- 12

- Aug

Mene ne hanyoyin da za a iya yin zafi a sassa na induction dumama tanderun?

Menene hanyoyin don tempering quenched sassa na shigowa dumama tanderu ?

Babban manufar shigar da dumama makera quenching workpiece tempering shi ne don rage quenching danniya da kuma kauce wa quenching fasa; wani lokacin, tempering ne don rage taurin saduwa da fasaha bukatun na workpiece.

Akwai kusan hanyoyi guda uku don fushi da kayan aiki bayan kashewa a cikin tanderun dumama induction:

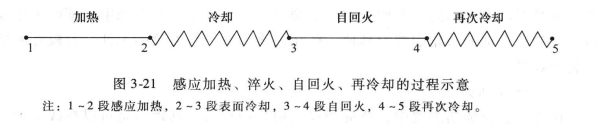

(1) Lokacin da aka kashe aikin mai zafin kai, sanyaya ba ya ci gaba zuwa ƙarshe kuma an katse shi a gaba, don haka sauran zafin da ke kusa da ainihin Layer ɗin da aka taurare an canza shi zuwa Layer mai taurare, don taurare. Layer yana sake yin zafi don isa wani yanayin zafi. Yi Layer mai tauri ya sami tsarin da ake buƙata da aikin da ake buƙata. An yi amfani da wannan hanyar don kashe kuturun kayan aiki da titin ƙarfe a farkon zamanin.

A cikin tsohuwar Tarayyar Soviet a farkon karni na 20, shekaru 50, an fara amfani da su injin wuta taurare workpieces, kamar crank jarida, a gear, da dama fil da sauran auto sassa, da tsari za a iya amfani da a cikin FIG. 3-21 zuwa FIG.

A wasu matakai na zafin kai, matakai na 4 zuwa 5 ana sanyaya su ta hanyar fesa ruwa kuma, yayin da mafi yawan zafin kai, matakai 4 zuwa 5 suna ba da damar aikin aikin ya yi sanyi a cikin iska.

Amfanin tsarin zafin jiki shine cewa yana adana saitin kayan aikin zafi. Ɗauki jaridar crankshaft quenching a matsayin misali. Saboda karɓar wannan tsari a cikin masana’antar kera motoci, an ajiye murhun wuta mai ƙarfi tare da ikon 100kW da yanki na samarwa na 30m 2 akan layin samarwa. Bugu da kari, yana adana wutar lantarki da kuma kula da farashin. Duk da haka, tsarin zafin kai shima yana da gazawa, don haka aikace-aikacen sa yana da iyaka.

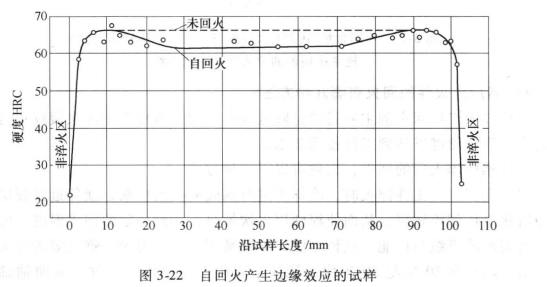

1) Tsarin zafin jiki kawai ya dace da workpieces tare da isasshen zafi mai saura a cikin ainihin kayan aikin bayan dumama, kuma sauran canjin zafi zuwa duk maki na Layer Layer yakamata ya zama uniform; in ba haka ba, da taurin da quenched surface na workpiece ne m bayan kai tempering , Kuma ko da mutum yankunan ba su da kai. Misali, bayan dumama guda daya da kashe kayan zoben zobe na mota, ana buƙatar 48-56HRC. Ana amfani da zafin kai don samun sakamako mai kyau. Yanayin zafin kai na kowane bangare na zoben kayan aiki iri ɗaya ne. Duk da haka, lokacin da aka kashe mujallar crankshaft, abin da ake kira tasirin gefen ya bayyana a kan babban jarida na tsakiya da kuma babban jarida a gefen flange, wato, zafin jiki mai zafi na tsakiyar sashin jarida yana da girma; kuma wurin sauyawa a bangarorin biyu yana kusa da crank. Yana dumama karfe kuma yana watsar da zafi da sauri, kuma yanayin zafin kai yana da ƙasa. Sabili da haka, taurin sashin tsakiya na gabaɗayan sashe yana da ɗan ƙaramin ƙarfi, yayin da ƙarfin juzu’i na sassan juzu’i a bangarorin biyu yana da inganci. Wannan sashe shine yankin damuwa na jujjuyawa kuma shine ya fi saurin kashe fashewa.

Ana iya kwatanta tasirin gefen a cikin Hoto 3-22. Halin zafin kai a tsakiyar sashin samfurin yana da kyau, kuma tasiri a bangarorin biyu ba shi da kyau, yana haifar da bambancin taurin kusan 5HRC. Gwaje-gwaje sun tabbatar da cewa zafin kai ya dace da dumama kayan aiki tare da babban diamita da babban ƙarfin zafi, wato, d>m, tare da ingantaccen yanayin zafi. Bai dace da hanyoyin dumama zafin zafi da kayan aiki tare da ƙananan diamita da ƙananan zafi ba.

2) Wata babbar fa’ida ta tsarin zafin rai shine lokacinsa. Kamar yadda muka sani, shigowa dumama tanderu quenching workpieces gabaɗaya yana buƙatar zafin lokaci don hana fasa kafin zafin rai. A cikin aikin samar da zafin jiki, an tabbatar da cewa saboda lokacin da ake yin zafi, yana da tasiri mai kyau na hana fashewar cam na camshaft da sauran kayan aikin da ke da wuyar fashewa kafin zafin jiki. ”

2) Wata babbar fa’ida ta tsarin zafin rai shine lokacinsa. Kamar yadda muka sani, shigowa dumama tanderu quenching workpieces gabaɗaya yana buƙatar zafin lokaci don hana fasa kafin zafin rai. A cikin aikin samar da zafin jiki, an tabbatar da cewa saboda lokacin da ake yin zafi, yana da tasiri mai kyau na hana fashewar cam na camshaft da sauran kayan aikin da ke da wuyar fashewa kafin zafin jiki. ”

(2) Zazzabi na induction dumama tanderun

A cikin na’urorin dumama induction dumama tanderu na zamani, aikace-aikacen dumama tanderun zafin jiki yana faɗaɗa kowace rana. Dalili kuwa shi ne, ana iya samar da shi a kan layi, a gajarta tsarin samarwa, da kuma magance wasu matsalolin da ba za a iya magance su ta hanyar son kai ba.

Induction dumama tanderu yana da sauƙi, ana iya samar da shi akan layi, kuma yana warware rashin amfani na zafin kai, kamar tasirin gefen, kuma ana amfani dashi a samarwa na zamani. Gabaɗaya akwai hanyoyi guda biyu don husatar da tanderun dumama induction:

1) ta amfani da asali quench dumama samar da wutar lantarki, asali induction dumama makera, na’urar sanye take da wata hanya don rage wuta. shigowa dumama tanderu fushi. Amfanin wannan hanyar ita ce, ana kammala aikin kashe wuta da zafin jiki a lokacin lodawa da saukewa, amma saboda tashar kashe wuta ta mamaye, ana samun raguwa.

Ana amfani da wannan tsari a kan waɗannan ƙananan sassa kamar cranks na babur. Bayan hardening sikanin rabin-axis, 1/5 zuwa 1/6 na matsakaicin mitar wutar lantarki na tsarin kashewa tare da inductor iri ɗaya an yi amfani da shi don yin zafi a cikin tanderun induction induction. Rashin hasara shi ne cewa ana amfani da wutar lantarki ta asali na kashe wutar lantarki a cikin yanayin ƙarancin zafin jiki, kuma mitar sa na yanzu dole ne ya fi na al’ada. Sabili da haka, yanayin zafi na Layer mai taurara ya dogara gaba ɗaya akan yanayin zafi, kuma ƙarancin zafinsa yana da ƙasa.

2) Yi amfani da wani saitin samar da wutar lantarki mai ƙarancin mitar da ya dace da inductor don fushi, kuma ana amfani da wannan hanyar a yanzu. Saboda zafin jiki na induction dumama tanderun da aka kashe sassan ya yi ƙasa da ma’aunin Curie, kuma yawancinsu sun yi ƙasa da 300 ℃, a wannan lokacin, zurfin shigar azzakarinsa a ƙananan zafin jiki sau da yawa shine 1/10 na zurfin shigar yanzu a 800. ℃ ~ 1/4 . Saboda haka, na yanzu mita zaba domin tempering da workpiece ne da yawa m fiye da na yanzu mita a lokacin quenching da dumama. Yana da al’ada don amfani da 1000 ~ 4000Hz, wasu kuma suna amfani da mitar wuta kai tsaye, irin su silinda liners da flywheel zobe gears.

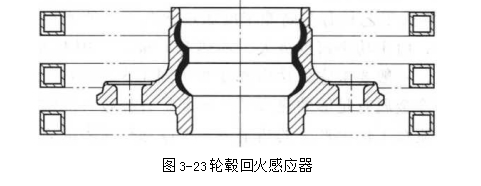

Tempering inductors gabaɗaya suna amfani da juyi da yawa, rata tsakanin zobe mai tasiri da aikin aikin yana haɓaka, kuma yanki na ɓangaren zafin yakan girma fiye da yankin da aka kashe. Na’urar hasashe Hub , kamar yadda aka nuna a hoto 3.23 .

Lokacin da rabin-shaft ɗin ya karɓi aikin dubawa na quenching, yanayin zafinsa kuma yana jin daɗin tanderun dumama. A wannan lokacin, ana amfani da wani ƙaramin tushen wutar lantarki kuma ana amfani da inductor mai juyawa da yawa don dumama da zafi sau ɗaya.

3) Amfanin induction dumama makera tempering:

① Short dumama lokaci, high yawan aiki, shigar da dumama makera low zazzabi tempering dumama kudi ne 4 ~ 2 (H: / s, matsakaici da kuma high zafin jiki tempering dumama kudi ne 5 ~ 30Y / s, Silinda liner yana amfani da ikon mita tempering, 3 guda a lokaci, 220 ℃ lokacin zafi shine 30 ~ 40s.

② Ana iya samun kwanciyar hankali kuma mafi kyawun kayan aikin injiniya.