- 23

- May

Kuponyera mosalekeza kwa tundish chitsulo chosungunula chotenthetsera zida zotenthetsera

Kuponyera mosalekeza kwa tundish chitsulo chosungunula chotenthetsera zida zotenthetsera

1 Mwachidule

Tundish molten steel zida zotentha technology is developed with the progress of continuous casting technology, the improvement of steel quality requirements, the need for energy saving and consumption reduction, and the matching of external refining and continuous casting processes. Different steel grades have different requirements on the AT of molten steel superheat. For thick plates, in order to reduce internal cracks and loose center, the AT should be low (5~200T); for cold-rolled thin plates, the surface is required to have good quality. Higher (15~300℃). However, the molten steel superheat must be stabilized within a certain range to minimize fluctuations. This is a necessary condition to ensure the smooth progress of continuous casting production, prevent nozzle blockage or prevent leaking accidents, and ensure the quality of cast slabs. The enhancement of the heating function of the tundish makes it possible to control the superheat of molten steel stably. The temperature of the molten steel of different ladle fluctuates, which has an adverse effect on the continuous casting process, and the heating of the tundish can compensate for it to some extent. However, it must be pointed out that maintaining a stable molten steel superheat mainly depends on the proper tapping temperature and the adjustment structure after tapping, and the tundish heating can only play a supplementary role. Nevertheless, the heating and control of molten steel in the tundish is still receiving attention from the metallurgical community. Some countries represented by Japan, the United States, the United Kingdom, and France have successively carried out research on tundish molten steel heating technology from the 1970s to the 1980s. Japan’s Kawasaki Company first developed and obtained a Japanese patent as early as 1982. At present, the tundish molten steel heating technology successfully developed or under development usually adopts the physical heating method. In the physical heating method, electric energy is used as the heat source and converted according to the electric energy. Different mechanisms can be divided into: electromagnetic induction heating equipment, plasma heating, electroslag heating and DC ceramic heating technology.

Zida zotenthetsera za Tundish zili ndi izi:

(1) Kutentha kwachangu komanso kuthamanga kwamphamvu kwamagetsi;

(2) Mitundu ina imakhalanso ndi mphamvu yamagetsi yamagetsi, yomwe imathandizira kuchotsedwa kwa inclusions;

(3) Kutentha kwa ndondomekoyi n’kosavuta kulamulira, ndipo chofunika kwambiri ndikuwongolera molondola kutentha kwakukulu kwachitsulo chosungunuka;

(4) Kutentha kwamphamvu kumachepetsedwa ndi kuya kwa mulingo wamadzimadzi a tundish. Pokhapokha pamene chitsulo chosungunula mu tundish chiwunjikana mpaka kukuya kwina, kutentha kumatha kuyenda bwino.

Pali mitundu ingapo ya zida zotenthetsera za tundish:

(1) Malinga ndi mtundu wa inductor, imatha kugawidwa m’zida zotenthetsera zopanda coreless ndi zida zotenthetsera za cored;

(2) Malinga ndi kapangidwe ka inductor, imatha kugawidwa m’mitundu yowonjezereka yolakwika ndi mtundu wa ngalande (groove, ngalande yosungunuka) zida zotenthetsera;

(3) Malinga ndi gawo lotenthetsera, limatha kugawidwa m’malo otentha komanso kutentha kwathunthu.

2 Kuponyera mosalekeza tundish chitsulo chosungunula chamagetsi opangira zida zotenthetsera

2. 1 Tundish electromagnetic induction induction zida zofananira ndi yopingasa yopitilira makina oponyera

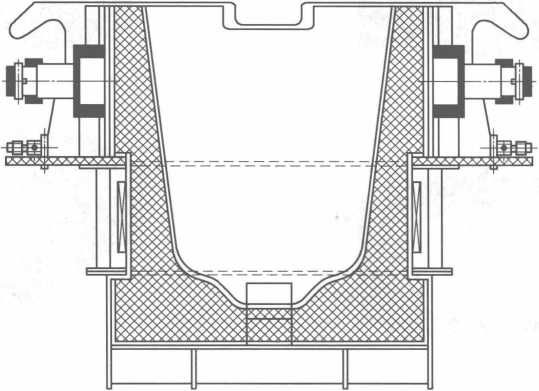

Zida zotenthetsera za tundish electromagnetic induction induction zofananira ndi makina oponyera mosalekeza akuwonetsedwa Chithunzi 10-7.

Njira yopangira zitsulo zosapanga dzimbiri tsopano ikufotokozedwa.

Chithunzi 10-7 Tundish electromagnetic induction induction zida zofananira ndi yopingasa yopitilira makina oponyera

Mitundu yonse ya zitsulo zosapanga dzimbiri ikalumikizidwa, imakwezedwa m’ng’anjo zitatu za 5t kuchokera mu tanki yodyetsera yokhala ndi ma cranes. Chitsulo chachitsulo chikasungunuka mpaka kutentha kofunikira (pafupifupi 1650 ° C), chitsulo chosungunula mu ng’anjo yolowetsamo chimatsanuliridwa mu ladle, ndiyeno chimagwiritsidwa ntchito Galimotoyo imatsanulira chitsulo chosungunuka mu ng’anjo ya 8t AOD, kumene imadutsa decarburization, slagging, dephosphorization ndi kuchotsa sulfure, ndi kusintha kwa aloyi zikuchokera (makamaka Cr, Ni), ndiyeno chitsulo chosungunuka (kupangidwa ndi kutentha kumakwaniritsa zofunikira) Ikani chitsulo chosungunuka mu ladle mu ladle ndikugwiritsa ntchito crane kutsanulira. chitsulo chosungunula mu ladle mu ladle ya 8t electromagnetic induction zida zotenthetsera. Madzi achitsulo chosapanga dzimbiri omwe amatenthedwa ndi kusungidwa kwa kutentha amakokedwa ndikuponyedwa mu bar yozungulira ndi makina opingasa mosalekeza ndipo pamapeto pake amakankhira pabedi lozizirira popanga ndi kumeta ubweya. .

Mitundu yonse ya zitsulo zosapanga dzimbiri ikalumikizidwa, imakwezedwa m’ng’anjo zitatu za 5t kuchokera mu tanki yodyetsera yokhala ndi ma cranes. Chitsulo chachitsulo chikasungunuka mpaka kutentha kofunikira (pafupifupi 1650 ° C), chitsulo chosungunula mu ng’anjo yolowetsamo chimatsanuliridwa mu ladle, ndiyeno chimagwiritsidwa ntchito Galimotoyo imatsanulira chitsulo chosungunuka mu ng’anjo ya 8t AOD, kumene imadutsa decarburization, slagging, dephosphorization ndi kuchotsa sulfure, ndi kusintha kwa aloyi zikuchokera (makamaka Cr, Ni), ndiyeno chitsulo chosungunuka (kupangidwa ndi kutentha kumakwaniritsa zofunikira) Ikani chitsulo chosungunuka mu ladle mu ladle ndikugwiritsa ntchito crane kutsanulira. chitsulo chosungunula mu ladle mu ladle ya 8t electromagnetic induction zida zotenthetsera. Madzi achitsulo chosapanga dzimbiri omwe amatenthedwa ndi kusungidwa kwa kutentha amakokedwa ndikuponyedwa mu bar yozungulira ndi makina opingasa mosalekeza ndipo pamapeto pake amakankhira pabedi lozizirira popanga ndi kumeta ubweya. .

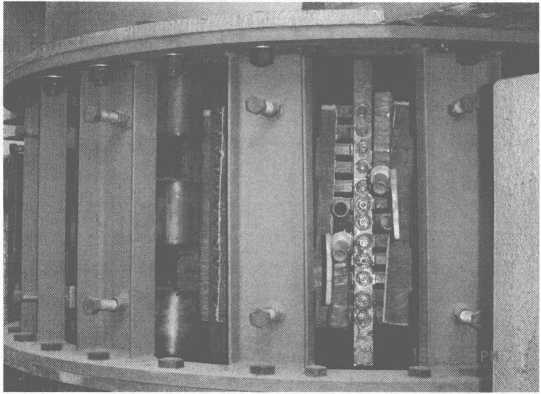

Chinthu chakuthupi cha 8t electromagnetic induction heat equipment ladle chikuwonetsedwa Chithunzi 10-8.

8t ndi 14t tundish electromagnetic induction induction zida zotenthetsera, zida zotenthetsera za tundish zimatha kuwongolera kutentha kwachitsulo chosungunula (zolakwika ndi ± 5 ~ 6 ℃), motero zimatsimikizira mtundu wa billet. Kuphatikiza apo, nthawi yosinthira kutentha kwa tundish imathanso kukulitsidwa moyenera, kuwonetsa zotsatira zabwino za zida zotenthetsera zotenthetsera.

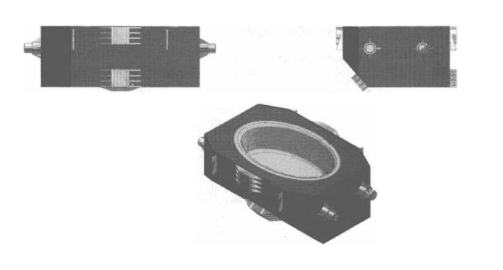

2. 2 Tundish chipangizo cha induction Kutenthetsa zida arc mosalekeza kuponyera makina

Chida cha tundish cha zida zotenthetsera zotenthetsera zamakina opitilira arc zikuwonetsedwa mu Chithunzi 10-9.

Pambuyo pa arc billet continuous caster itengera tundish yamagetsi yotenthetsera magetsi, kutentha kwapampopi kumatha kutsitsidwa (mwachitsanzo, kumatha

Chithunzi 10-9 Tundish chipangizo cha zida zotenthetsera zotenthetsera zamakina opitilira arc

Kuchokera ku 1700 ° C mpaka 1650 ° C), izi sizimangothandiza kukonza moyo wazitsulo zopangira ng’anjo (chotembenuza, ng’anjo yamagetsi yamagetsi kapena ng’anjo yolowera), komanso zimakhazikika kutentha kwachitsulo chosungunula pakuponyedwa kosalekeza ndikutsimikizira ubwino wopitilira. kuponya billets.

Kutengera zomwe tafotokozazi, zitha kuganiziridwa kuti zida zotenthetsera zopitilira tundish maginito ndi njira yatsopano yopulumutsira mphamvu komanso yosunga chilengedwe. Kukhazikitsidwa kwa chipangizochi ndi ntchito yabwino yosinthira ukadaulo wamabizinesi azitsulo, ndipo ndiyoyenera kukwezedwa ndikugwiritsa ntchito.

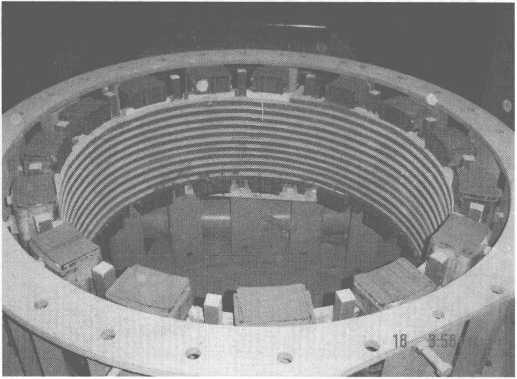

Chithunzi 10-10 chikuwonetsa zida zotenthetsera za 16t tundish electromagnetic induction.

Chithunzi 10-10 16t tundish electromagnetic induction zida zotenthetsera

Chithunzi 10-11 ndi chithunzi chojambula cha tundish ya 14t induction zida zotenthetsera.

Chithunzi 10-11 Schematic chithunzi cha tundish ya 14t induction zida zotenthetsera