- 23

- May

Kuendelea kutupa tundish chuma kuyeyushwa introduktionsutbildning vifaa vya kupokanzwa

Kuendelea kutupa tundish chuma kuyeyushwa introduktionsutbildning vifaa vya kupokanzwa

Muhtasari wa 1

Tundish molten steel vifaa vya kupokanzwa induction technology is developed with the progress of continuous casting technology, the improvement of steel quality requirements, the need for energy saving and consumption reduction, and the matching of external refining and continuous casting processes. Different steel grades have different requirements on the AT of molten steel superheat. For thick plates, in order to reduce internal cracks and loose center, the AT should be low (5~200T); for cold-rolled thin plates, the surface is required to have good quality. Higher (15~300℃). However, the molten steel superheat must be stabilized within a certain range to minimize fluctuations. This is a necessary condition to ensure the smooth progress of continuous casting production, prevent nozzle blockage or prevent leaking accidents, and ensure the quality of cast slabs. The enhancement of the heating function of the tundish makes it possible to control the superheat of molten steel stably. The temperature of the molten steel of different ladle fluctuates, which has an adverse effect on the continuous casting process, and the heating of the tundish can compensate for it to some extent. However, it must be pointed out that maintaining a stable molten steel superheat mainly depends on the proper tapping temperature and the adjustment structure after tapping, and the tundish heating can only play a supplementary role. Nevertheless, the heating and control of molten steel in the tundish is still receiving attention from the metallurgical community. Some countries represented by Japan, the United States, the United Kingdom, and France have successively carried out research on tundish molten steel heating technology from the 1970s to the 1980s. Japan’s Kawasaki Company first developed and obtained a Japanese patent as early as 1982. At present, the tundish molten steel heating technology successfully developed or under development usually adopts the physical heating method. In the physical heating method, electric energy is used as the heat source and converted according to the electric energy. Different mechanisms can be divided into: electromagnetic induction heating equipment, plasma heating, electroslag heating and DC ceramic heating technology.

Vifaa vya kupokanzwa vya induction ya Tundish vina sifa zifuatazo:

(1) Kasi ya kupokanzwa haraka na ufanisi mkubwa wa kupokanzwa kwa umeme;

(2) Aina fulani pia zina athari fulani ya kusisimua ya sumakuumeme, ambayo inafaa kwa kuondolewa kwa inclusions;

(3) Joto la mchakato ni rahisi kudhibiti, na jambo muhimu zaidi ni kudhibiti kwa usahihi zaidi joto la juu la chuma kilichoyeyuka;

(4) Nguvu ya kupokanzwa hupunguzwa na kina cha kiwango cha kioevu cha tundish. Wakati tu chuma kilichoyeyuka kwenye tundish kinajilimbikiza kwa kina fulani, inapokanzwa inaweza kuendelea vizuri.

Kuna aina kadhaa za vifaa vya kupokanzwa vya tundish:

(1) Kulingana na aina ya indukta, inaweza kugawanywa katika vifaa vya kupokanzwa visivyo na msingi na vifaa vya kupokanzwa vya cored;

(2) Kulingana na muundo wa inductor, inaweza kugawanywa katika aina ya kuongezeka kwa kosa na aina ya handaki (Groove, mfereji wa kuyeyuka) vifaa vya kupokanzwa vya induction;

(3) Kulingana na sehemu ya joto, inaweza kugawanywa katika inapokanzwa ndani na inapokanzwa kwa ujumla.

2 Kuendelea akitoa tundish chuma kuyeyuka sumakuumeme introduktionsutbildning vifaa vya kupokanzwa kifaa

2. 1 Tundish vifaa vya kupokanzwa vya sumakuumeme vilivyolingana na mashine ya kutupia inayoendelea ya usawa

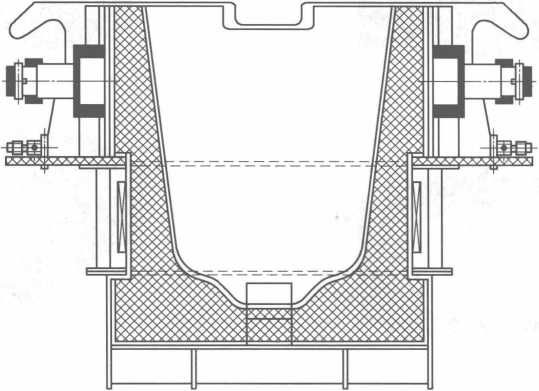

Vifaa vya kupokanzwa vya tundish vya sumakuumeme vinavyowiana na mashine ya utupaji inayoendelea ya mlalo vinaonyeshwa kwenye Mchoro 10-7.

Mchakato wa uzalishaji wa kiwanda cha chuma cha pua sasa umeelezewa.

Mchoro 10-7 Vifaa vya kupokanzwa vya sumakuumeme vya Tundish vilivyolingana na mashine ya kutupia inayoendelea ya mlalo.

Baada ya kila aina ya chuma cha pua kuunganishwa, hupakiwa kwenye tanuu tatu za induction 5t kutoka tank ya kulisha na cranes. Baada ya chuma chakavu kuyeyuka kwa joto linalohitajika (karibu 1650 ° C), chuma kilichoyeyuka kwenye tanuru ya induction hutiwa ndani ya ladle, na kisha kutumika Lori humimina chuma kilichoyeyuka kwenye tanuru ya 8t AOD, ambapo hupitia decarburization; slagging, dephosphorization na kuondolewa kwa salfa, na urekebishaji wa muundo wa aloi (haswa Cr, Ni), na kisha chuma kilichoyeyushwa (muundo na hali ya joto inakidhi mahitaji) Weka chuma kilichoyeyuka kwenye ladi ndani ya ladi na utumie crane kumwaga. chuma kilichoyeyushwa kwenye ladi ndani ya ladi ya vifaa vya kupokanzwa vya 8t vya sumakuumeme. Kioevu cha chuma cha pua kinachopashwa joto kwa kuhifadhi joto huchorwa na kutupwa kwenye upau wa pande zote na mashine ya kutupia inayoendelea mlalo na hatimaye kusukumwa kwenye kitanda cha kupoeza kwa kutengeneza na kukata manyoya. .

Baada ya kila aina ya chuma cha pua kuunganishwa, hupakiwa kwenye tanuu tatu za induction 5t kutoka tank ya kulisha na cranes. Baada ya chuma chakavu kuyeyuka kwa joto linalohitajika (karibu 1650 ° C), chuma kilichoyeyuka kwenye tanuru ya induction hutiwa ndani ya ladle, na kisha kutumika Lori humimina chuma kilichoyeyuka kwenye tanuru ya 8t AOD, ambapo hupitia decarburization; slagging, dephosphorization na kuondolewa kwa salfa, na urekebishaji wa muundo wa aloi (haswa Cr, Ni), na kisha chuma kilichoyeyushwa (muundo na hali ya joto inakidhi mahitaji) Weka chuma kilichoyeyuka kwenye ladi ndani ya ladi na utumie crane kumwaga. chuma kilichoyeyushwa kwenye ladi ndani ya ladi ya vifaa vya kupokanzwa vya 8t vya sumakuumeme. Kioevu cha chuma cha pua kinachopashwa joto kwa kuhifadhi joto huchorwa na kutupwa kwenye upau wa pande zote na mashine ya kutupia inayoendelea mlalo na hatimaye kusukumwa kwenye kitanda cha kupoeza kwa kutengeneza na kukata manyoya. .

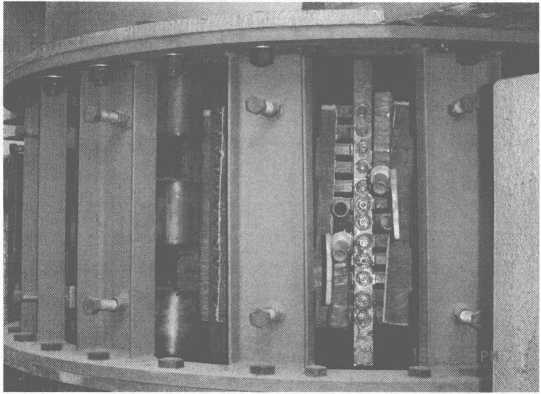

Kitu cha kimwili cha ladi ya vifaa vya kupokanzwa vya 8t vya umeme vya induction inaonyeshwa kwenye Mchoro 10-8.

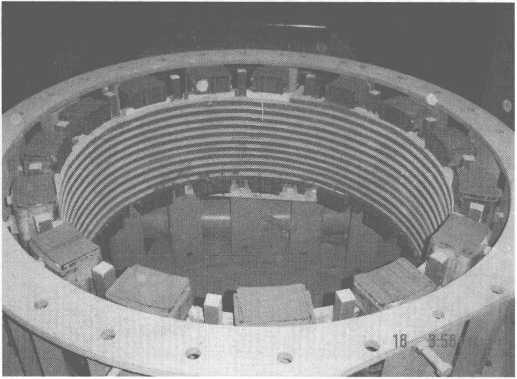

8t na 14t tundish sumakuumeme introduktionsutbildning introduktionsutbildning vifaa vya kupokanzwa, tundish introduktionsutbildning inapokanzwa inaweza madhubuti na usahihi kudhibiti joto ya chuma kuyeyuka (aina ya makosa ni ± 5 ~ 6 ℃ tu), hivyo kuhakikisha ubora wa billet. Kwa kuongeza, wakati wa marekebisho ya joto ya tundish pia inaweza kupanuliwa ipasavyo, kuonyesha athari nzuri ya vifaa vya kupokanzwa induction.

2. 2 Kifaa cha Tundish cha vifaa vya kupokanzwa induction ya arc kuendelea akitoa mashine

Kifaa cha tundish cha vifaa vya kupokanzwa vya induction ya mashine ya arc inayoendelea ya arc inavyoonyeshwa kwenye Mchoro 10-9.

Baada ya caster ya arc billet inayoendelea kupitisha tundish ya vifaa vya kupokanzwa vya induction ya umeme, joto la kugonga linaweza kupunguzwa (kwa mfano, inaweza kuwa

Mchoro 10-9 Kifaa cha Tundish cha vifaa vya kupokanzwa vya induction ya arc kuendelea akitoa mashine

Kuanzia 1700 ° C hadi 1650 ° C), hii sio tu inasaidia kuboresha maisha ya bitana ya tanuru ya kutengeneza chuma (kigeuzi, tanuru ya arc ya umeme au tanuru ya induction), lakini pia huimarisha joto la chuma kilichoyeyushwa katika utupaji unaoendelea na inahakikisha ubora wa kuendelea. akitoa billets.

Kulingana na utangulizi ulio hapo juu, inaweza kuzingatiwa kuwa vifaa vya kupokanzwa vya tundish ya sumaku inayoendelea ni teknolojia mpya ya kuokoa nishati na rafiki wa mazingira. Kupitishwa kwa kifaa hiki ni mradi bora wa mabadiliko ya kiteknolojia kwa makampuni ya metallurgiska, na inastahili kukuza na matumizi.

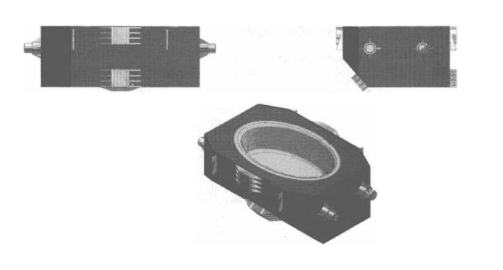

Kielelezo 10-10 kinaonyesha vifaa vya kupokanzwa vya 16t tundish vya umeme vya induction.

Kielelezo 10-10 16t tundish vifaa vya kupokanzwa vya induction ya umeme

Mchoro wa 10-11 ni mchoro wa mchoro wa tundish ya vifaa vya kupokanzwa vya induction 14t.

Mchoro 10-11 mchoro wa mpangilio wa tundish ya vifaa vya kupokanzwa vya 14t