- 23

- May

Ngokuqhubekayo ukugalela tundish otyhidiweyo izixhobo zokufudumeza induction

Ngokuqhubekayo ukugalela tundish otyhidiweyo izixhobo zokufudumeza induction

1 Amagqabantshintshi

Tundish intsimbi etyhidiweyo izixhobo zokufudumeza itekhnoloji iphuhliswa ngenkqubela phambili yetekhnoloji yokuphosa eqhubekayo, ukuphuculwa kweemfuno zomgangatho wentsimbi, imfuno yokonga amandla kunye nokunciphisa ukusetyenziswa, kunye nokuhambelana nokucocwa kwangaphandle kunye neenkqubo eziqhubekayo zokuphosa. Amabakala ensimbi ahlukeneyo aneemfuno ezahlukeneyo kwi-AT ye-superheat yensimbi etyhidiweyo. Kwiipleyiti ezityebileyo, ukwenzela ukunciphisa ukuqhekeka kwangaphakathi kunye neziko elikhululekile, i-AT kufuneka ibe phantsi (5 ~ 200T); kwiipleyiti ezinqabileyo ezibandayo, umphezulu uyafuneka ukuba ube nomgangatho omhle. Phezulu (15~300℃). Nangona kunjalo, i-superheat yensimbi etyhidiweyo kufuneka izinze phakathi koluhlu oluthile ukunciphisa ukuguquguquka. Le yimeko efunekayo yokuqinisekisa inkqubela phambili egudileyo yokuveliswa kwemveliso eqhubekayo, ukuthintela ukuvaleka kwemibhobho okanye ukuthintela iingozi ezivuzayo, kunye nokuqinisekisa umgangatho we-cast slabs. Ukuphuculwa komsebenzi wokufudumeza kwe-tundish kwenza kube lula ukulawula ukushisa okuphezulu kwensimbi etyhidiweyo ngokuzinzileyo. Ubushushu bentsimbi etyhidiweyo ye-ladle ehlukeneyo iyaguquguquka, enefuthe elibi kwinkqubo yokuphosa eqhubekayo, kunye nokufudumeza kwe-tundish kunokubuyisela kwinqanaba elithile. Nangona kunjalo, kufuneka kucaciswe ukuba ukugcina i-superheat yensimbi etyhidiweyo ezinzileyo ngokuyinhloko kuxhomekeke kwiqondo lokushisa elifanelekileyo lokucofa kunye nesakhiwo sohlengahlengiso emva kokucofa, kwaye ukufudumeza kwe-tundish kunokudlala indima eyongezelelweyo kuphela. Nangona kunjalo, ukufudumeza kunye nolawulo lwentsimbi etyhidiweyo kwi-tundish isafumana ingqalelo kuluntu lwe-metallurgical. Amanye amazwe amelwe yi-Japan, i-United States, i-United Kingdom, ne-France aye aqhuba uphando ngokulandelelanayo kwi-tundish etyhidiweyo yetekhnoloji yokufudumeza intsimbi ukusuka koo-1970 ukuya koo-1980. Inkampani yaseJapan yeKawasaki yaqala yaphuhlisa kwaye yafumana ilungelo elilodwa lomenzi wechiza kwaseJapan kwangoko ngo 1982. Okwangoku, iteknoloji yokufudumeza yentsimbi enyibilikisiweyo iphuhliswe ngempumelelo okanye phantsi kophuhliso ihlala ithatha indlela yokufudumeza ngokwasemzimbeni. Kwindlela yokufudumeza ngokwasemzimbeni, amandla ombane asetyenziswa njengomthombo wobushushu kwaye aguqulwa ngokwamandla ombane. Iindlela ezahlukeneyo zinokwahlulwa zibe: izixhobo zokufudumeza nge-electromagnetic induction, ukufudumeza kweplasma, ukufudumeza kwe-electroslag kunye nethekhnoloji yokufudumeza kwe-DC ceramic.

Isixhobo sokufudumeza iTundish sinezi mpawu zilandelayo:

(1) Isantya sokufudumeza ngokukhawuleza kunye nokusebenza kakuhle kokufudumeza kombane;

(2) Ezinye iintlobo zikwanazo nefuthe elithile lombane elishukumisayo, elinceda ukususwa kwezinto ezibandakanyiweyo;

(3) Ubushushu benkqubo bulula ukulawula, kwaye eyona nto ibalulekileyo kukulawula ngokuchanekileyo ngakumbi ukushisa okukhulu kwentsimbi etyhidiweyo;

(4) Amandla okufudumeza anqunyelwe ngobunzulu bomgangatho wolwelo we-tundish. Kuphela xa intsimbi etyhidiweyo kwi-tundish iqokelela kubunzulu obuthile, ukufudumeza kunokuhamba kakuhle.

Kukho iintlobo ezininzi zezixhobo zokufudumeza ze-tundish:

(1) Ngokohlobo lwe-inductor, lunokwahlulwa lube yi-coreless induction heat equipment kunye ne-cored induction heat equipment;

(2) Ngokwesakhiwo se-inductor, inokwahlulwa ibe luhlobo olwandisiweyo lwempazamo kunye nohlobo lwetonela (i-groove, umsele otyhidiweyo) izixhobo zokufudumeza;

(3) Ngokwenxalenye yokufudumeza, inokwahlulwa ibe yindawo yokufudumala yendawo kunye nokufudumeza ngokubanzi.

2 Ngokuqhubekayo ukuphosa i-tundish yensimbi etyhidiweyo ye-electromagnetic induction isixhobo sokufudumeza isixhobo

2. 1 Isixhobo sokufudumeza se-electromagnetic induction ye-Tundish ehambelana nomatshini wokuphosa othe tye oqhubekayo

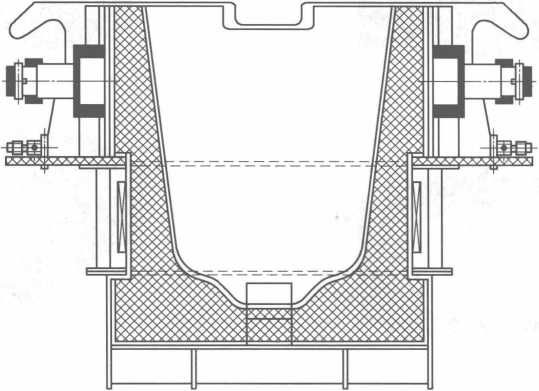

Isixhobo sokufudumala se-electromagnetic induction ye-tundish ehambelana nomatshini wokuphosa othe tye oqhubekayo uboniswe kuMfanekiso 10-7.

Inkqubo yokuvelisa isityalo sensimbi engenasici ichazwa ngoku.

Umzobo 10-7 I-Tundish yezixhobo zokufudumeza ze-electromagnetic ezihambelana nomatshini wokuphosa othe tye oqhubekayo.

Emva kokuba zonke iintlobo zensimbi engenasici zidibene, zilayishwa kwii-furnaces ezintathu ze-5t zokungeniswa kwi-tank yokutya kunye neekrane. Emva kokuba insimbi ye-scrap inyibilika kwiqondo lokushisa elifunekayo (malunga ne-1650 ° C), insimbi etyhidiweyo kwisithando somlilo sokungeniswa igalelwe kwi-ladle, ize isetyenziswe Iloli ithululela insimbi etyhidiweyo kwisithando somlilo se-8t AOD, apho idlula khona i-decarburization, i-slagging, i-dephosphorization kunye nokususwa kwesulfure, kunye nokulungiswa kokwakheka kwe-alloy (ikakhulukazi i-Cr, i-Ni), kunye nentsimbi etyhidiweyo (ukubunjwa kunye nobushushu buhlangabezana neemfuno) Faka intsimbi etyhidiweyo kwi-ladle kwi-ladle kwaye usebenzise i-crane ukugalela. intsimbi etyhidiweyo kwileyidi kwileyidi ye-8t yesixhobo sokufudumeza sombane sombane. Ulwelo lwensimbi engenasici lufudunyezwa kukugcinwa kobushushu lutsalwa kwaye luphoswe kwibha engqukuva ngomatshini wokuphosa othe tye oqhubekayo kwaye ekugqibeleni utyhalelwe kumandlalo wokupholisa ngokwenza kunye nokucheba. .

Emva kokuba zonke iintlobo zensimbi engenasici zidibene, zilayishwa kwii-furnaces ezintathu ze-5t zokungeniswa kwi-tank yokutya kunye neekrane. Emva kokuba insimbi ye-scrap inyibilika kwiqondo lokushisa elifunekayo (malunga ne-1650 ° C), insimbi etyhidiweyo kwisithando somlilo sokungeniswa igalelwe kwi-ladle, ize isetyenziswe Iloli ithululela insimbi etyhidiweyo kwisithando somlilo se-8t AOD, apho idlula khona i-decarburization, i-slagging, i-dephosphorization kunye nokususwa kwesulfure, kunye nokulungiswa kokwakheka kwe-alloy (ikakhulukazi i-Cr, i-Ni), kunye nentsimbi etyhidiweyo (ukubunjwa kunye nobushushu buhlangabezana neemfuno) Faka intsimbi etyhidiweyo kwi-ladle kwi-ladle kwaye usebenzise i-crane ukugalela. intsimbi etyhidiweyo kwileyidi kwileyidi ye-8t yesixhobo sokufudumeza sombane sombane. Ulwelo lwensimbi engenasici lufudunyezwa kukugcinwa kobushushu lutsalwa kwaye luphoswe kwibha engqukuva ngomatshini wokuphosa othe tye oqhubekayo kwaye ekugqibeleni utyhalelwe kumandlalo wokupholisa ngokwenza kunye nokucheba. .

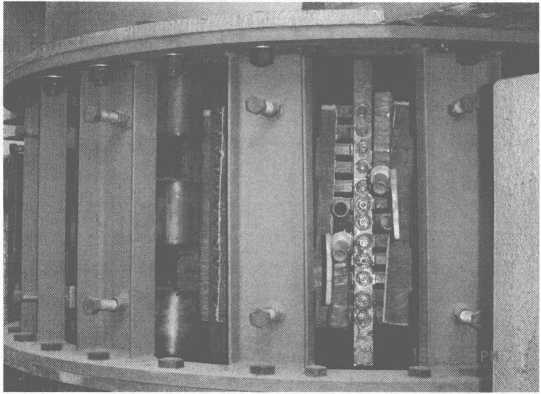

Into ebonakalayo ye-8t ye-electromagnetic induction yesixhobo sokufudumeza iboniswe kuMfanekiso 10-8.

I-8t kunye ne-14t tundish izixhobo zokufudumeza i-electromagnetic induction, izixhobo zokufudumeza ze-tundish zingakwazi ukulawula ngokungqongqo kunye ngokuchanekileyo ubushushu bentsimbi etyhidiweyo (uluhlu lwephutha luyi-± 5 ~ 6 ℃ kuphela), ngaloo ndlela luqinisekisa umgangatho we-billet. Ukongezelela, ixesha lokulungiswa kweqondo lokushisa le-tundish lingakwandiswa ngokufanelekileyo, libonisa umphumo omhle wezixhobo zokufudumeza induction.

2. 2 Isixhobo se-Tundish sezixhobo zokufudumeza zokungeniswa kwe-arc umatshini oqhubekayo wokuphosa

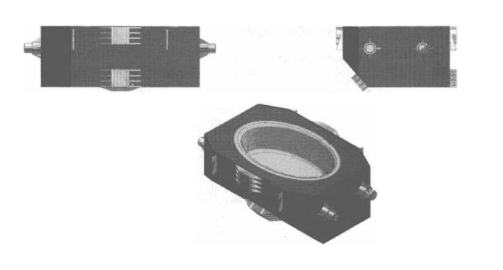

Isixhobo se-tundish sesixhobo sokufudumeza i-induction ye-arc umatshini oqhubekayo wokuphosa uboniswe kuMfanekiso 10-9.

Emva kokuba i-arc billet eqhubekayo i-caster ithatha isixhobo sokufudumeza sokufakelwa kwe-electromagnetic, iqondo lobushushu lokucofa linokwehliswa (umzekelo, linokuba

Umzobo 10-9 Isixhobo se-Tundish sezixhobo zokufudumeza zokungeniswa kwe-arc umatshini oqhubekayo wokuphosa

Ukususela kwi-1700 ° C ukuya kwi-1650 ° C), oku akuncedi nje ukuphucula ubomi bentsimbi yokwenza isithando somlilo (isiguquli, isithando sombane se-arc okanye isithando somlilo), kodwa kwakhona kuzinzisa ubushushu bentsimbi etyhidiweyo ekubunjweni okuqhubekayo kwaye iqinisekisa umgangatho oqhubekayo. ukuphosa iibhilidi.

Ngokusekelwe kwintshayelelo engentla, kunokuqwalaselwa ukuba i-tundish eqhubekayo yokufaka izixhobo zokufudumeza i-magnetic induction iteknoloji entsha yokugcina amandla kunye ne-teknoloji ehambelana nokusingqongileyo. Ukwamkelwa kwesi sixhobo yiprojekthi yenguqu yetekhnoloji efanelekileyo kumashishini esinyithi, kwaye kufanelekile ukukhuthazwa kunye nokusetyenziswa.

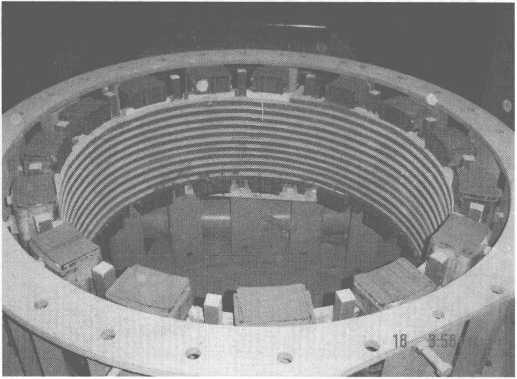

Umzobo we-10-10 ubonisa izixhobo zokufudumeza ze-electromagnetic induction ze-16t.

Umzobo 10-10 16t tundish i-electromagnetic induction zokufudumeza izixhobo

Umzobo we-10-11 ngumzobo oqingqiweyo we-tundish ye-14t izixhobo zokufudumeza induction.

Umzobo we-10-11 umzobo weSchematic we-tundish ye-14t izixhobo zokufudumeza