- 12

- Aug

Zeziphi iindlela zokufudumeza iindawo ezicinyiweyo zesithando sokufudumala se-induction?

Ziziphi iindlela zokuthambisa iinxalenye ezicinyiweyo ze ukufudumeza iziko ?

Eyona njongo iphambili yokufudumeza i-furnace yokucima i-workpiece tempering kukunciphisa uxinzelelo lokucima kunye nokuphepha ukucima iintanda; ngamanye amaxesha, tempering kukunciphisa ubulukhuni ukuhlangabezana neemfuno zobugcisa workpiece.

Kukho malunga neendlela ezintathu zokufudumeza isixhobo somsebenzi emva kokucima kwisithando somlilo sokufudumeza:

(1) Xa i-workpiece yokuziphendulela icinyiwe, ukupholisa akuqhubeki ukuya ekupheleni kwaye kuphazamiseke kwangaphambili, ukwenzela ukuba ubushushu obushiyekileyo obusondeleyo kumbindi woluhlu oluqinileyo ludluliselwe kumaleko aqiniweyo, ukwenzela ukuba ubushushu obusele bube bunzima. Umaleko ufudunyezwe kwakhona ukufikelela kwiqondo lobushushu obuthile. Yenza umaleko onzima ufumane isakhiwo esifunekayo kunye nokusebenza. Le ndlela yayisetyenziselwa ukucima iitshizi zesixhobo kunye neentsimbi zentsimbi ngemihla yokuqala.

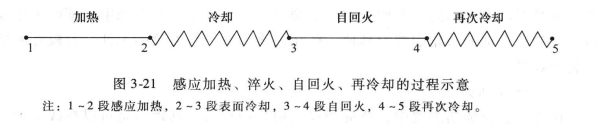

Kwindawo eyayisakuba yiSoviet Union ekuqaleni kwenkulungwane yama-20, iminyaka engama-50 yaqala ukusetyenziswa ityhini izixhobo zokusebenza eziqinileyo, ezifana nejenali yecrank, igiya, inani lezikhonkwane kunye nezinye iindawo zemoto, inkqubo ingasetyenziswa kwiFIG. 3-21 ukuba FIG.

Kwezinye iinkqubo zokuzibamba, inqanaba lesi-4 ukuya kwelesi-5 lipholiswa ngokutshiza amanzi kwakhona, ngelixa uninzi lokuzibamba, inqanaba lesi-4 ukuya kwelesi-5 livumela i-workpiece ukuba iphole ngokwemvelo emoyeni.

Inzuzo yenkqubo yokuzibamba kukuba igcina iseti yezixhobo zokuthambisa. Thatha ijenali yecrankshaft quenching njengomzekelo. Ngenxa yokwamkelwa kwale nkqubo kwiplanti yokuvelisa iimoto, isithando somlilo esinamandla e-100kW kunye nommandla wemveliso we-30m 2 zigcinwa kumgca wemveliso. Ukongeza, igcina iindleko zombane kunye nokugcinwa kwayo. Nangona kunjalo, inkqubo yokuzithoba nayo ineentsilelo, ngoko ke isicelo sayo silinganiselwe.

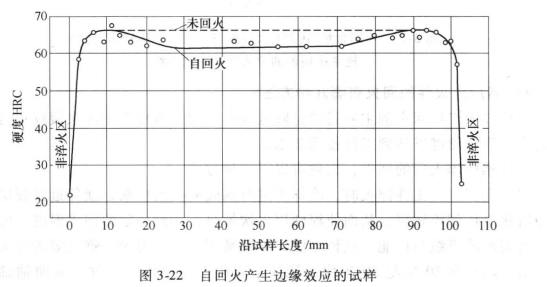

I-1 ) Inkqubo yokuzimela ngokwayo ifaneleka kuphela kwi-workpieces kunye nokufudumala okwaneleyo okushiyekileyo kwi-core of workpiece emva kokufudumeza, kunye nokutshintshwa kokushisa okushiyekileyo kuzo zonke iindawo zoluhlu olunzima kufuneka lufane; ngaphandle koko, ukuqina komphezulu ocinyiweyo we-workpiece ayihambelani emva kokuzibamba , Kwaye neendawo zomntu ngamnye azikwazi ukuzibamba. Umzekelo, emva kokufudumeza okukodwa kunye nokucima igiya leringi yemoto, i-48-56HRC iyafuneka. Ukuzibamba kusetyenziselwa ukufumana iziphumo ezilungileyo. Ubushushu bokuzibamba kwenxalenye nganye yeringi yegiya bufana. Nangona kunjalo, xa ijenali ye-crankshaft icinyiwe, into ebizwa ngokuba yi-edge effect ibonakala kwijenali ephambili ephakathi kunye nejenali ephambili kwicala le-flange, oko kukuthi, ubushushu bokuzibamba kwecandelo eliphakathi kwijenali liphezulu; kwaye indawo yotshintsho kumacala omabini ikufutshane nekranki. Itshisa isinyithi kwaye ikhuphe ukushisa ngokukhawuleza, kwaye ubushushu bokuzibamba buphantsi. Ngako oko, ubunzima becandelo eliphakathi kwecandelo lonke lincinci, ngelixa ubunzima bamacandelo enguqu kumacala omabini buphezulu. Eli candelo lelona candelo loxinzelelo loxinzelelo kwaye lelona lithanda ukucima iintanda.

Umphumo wecala unokubonakaliswa kwi-Figure 3-22. Umphumo wokuzibamba kwinqanaba eliphakathi lesampulu lilungile, kwaye umphumo kumacala omabini awubi, okubangela ukubahluko kobunzima malunga ne-5HRC. Iimvavanyo zibonise ukuba ukuzithobela kukulungele ukufudumeza ii-workpieces ezinobubanzi obukhulu kunye nomthamo omkhulu wokushisa, oko kukuthi, d> m, kunye nokusebenza kakuhle kwe-thermal. Ayifanelekanga iindlela zokufudumeza zokuqhuba ubushushu kunye nezixhobo zokusebenza ezinobubanzi obuncinci kunye nobushushu obuncinci.

2 ) Enye inzuzo enkulu yenkqubo yokuzibamba kukuhamba kwexesha. Njengoko sisazi sonke, ukufudumeza iziko Ukucima i-workpieces ngokubanzi kufuna ukuthambisa kwangexesha ukunqanda iintanda phambi kokuba ubushushu. Kwimveliso ye-self-tempering, kubonakaliswe ukuba ngenxa yokufudumala kwangexesha, kunempembelelo engcono yokuthintela ukukrazula kwekhamera ye-camshaft kunye nezinye izinto zokusebenza ezithandwa kukuqhekeka ngaphambi kokuvutha. ”

2 ) Enye inzuzo enkulu yenkqubo yokuzibamba kukuhamba kwexesha. Njengoko sisazi sonke, ukufudumeza iziko Ukucima i-workpieces ngokubanzi kufuna ukuthambisa kwangexesha ukunqanda iintanda phambi kokuba ubushushu. Kwimveliso ye-self-tempering, kubonakaliswe ukuba ngenxa yokufudumala kwangexesha, kunempembelelo engcono yokuthintela ukukrazula kwekhamera ye-camshaft kunye nezinye izinto zokusebenza ezithandwa kukuqhekeka ngaphambi kokuvutha. ”

(2) Ukufudumeza kwesithando sokufudumala kwe-induction

Kwizixhobo zanamhlanje zokufudumeza isithando somlilo, ukusetyenziswa kwe-induction yokufudumeza isithando somlilo kuyanda imihla ngemihla. Isizathu kukuba inokuveliswa kwi-intanethi, inciphise umjikelo wemveliso, kwaye yenze ubunzima obungenako ukusonjululwa ngokuzibamba.

I-Induction yokufudumeza i-furnace tempering ilula, inokuveliswa kwi-intanethi, kwaye isombulule izinto ezingalunganga zokuzibamba, njengempembelelo edge, kwaye isetyenziselwa imveliso yanamhlanje. Kukho iindlela ezimbini eziqhelekileyo zokufudumeza isithando somlilo sokungenisa:

1) usebenzisa umbane wokufudumeza wokucima umbane wokuqala, isithando somlilo sokuqala, isixhobo sixhotyiswe ngendlela yokunciphisa amandla. ukufudumeza iziko ukucaphuka. Inzuzo yale ndlela kukuba inkqubo yokucima kunye nokufudumala igqityiwe ekulayisheni kunye nokukhulula enye, kodwa ngenxa yokuba isikhululo sokucima sihlala, imveliso iyancitshiswa.

Le nkqubo isetyenziswa kula malungu amancinci afana neekranki zesithuthuthu. Emva kokuqina kwesiqingatha se-axis, i-1/5 ukuya kwi-1/6 ye-voltage ephakathi yenkqubo yokucima kunye ne-inductor efanayo yayisetyenziselwa ukufudumala kwisithando sokufudumala sokufudumala. Ukungalungi kukuba unikezelo lwamandla obushushu okucima loqobo lusetyenziswa kwimeko yobushushu obuphantsi, kwaye isantya salo sangoku kufuneka sibe phezulu kunesiqhelo. Ngoko ke, ukufudumala komgangatho oqinileyo kuxhomekeke ngokupheleleyo ekuqhubeni ukushisa, kwaye ukusebenza kwayo kwe-thermal kuphantsi.

2) Sebenzisa enye iseti yonikezelo lwamandla asezantsi asezantsi kunye ne-inductor yobushushu, kwaye le ndlela isetyenziswa ngokubanzi ngoku. Ngenxa yokuba iqondo lobushushu elifudumeleyo le-induction yokufudumeza iziko elicinyiweyo lisezantsi kunendawo yeCurie, kwaye uninzi lwazo lungaphantsi kwama-300 ℃, ngeli xesha, ubunzulu bokungena ngoku kwiqondo lobushushu obuphantsi buhlala buyi-1/10 yobunzulu bokungena ngoku kwi-800. ℃ ~ 1/4 . Ke ngoko, i-frequency yangoku ekhethiweyo yokuthambisa i-workpiece iphantsi kakhulu kune-frequency yangoku ngexesha lokucima kunye nokufudumeza. Kulisiko ukusebenzisa i-1000 ~ 4000Hz, kwaye abanye basebenzise ngokuthe ngqo ukuphindaphindwa kwamandla, okufana ne-cylinder liners kunye ne-flywheel ring gears.

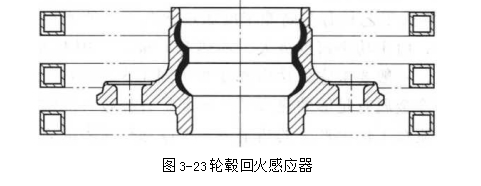

I-Tempering inductors ngokuqhelekileyo isebenzisa ukujika okuphindaphindiweyo, umsantsa phakathi kweringi esebenzayo kunye ne-workpiece yandiswa, kwaye indawo yenxalenye epholileyo ihlala inkulu kunendawo ecinyiweyo. Inzwa ye-Hub tempering, njengoko kubonisiwe kuMfanekiso 3.23.

Xa i-semi-shaft ithatha inkqubo yokucima ukuskena, ukuvutha kwayo kuphinde kuthotywe sisithando sokufudumala somlilo. Ngeli xesha, omnye umthombo wamandla ophantsi ophantsi uyasetyenziswa kwaye i-multi-turn inductor isetyenziselwa ukufudumeza kunye nokufudumeza kube kanye.

3 ) Izinto eziluncedo zokufudumeza isithando somlilo:

① Ixesha elifutshane lokufudumeza, imveliso ephezulu, i-induction yokufudumeza iziko lobushushu eliphantsi lobushushu obuphantsi beqondo lokufudumeza yi-4 ~ 2 (H : / s, iqondo lobushushu eliphakathi kunye neliphezulu lokufudumeza yi-5 ~ 30Y/s, i-cylinder liner isebenzisa ukufudumeza amandla, iziqwenga ezi-3 ixesha , 220 ℃ ixesha Tempering yi 30 ~ 40s .

② Iipropati ezizinzileyo kunye nezingcono zoomatshini zinokufumaneka.