- 27

- Sep

What is the quenching structure of the large slewing bearing raceway induction heating furnace?

What is the quenching structure of the large slewing bearing raceway induction heating furnace?

Due to the large diameter of the raceway of the traditional bearing inner and outer raceways, 4 ~ 30kHz frequency converter scanning quenching is commonly used for Induktionshärten, and a transition zone (soft zone) of about 30mm is generally left between the quenching start and end points.

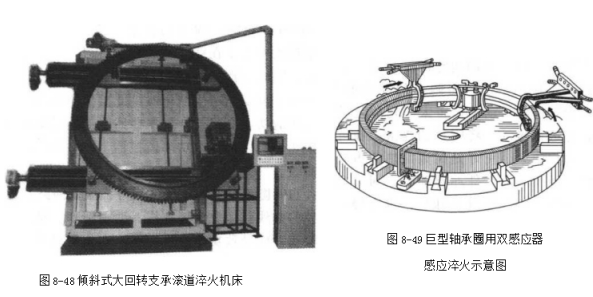

Early slewing bearing raceway quenching machine beds are often used for quenching in large gear induction heating furnaces, which can quench single teeth and scan and quench raceways. Generally, similar to vertical lathes, the gears are placed horizontally. It was later improved to a slope of 75. It is easy to operate and the quenching liquid flows away, as shown in Figure 8-48.

In order to facilitate the hardening of single teeth of gears and the quenching of raceways, a German induction heating company has developed RHM-5 type induction heating furnace quenching which can harden raceways with oblique and horizontal gears. The diameter of the workpiece can reach 6m, the weight can reach 20t.

In recent years, with the development of the wind power industry, slewing bearing raceway scanning hardening without soft belt has once again become a key R&D project of induction heating companies. As early as the 1950s, the former Soviet Union proposed to use two sensors to scan in opposite directions from the starting point for giant bearing rings. Finally, the two sensors merged, and the solution was solved by spraying liquid quenching at the meeting point. The soft belt problem is shown in Figure 8-49.

At present, a new type of induction heating furnace for revolving bearing raceway quenching has been developed at home and abroad. It can connect the hardened layer end to end without soft bands. The mechanism is similar to Figure 849. The two sensors scan in opposite directions from the starting point, and the last two sensors merge. At the point of convergence, the liquid sprayer performs liquid spray quenching. However, the design of the machine tool is very clever, as shown in Figure 8-50. It is like a beam crane with two load systems. The sensors can move up and down, left and right, and the crane can move back and forth, forming a three-dimensional movement space. Therefore, it can handle raceways of different diameters and heights.

For the quenching of smaller diameter raceways, there is also a quenching machine that rotates the workpiece at high speed and heats it with more than one inductor. When all the raceway surfaces reach the quenching temperature, they are sprayed at the same time, so that no softness can be obtained. Hardened layer of belt.