- 12

- Aug

Dab tsi yog cov txheej txheem rau tempering quenched qhov chaw ntawm induction cua sov rauv?

Dab tsi yog cov txheej txheem rau tempering quenched qhov chaw ntawm induction cua sov cua sov ?

Lub hom phiaj tseem ceeb ntawm induction cua sov rauv quenching workpiece tempering yog kom txo cov quenching kev nyuaj siab thiab tsis txhob quenching tawg; Qee zaum, tempering yog txo qhov hardness kom tau raws li cov kev cai ntawm lub workpiece.

Muaj kwv yees peb txoj hauv kev kom npau taws rau lub workpiece tom qab quenching nyob rau hauv ib qho induction cua sov rauv:

(1) Thaum tus kheej-tempering workpiece yog quenched, qhov txias tsis mus rau qhov kawg thiab cuam tshuam ua ntej, yog li ntawd cov residual cua sov uas nyob ib sab mus rau lub hauv paus ntawm hardened txheej yog pauv mus rau lub hardened txheej, yog li ntawd lub hardened. txheej yog rhuab dua kom ncav cuag ib yam tempering kub. Ua kom cov txheej tawv tawv tau txais cov qauv tsim nyog thiab kev ua haujlwm zoo. Txoj kev no tau siv rau quenching ntawm cov cuab yeej chisels thiab steel rails nyob rau hauv thaum ntxov hnub.

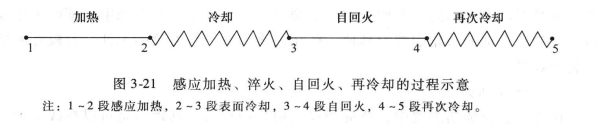

Nyob rau hauv lub qub Soviet Union thaum ntxov 20 xyoo pua, 50 xyoo, pib siv induction taws hardened workpieces, xws li crank journal, ib lub iav, ib tug xov tooj ntawm pins thiab lwm yam pib qhov chaw, cov txheej txheem yuav siv tau nyob rau hauv FIG. 3-21 : kuv.

Hauv qee cov txheej txheem ntawm tus kheej-tempering, theem 4 txog 5 yog txias los ntawm txau dej dua, thaum nyob rau hauv feem ntau tus kheej-tempering, theem 4 mus rau 5 tso cai rau lub workpiece kom txias nyob rau hauv cov huab cua.

Qhov kom zoo dua ntawm tus kheej-tempering txheej txheem yog tias nws txuag cov txheej txheem tempering. Siv cov ntawv xov xwm crankshaft quenching ua piv txwv. Vim qhov kev saws me nyuam ntawm cov txheej txheem no nyob rau hauv ib qho chaw tsim khoom ntawm lub tsheb, lub tshuab hluav taws xob tempering nrog lub zog ntawm 100kW thiab thaj tsam ntawm 30m 2 tau txais kev cawmdim ntawm cov kab ntau lawm. Tsis tas li ntawd, nws txuag hluav taws xob thiab kho cov nqi. Txawm li cas los xij, tus kheej-tempering txheej txheem kuj muaj qhov tsis txaus, yog li nws daim ntawv thov raug txwv.

1) Tus kheej-tempering txheej txheem tsuas yog tsim nyog rau workpieces nrog txaus residual tshav kub nyob rau hauv lub hauv paus ntawm lub workpiece tom qab cua sov, thiab cov residual tshav kub hloov mus rau tag nrho cov ntsiab lus ntawm hardened txheej yuav tsum uniform; txwv tsis pub, lub hardness ntawm quenched nto ntawm lub workpiece yog inconsistent tom qab nws tus kheej-tempering, Thiab txawm ib tug neeg qhov chaw tsis yog tus kheej-tempered. Piv txwv li, tom qab ib qho cua sov thiab quenching ntawm lub tsheb flywheel nplhaib iav, 48-56HRC yuav tsum tau. Self-tempering yog siv los ua kom tau zoo. Tus kheej-tempering kub ntawm txhua feem ntawm lub nplhaib iav yog ib yam. Txawm li cas los xij, thaum lub crankshaft phau ntawv xov xwm raug quenched, lub thiaj li hu ua ntug nyhuv tshwm nyob rau hauv nruab nrab lub ntsiab phau ntawv journal thiab lub ntsiab phau ntawv journal nyob rau sab flange, uas yog, tus kheej-tempering kub ntawm nruab nrab seem ntawm phau ntawv journal yog siab; thiab qhov chaw hloov pauv ntawm ob sab yog ze rau lub crank. Nws heats hlau thiab dissipates tshav kub sai, thiab tus kheej-tempering kub yog tsawg. Yog li ntawd, lub hardness ntawm nruab nrab seem ntawm tag nrho cov seem yog tsawg, thaum lub hardness ntawm cov hloov seem ntawm ob sab yog kuj siab. Ntu no yog thaj tsam tensile kev nyuaj siab thiab yog qhov feem ntau ua rau quenching tawg.

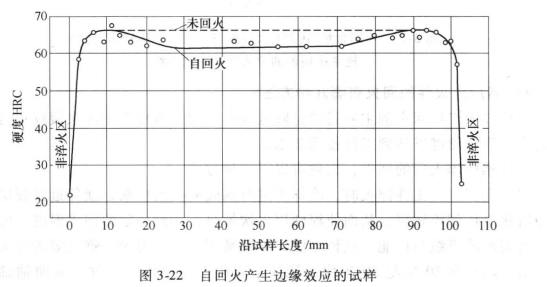

Cov nyhuv ntug tuaj yeem pom hauv daim duab 3-22. Tus kheej-tempering nyhuv nyob rau hauv nruab nrab seem ntawm tus qauv yog zoo, thiab cov nyhuv ntawm ob sab yog tsis zoo, ua rau ib tug hardness sib txawv ntawm txog 5HRC. Cov kev ntsuam xyuas tau ua pov thawj tias nws tus kheej tempering yog tsim rau cua sov workpieces nrog loj txoj kab uas hla thiab loj tshav kub muaj peev xwm, uas yog, d> m, nrog high thermal efficiency. Nws tsis haum rau kev siv hluav taws xob hluav taws xob cua sov thiab cov khoom ua haujlwm nrog cov kab me me thiab cov tub ntxhais me me dhau los.

2) Lwm qhov txiaj ntsig tseem ceeb ntawm tus kheej-tempering txheej txheem yog nws lub sijhawm. Raws li peb txhua tus paub, induction cua sov cua sov quenching workpieces feem ntau yuav tsum tau tempering raws sij hawm kom tsis txhob tawg ua ntej tempering. Hauv kev xyaum ua tus kheej-tempering, nws tau ua pov thawj tias vim lub sijhawm tempering, nws muaj qhov zoo dua ntawm kev tiv thaiv kev tawg ntawm lub camshaft thiab lwm yam khoom ua haujlwm uas ua rau tawg ua ntej tempering. ”

2) Lwm qhov txiaj ntsig tseem ceeb ntawm tus kheej-tempering txheej txheem yog nws lub sijhawm. Raws li peb txhua tus paub, induction cua sov cua sov quenching workpieces feem ntau yuav tsum tau tempering raws sij hawm kom tsis txhob tawg ua ntej tempering. Hauv kev xyaum ua tus kheej-tempering, nws tau ua pov thawj tias vim lub sijhawm tempering, nws muaj qhov zoo dua ntawm kev tiv thaiv kev tawg ntawm lub camshaft thiab lwm yam khoom ua haujlwm uas ua rau tawg ua ntej tempering. ”

(2) Tempering ntawm induction cua sov rauv

Nyob rau hauv niaj hnub induction cua sov rauv cua sov cov cuab yeej, daim ntawv thov ntawm induction cua sov rauv tempering yog nthuav nyob rau hauv ib hnub twg. Yog vim li cas yog tias nws tuaj yeem tsim tawm hauv online, ua kom lub voj voog luv luv, thiab ua rau qee qhov teeb meem uas tsis tuaj yeem daws tau los ntawm tus kheej-tempering.

Induction cua sov rauv tempering yog qhov yooj yim, tuaj yeem tsim hauv online, thiab daws qhov tsis zoo ntawm tus kheej tempering, xws li cov nyhuv ntug, thiab siv nyob rau hauv niaj hnub ntau lawm. Feem ntau muaj ob txoj hauv kev kom npau taws rau qhov cua sov induction:

1) siv cov thawj quench cua sov fais fab mov, thawj induction cua sov rauv, cov cuab yeej nruab nrog ib txoj kev los txo hwj chim. induction cua sov cua sov tempering. Qhov kom zoo dua ntawm txoj kev no yog tias cov txheej txheem quenching thiab tempering tau ua tiav hauv ib qho kev thauj khoom thiab tshem tawm, tab sis vim tias qhov chaw nres tsheb quenching nyob, cov khoom tsim tau raug txo.

Cov txheej txheem no yog siv rau cov khoom me me xws li maus taus cranks. Tom qab ib nrab-axis scanning hardening, 1/5 mus rau 1/6 ntawm qhov nruab nrab zaus voltage ntawm cov txheej txheem quenching nrog tib inductor tau siv rau tempering nyob rau hauv ib tug scanning induction cua sov rauv. Qhov tsis zoo yog qhov qub quenching cua sov fais fab mov yog siv nyob rau hauv qhov kub thiab txias txias, thiab nws cov zaus tam sim no yuav tsum siab tshaj qhov zaus. Yog li ntawd, lub tempering ntawm hardened txheej nyob ntawm tag nrho cov thermal conduction, thiab nws thermal efficiency yog tsawg.

2) Siv lwm txheej uas tsim nyog qis zaus fais fab mov thiab inductor rau tempering, thiab txoj kev no tau siv dav tam sim no. Vim tias qhov kub ntawm qhov kub ntawm induction cua sov rauv quenched qhov chaw qis dua qhov Curie point, thiab feem ntau ntawm lawv qis dua 300 ℃, nyob rau lub sijhawm no, qhov nkag mus rau qhov tob tam sim no ntawm qhov kub qis feem ntau yog 1/10 ntawm qhov tob tob tob ntawm 800. ℃ ~ 1/4 . Yog li, tam sim no zaus xaiv rau tempering lub workpiece yog tsawg dua qhov zaus tam sim no thaum quenching thiab cua sov. Nws yog kev cai siv 1000 ~ 4000Hz, thiab qee qhov ncaj qha siv lub zog zaus, xws li lub tog raj kheej liner thiab flywheel nplhaib iav.

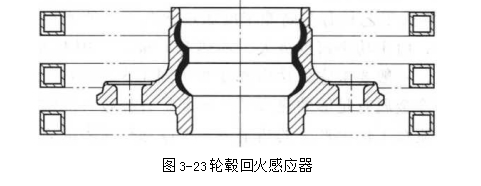

Tempering inductors feem ntau siv ntau qhov lem, qhov sib txawv ntawm lub nplhaib zoo thiab cov khoom ua haujlwm yog loj, thiab thaj tsam ntawm qhov tempered feem ntau loj dua qhov chaw quenched. Hub tempering sensor, raws li qhia hauv daim duab 3.23.

Thaum lub semi-shaft txais cov txheej txheem scanning quenching, nws tempering kuj yog tempered los ntawm induction cua sov rauv. Lub sijhawm no, lwm qhov chaw siv hluav taws xob qis dua yog siv thiab ntau lub tshuab tig inductor yog siv rau cua sov thiab tempering ib zaug.

3) Qhov zoo ntawm induction cua sov rauv tempering:

① Lub sijhawm cua sov luv, kev tsim khoom siab, induction cua sov rauv qhov kub thiab txias yog 4 ~ 2 (H : / s, nruab nrab thiab kub kub tempering cua sov yog 5 ~ 30Y / s, lub tog raj kheej liner siv lub zog zaus tempering, 3 daim ntawm ib lub sij hawm, 220 ℃ Tempering lub sij hawm yog 30 ~ 40s.

② ruaj khov thiab zoo dua txhua yam khoom tuaj yeem tau txais.