- 12

- Aug

Yiziphi izindlela zokuthulisa izingxenye ezicishiwe zesithando sokushisa esingeniswayo?

Yiziphi izindlela zokuthambisa izingxenye ezicishiwe ze isithando sokushisa sangaphakathi ?

Inhloso eyinhloko ye-induction yokushisa isithando somlilo ukucisha i-workpiece tempering ukunciphisa ukucindezeleka kokucisha futhi ugweme ukuqhekeka kokucisha; ngezinye izikhathi, tempering iwukuba ukunciphisa ubulukhuni ukuhlangabezana nezidingo zobuchwepheshe of the workpiece.

Cishe kunezindlela ezintathu zokuthulisa ucezu lomsebenzi ngemuva kokucisha isithando somlilo sokungeniswa :

(1) Lapho i-workpiece yokuzikhukhumeza ivaliwe, ukupholisa akuqhubeki kuze kube sekugcineni futhi kuphazamiseke kusengaphambili, ukuze ukushisa okusele okuseduze nomgogodla wengqimba eqinile kudluliselwe kungqimba oluqinile, ukuze ukuqina okuqinile. ungqimba luyashisisa futhi ukuze kufinyelele izinga lokushisa elithile lokuzolisa. Yenza isendlalelo esiqinile sithole isakhiwo esidingekayo nokusebenza. Le ndlela yayisetshenziselwa ukucisha amashizolo amathuluzi nezinsimbi zensimbi ezinsukwini zakuqala.

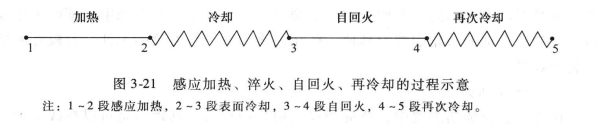

Ezweni elaliyiSoviet Union ekuqaleni kwekhulu lama-20, iminyaka engu-50, yaqala ukusetshenziswa ukufakwa kwesithando somlilo ama-workpieces aqinile, njengejenali ye-crank, igiya, inani lamaphini nezinye izingxenye zezimoto, inqubo ingasetshenziswa ku-FIG. 3-21 kuya ku-FIG.

Kwezinye izinqubo zokuzithiba, izigaba 4 kuya ku-5 zipholiswa ngokufafaza amanzi futhi, kuyilapho ukuzithiba okuningi, izigaba 4 kuya ku-5 zivumela umsebenzi wokusebenza ukuthi uphole ngokwemvelo emoyeni.

Inzuzo yenqubo yokuzithiba ukuthi igcina isethi yemishini yokushisa. Thatha ijenali ye-crankshaft njengesibonelo. Ngenxa yokwamukelwa kwale nqubo endaweni yokukhiqiza izimoto, isithando somlilo esishisayo esinamandla angu-100kW kanye nendawo yokukhiqiza engu-30m 2 zigcinwa emgqeni wokukhiqiza. Ngaphezu kwalokho, yonga izindleko zikagesi kanye nokuwunakekela. Kodwa-ke, inqubo yokuzikhukhumeza nayo inokushiyeka, ngakho-ke ukusetshenziswa kwayo kunomkhawulo.

I-1 ) Inqubo yokuzikhukhumeza ifaneleka kuphela kuma-workpieces anokushisa okwanele okwanele emgodleni we-workpiece ngemva kokushisa, futhi ukudluliselwa kokushisa okusele kuwo wonke amaphuzu ongqimba oluqinile kufanele kube iyunifomu; ngaphandle kwalokho, ubulukhuni bobuso obucishiwe bomsebenzi wokusebenza abuhambisani ngemva kokuzithiba , Futhi ngisho nezindawo zomuntu ngamunye azizithinti. Isibonelo, ngemva kokushisisa okukodwa nokucisha kwegiya leringi yemoto, i-48-56HRC iyadingeka. Ukuzithiba kusetshenziselwa ukuzuza imiphumela emihle. Izinga lokushisa elizibambayo lengxenye ngayinye yeringi yegiya lifana. Kodwa-ke, lapho ijenali ye-crankshaft icinywa, lokho okubizwa ngokuthi umphumela onqenqemeni kuvela kujenali eyinhloko emaphakathi kanye nephephabhuku eliyinhloko ohlangothini lwe-flange, okungukuthi, izinga lokushisa elizibambayo lengxenye ephakathi yephephabhuku liphezulu; futhi indawo yoguquko nhlangothi zombili iseduze ne-crank. Ishisisa insimbi futhi ikhiphe ukushisa ngokushesha, futhi izinga lokushisa lokuzibamba liphansi. Ngakho-ke, ukuqina kwesigaba esiphakathi saso sonke isigaba siphansi, kuyilapho ukuqina kwezigaba zokuguqulwa ezinhlangothini zombili kuphakeme kakhulu. Lesi sigaba siyindawo yengcindezi eqinile futhi ijwayele ukucisha imifantu.

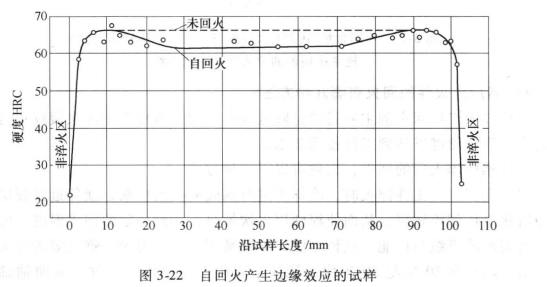

Umphumela onqenqemeni ungaboniswa kuMfanekiso 3-22. Umthelela wokuzithiba esigabeni esimaphakathi sesampula muhle, futhi umphumela kuzo zombili izinhlangothi mubi, okuholela kumehluko wobulukhuni obungaba ngu-5HRC. Ukuhlolwa kufakazele ukuthi ukuzithiba kulungele ukushisisa ama-workpieces anobubanzi obukhulu nomthamo omkhulu wokushisa, okungukuthi, d>m, ngokusebenza kahle okuphezulu kokushisa. Ayilungele izindlela zokushisa zokwenziwa kokushisa kanye nezinto zokusebenza ezinobubanzi obuncane kanye nokushisa okuyisisekelo okuncane kakhulu.

I-2 ) Enye inzuzo enkulu yenqubo yokuzithiba ukuhamba kwayo ngesikhathi. Njengoba sonke sazi, isithando sokushisa sangaphakathi ukucisha ama-workpieces ngokuvamile kudinga ukushisa okufika ngesikhathi ukuvimbela imifantu ngaphambi kokushisa. Emkhiqizweni wokukhiqiza wokuzithiba, kufakazelwa ukuthi ngenxa yokushisa okufika ngesikhathi, kunomphumela ongcono wokuvimbela ukuqhekeka kwekhamera ye-camshaft nezinye izinto zokusebenza ezivame ukuqhekeka ngaphambi kokushisa. ”

I-2 ) Enye inzuzo enkulu yenqubo yokuzithiba ukuhamba kwayo ngesikhathi. Njengoba sonke sazi, isithando sokushisa sangaphakathi ukucisha ama-workpieces ngokuvamile kudinga ukushisa okufika ngesikhathi ukuvimbela imifantu ngaphambi kokushisa. Emkhiqizweni wokukhiqiza wokuzithiba, kufakazelwa ukuthi ngenxa yokushisa okufika ngesikhathi, kunomphumela ongcono wokuvimbela ukuqhekeka kwekhamera ye-camshaft nezinye izinto zokusebenza ezivame ukuqhekeka ngaphambi kokushisa. ”

(2) Ukushisisa kwesithando somlilo sokungeniswa

Emishinini yokushisa isithando somlilo we-induction yesimanje, ukusetshenziswa kokushisa kwesithando somlilo we-induction kuyanda usuku nosuku. Isizathu siwukuthi ingakhiqizwa ku-inthanethi, ifinyeze umjikelezo wokukhiqiza, futhi ilungise ubunzima obungenakuxazululeka ngokuzithiba.

Ukushisa kwesithando sokushisa kwe-induction kulula, kungakhiqizwa ku-inthanethi, futhi kuxazulule ububi bokuzithoba, njengomphumela onqenqemeni, futhi kusetshenziselwa ukukhiqizwa kwesimanje. Ngokuvamile kunezindlela ezimbili zokuthulisa isithando sokushisa esingeniswayo:

I-1) usebenzisa amandla okushisa okuqala okucisha, isithando somlilo sokuqala sokushisa, idivayisi ifakwe indlela yokunciphisa amandla isithando sokushisa sangaphakathi ukuthukuthela. Inzuzo yale ndlela ukuthi inqubo yokucisha nokushisa igcwaliswa ekulayishweni okukodwa nokulayishwa, kodwa ngenxa yokuthi isiteshi sokucisha simatasa, ukukhiqiza kuyancipha.

Le nqubo isetshenziswa kulezi zingxenye ezincane ezifana nama-cranks wesithuthuthu. Ngemuva kokuqina kokuskena kwe-half-axis, u-1/5 kuya ku-1/6 wevolthi yefrikhwensi emaphakathi yenqubo yokucisha nge-inductor efanayo yasetshenziselwa ukushisa esithandweni sokushisa esingeniswayo sokuskena. Okubi ukuthi amandla okuqala okushisa okucisha asetshenziswa esimweni sokushisa esiphansi, futhi imvamisa yakhona yamanje kufanele ibe phezulu kunemvamisa evamile. Ngakho-ke, ukufudumala kwesendlalelo esiqinile kuncike ngokuphelele ekuqhubeni ukushisa, futhi ukusebenza kahle kwayo kokushisa kuphansi.

2) Sebenzisa enye isethi yamandla aphansi asezingeni eliphansi kanye ne-inductor ukuze unciphise, futhi le ndlela isetshenziswa kabanzi manje. Ngenxa yokuthi izinga lokushisa elifudumele lezingxenye ezicishiwe zesithando somlilo sokungeniswa liphansi kunephuzu leCurie, futhi iningi lazo lingaphansi kuka-300 ℃, ngalesi sikhathi, ukujula kokungena kwamanje ekushiseni okuphansi kuvame ukuba ngu-1/10 wokujula kokungena kwamanje ku-800. ℃ ~ 1/4 . Ngakho-ke, imvamisa yamanje ekhethiwe yokuthambisa i-workpiece iphansi kakhulu kunemvamisa yamanje ngesikhathi sokucisha nokushisa. Kuyinto evamile ukusebenzisa i-1000 ~ 4000Hz, futhi abanye basebenzisa ngokuqondile imvamisa yamandla, njengama-cylinder liner namagiya eringi ye-flywheel.

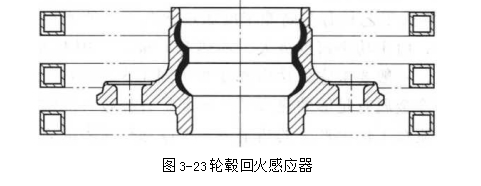

Ama-inductors ashisayo ngokuvamile asebenzisa ukujika okuningi, igebe phakathi kwendandatho esebenzayo kanye nendawo yokusebenza liyakhuliswa, futhi indawo yengxenye epholile ivamise ukuba nkulu kunendawo ecishiwe. Inzwa yokushisa yehabhu , njengoba kukhonjisiwe kuMfanekiso 3.23 .

Lapho i-semi-shaft ithatha inqubo yokucisha ukuskena, ukufutheka kwayo kuphinde kuthuliswe isithando somlilo esingeniswayo . Ngalesi sikhathi, kusetshenziswa omunye umthombo wamandla wefrikhwensi ephansi futhi i-multi-turn inductor isetshenziselwa ukufudumeza nokufudumeza kanye.

3) Izinzuzo zokufudumeza kwesithando somlilo wokungenisa induction:

① Isikhathi esifushane sokushisisa, ukukhiqiza okuphezulu, izinga lokushisa eliphansi lokufudumeza izinga lokushisa elingu-4~2 (H : /s, izinga lokushisa eliphakathi nendawo neliphezulu ngu-5~30Y/s, isilinda liner sisebenzisa ukufudumeza kwefrikhwensi yamandla, izingcezu ezi-3 isikhathi , 220 ℃ Isikhathi sokushisa singama 30 ~ 40s.

② Izakhiwo eziqinile nezingcono zemishini zingatholakala.