- 23

- May

Ukusakaza okuqhubekayo kwe-tundish encibilikisiwe imishini yokushisa yokungeniswa kwensimbi

Ukusakaza okuqhubekayo kwe-tundish encibilikisiwe imishini yokushisa yokungeniswa kwensimbi

Ukubuka konke kwe-1

Tundish molten steel imishini yokushisa yokufakelwa technology is developed with the progress of continuous casting technology, the improvement of steel quality requirements, the need for energy saving and consumption reduction, and the matching of external refining and continuous casting processes. Different steel grades have different requirements on the AT of molten steel superheat. For thick plates, in order to reduce internal cracks and loose center, the AT should be low (5~200T); for cold-rolled thin plates, the surface is required to have good quality. Higher (15~300℃). However, the molten steel superheat must be stabilized within a certain range to minimize fluctuations. This is a necessary condition to ensure the smooth progress of continuous casting production, prevent nozzle blockage or prevent leaking accidents, and ensure the quality of cast slabs. The enhancement of the heating function of the tundish makes it possible to control the superheat of molten steel stably. The temperature of the molten steel of different ladle fluctuates, which has an adverse effect on the continuous casting process, and the heating of the tundish can compensate for it to some extent. However, it must be pointed out that maintaining a stable molten steel superheat mainly depends on the proper tapping temperature and the adjustment structure after tapping, and the tundish heating can only play a supplementary role. Nevertheless, the heating and control of molten steel in the tundish is still receiving attention from the metallurgical community. Some countries represented by Japan, the United States, the United Kingdom, and France have successively carried out research on tundish molten steel heating technology from the 1970s to the 1980s. Japan’s Kawasaki Company first developed and obtained a Japanese patent as early as 1982. At present, the tundish molten steel heating technology successfully developed or under development usually adopts the physical heating method. In the physical heating method, electric energy is used as the heat source and converted according to the electric energy. Different mechanisms can be divided into: electromagnetic induction heating equipment, plasma heating, electroslag heating and DC ceramic heating technology.

Imishini yokushisisa ye-Tundish induction inalezi zimpawu ezilandelayo:

(1) Isivinini sokushisa esisheshayo kanye nokusebenza kahle kokushisa kukagesi;

(2) Ezinye izinhlobo ziphinde zibe nomthelela othile wokunyakazisa kazibuthe, ovumela ukususwa kwezinto ezifakiwe;

(3) Izinga lokushisa lenqubo kulula ukulilawula, futhi into ebaluleke kakhulu ukulawula ngokunembe kakhudlwana ukushisa okukhulu kwensimbi encibilikisiwe;

(4) Amandla okushisa anqunyelwe ukujula kwezinga le-tundish liquid. Kuphela lapho insimbi encibilikisiwe ku-tundish iqoqana ekujuleni okuthile, ukushisa kungaqhubeka kahle.

Kunezinhlobo ezimbalwa zemishini yokushisa ye-tundish induction:

(1) Ngokohlobo lwe-inductor, ingahlukaniswa ibe imishini yokushisa yokungeniswa kwe-coreless kanye nemishini yokushisa yokungeniswa kwe-cored;

(2) Ngokuya ngesakhiwo se-inductor, ingahlukaniswa ngohlobo lwephutha olwandisiwe kanye nohlobo lomhubhe (i-groove, umsele oncibilikisiwe) imishini yokushisa yokungeniswa;

(3) Ngokwengxenye yokushisa, ingahlukaniswa ngokufudumeza kwendawo kanye nokushisa okuphelele.

2 Ukusakaza okuqhubekayo kwe-tundish yensimbi encibilikisiwe ye-electromagnetic induction heat device

2. 1 Imishini yokushisisa ye-electromagnetic induction ye-Tundish ehambisana nomshini wokuphonsa ovundlile oqhubekayo

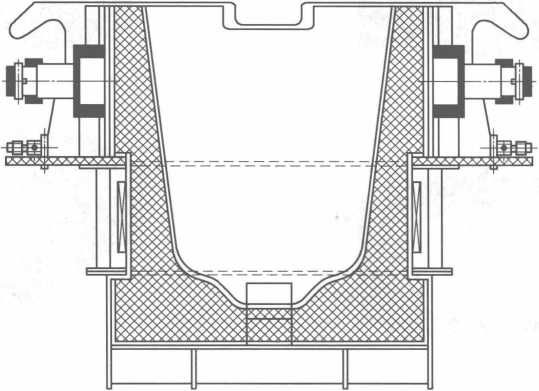

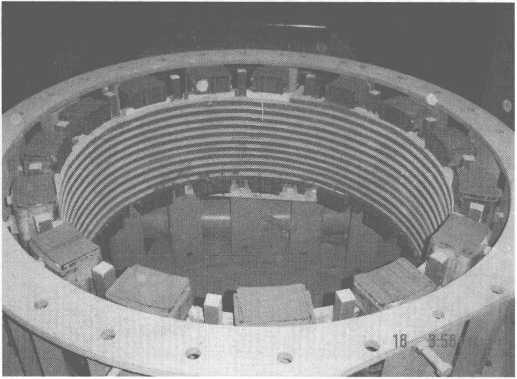

Imishini yokushisa ye-tundish ye-electromagnetic induction ehambisana nomshini wokusakaza ovundlile oqhubekayo uboniswa kuMfanekiso 10-7.

Inqubo yokukhiqiza yesitshalo sensimbi engagqwali isichazwe manje.

Umfanekiso 10-7 Imishini yokushisisa ye-Tundish electromagnetic induction ehambisana nomshini wokuphonsa ovundlile oqhubekayo

Ngemuva kokuthi zonke izinhlobo zensimbi engagqwali zihlanganisiwe, zilayishwa ezithandweni zokungeniswa ze-5t ezintathu ezivela ethangini lokuphakela elinama-cranes. Ngemuva kokuthi insimbi ye-scrap incibilikiswa ekushiseni okudingekayo (cishe i-1650 ° C), insimbi encibilikisiwe esithandweni sokungeniswa ithululelwa ku-ladle, bese isetshenziswa Iloli lithela insimbi encibilikisiwe esithandweni somlilo se-8t AOD, lapho idlula khona i-decarburization, i-slagging, i-dephosphorization kanye nokususwa kwesibabule, nokulungiswa kokwakheka kwe-alloy (ikakhulukazi i-Cr, i-Ni), bese kuba insimbi encibilikisiwe (ukwakheka kanye nezinga lokushisa kuhlangabezana nezidingo) Faka insimbi encibilikisiwe ku-ladle ku-ladle bese usebenzisa i-crane ukuthulula. insimbi encibilikisiwe ku-ladle ku-ladle ye-8t electromagnetic induction heat heat. Uketshezi lwensimbi engagqwali olushisiswe ukugcinwa kokushisa luyadonswa bese luphonswa kubha eyindilinga ngomshini wokuphonsa oqhubekayo ovundlile futhi ekugcineni luphushelwe embhedeni wokupholisa ngokwakha nokugunda. .

Ngemuva kokuthi zonke izinhlobo zensimbi engagqwali zihlanganisiwe, zilayishwa ezithandweni zokungeniswa ze-5t ezintathu ezivela ethangini lokuphakela elinama-cranes. Ngemuva kokuthi insimbi ye-scrap incibilikiswa ekushiseni okudingekayo (cishe i-1650 ° C), insimbi encibilikisiwe esithandweni sokungeniswa ithululelwa ku-ladle, bese isetshenziswa Iloli lithela insimbi encibilikisiwe esithandweni somlilo se-8t AOD, lapho idlula khona i-decarburization, i-slagging, i-dephosphorization kanye nokususwa kwesibabule, nokulungiswa kokwakheka kwe-alloy (ikakhulukazi i-Cr, i-Ni), bese kuba insimbi encibilikisiwe (ukwakheka kanye nezinga lokushisa kuhlangabezana nezidingo) Faka insimbi encibilikisiwe ku-ladle ku-ladle bese usebenzisa i-crane ukuthulula. insimbi encibilikisiwe ku-ladle ku-ladle ye-8t electromagnetic induction heat heat. Uketshezi lwensimbi engagqwali olushisiswe ukugcinwa kokushisa luyadonswa bese luphonswa kubha eyindilinga ngomshini wokuphonsa oqhubekayo ovundlile futhi ekugcineni luphushelwe embhedeni wokupholisa ngokwakha nokugunda. .

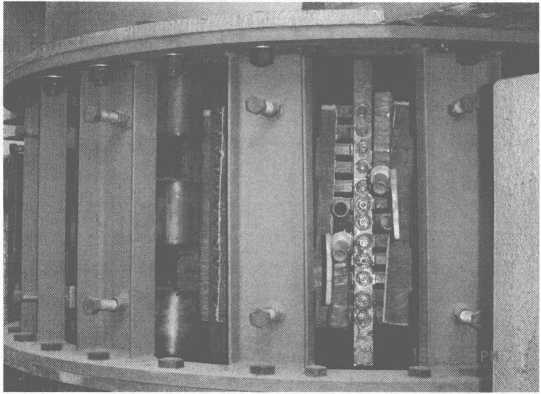

Into ebonakalayo ye-ladle ye-8t ye-electromagnetic induction heat ladle iboniswa kuMfanekiso 10-8.

I-8t kanye ne-14t tundish i-electromagnetic induction heat equipment, imishini yokushisa yokungeniswa kwe-tundish ingalawula ngokuqinile nangokunembile izinga lokushisa lensimbi encibilikisiwe (uhlu lwamaphutha luyi-± 5 ~ 6 ℃ kuphela), ngaleyo ndlela iqinisekise ikhwalithi ye-billet. Ngaphezu kwalokho, isikhathi sokulungiswa kwezinga lokushisa kwe-tundish singanwetshwa ngokufanelekile, sibonise umphumela omuhle wemishini yokushisa yokungeniswa.

2. 2 Idivayisi ye-Tundish yemishini yokushisa yokungeniswa yomshini wokuphonsa we-arc oqhubekayo

Idivayisi ye-tundish yemishini yokushisa yokungeniswa yomshini wokukhipha i-arc oqhubekayo uboniswa kuMfanekiso 10-9.

Ngemuva kokuthi i-arc billet eqhubekayo i-caster ithatha i-tundish yemishini yokushisa yokungeniswa kwe-electromagnetic, izinga lokushisa lokuthinta lingehliswa (isibonelo, lingaba

Umfanekiso 10-9 Idivayisi ye-Tundish yemishini yokushisa yokungeniswa yomshini wokukhipha i-arc oqhubekayo

Ukusuka ku-1700°C kuya ku-1650°C), lokhu akusizi nje kuphela ukuthuthukisa impilo yolayini lwesithando sokwenza insimbi (i-converter, isithando somlilo se-arc kagesi noma isithando somlilo sokungeniswa), kodwa futhi kumisa izinga lokushisa lensimbi encibilikisiwe ekubunjweni okuqhubekayo futhi kuqinisekisa ikhwalithi eqhubekayo. ukuphonsa billets.

Ngokusekelwe esingenisweni esingenhla, kungacatshangwa ukuthi umshini wokushisa oqhubekayo we-tundish magnetic induction ubuchwepheshe obusha bokulondoloza amandla kanye nobungane bemvelo. Ukwamukelwa kwalolu cingo kuwumsebenzi ofanelekile wokuguqulwa kwezobuchwepheshe kumabhizinisi ensimbi, futhi kufanelekile ukukhuthazwa nokusetshenziswa.

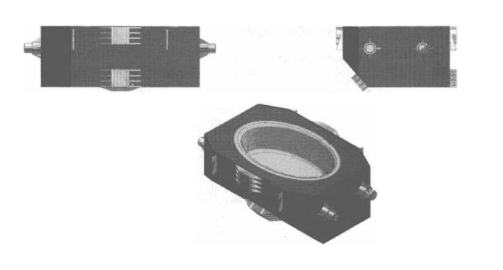

Umfanekiso 10-10 ukhombisa imishini yokushisisa ye-16t tundish electromagnetic induction.

Umfanekiso 10-10 16t tundish i-electromagnetic induction imishini yokushisa

Umfanekiso 10-11 uwumdwebo wohlelo lwe-tundish yemishini yokushisa yokungeniswa kwe-14t.

Umfanekiso 10-11 Umdwebo weSchematic we-tundish ye-14t induction imishini yokushisa