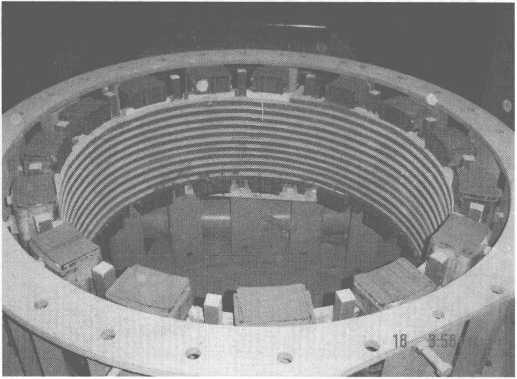

Qalabka tundish ee qalabka kuleyliyaha induction ee mashiinka tuurista joogtada ah ee arc ayaa lagu muujiyay sawirka 10-9.

Ka dib kabka billet-ka joogtada ah uu qaato qalabka kuleyliyaha induction electromagnetic tundish, heerkulka tuubada waa la dhimi karaa (tusaale ahaan, waxay noqon kartaa

Jaantuska 10-9 Qalabka Tundish ee qalabka kuleyliyaha induction ee mashiinka shubka joogtada ah

Laga soo bilaabo 1700 ° C ilaa 1650 ° C), tani kaliya kama caawineyso hagaajinta nolosha dahaarka foornada birta (bedelaha, foornada arc korantada ama foornada induction), laakiin sidoo kale waxay dejisaa heerkulka birta dhalaalaysa ee shubka joogtada ah waxayna dammaanad qaadaysaa tayada joogtada ah tuurista biilasha.

Iyada oo ku saleysan hordhaca sare, waxaa loo qaadan karaa in tuurista joogtada ah ee tundish magnetic induction qalabka kuleylinta ay tahay tignoolajiyad cusub oo tamarta badbaadinaysa iyo deegaanka-saaxiibtinimo. Qaadashada qalabkani waa mashruuc isbeddel teknooloji ah oo ku habboon shirkadaha birta, waana mid mudan in la dhiirrigeliyo lana isticmaalo.

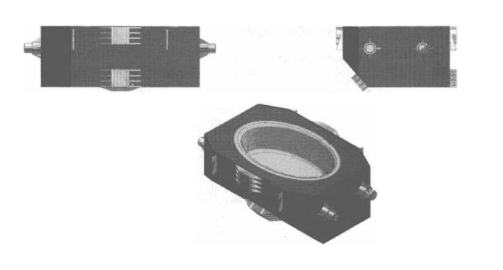

Jaantuska 10-10 wuxuu muujinayaa 16t tundish elektromagnetic induction qalabka kuleylinta.

Jaantus 10-10 16t tundish electromagnetic induction qalab kulaylinta

Jaantuska 10-11 waa jaantus jaantus ah oo ku saabsan tundish ee 14t qalab kulaylinta induction.

Jaantuska 10-11 Jaantuska jaantuska ee tundish ee 14t qalabka kuleylinta induction