- 12

- Aug

Kedu ụzọ a ga-esi eme ka akụkụ ọkụ induction kpo oku ọkụ?

Gịnị bụ ụzọ nke tempering quenched akụkụ nke induction kpo oku ?

Isi nzube nke induction kpo oku oku ọkụ quenching workpiece tempering bụ ibelata quenching nchegbu ma zere quenching cracks; mgbe ụfọdụ, tempering bụ iji belata ike izute teknuzu chọrọ nke workpiece.

Enwere ụzọ atọ iji kpasuo ihe na-arụ ọrụ ọkụ mgbe ị kwụsịrị n’ime ọkụ ọkụ induction:

(1) Mgbe arụ ọrụ nke na-ewe iwe ọkụ na-emenyụ, oyi anaghị aga n’ihu na njedebe ma kwụsịtụ tupu oge eruo, nke mere na ọkụ fọdụrụ n’akụkụ isi nke oyi akwa siri ike na-ebufe ya na oyi akwa siri ike, nke mere na ihe siri ike. oyi akwa na-ekpo ọkụ ọzọ iru a ụfọdụ tempering okpomọkụ. Mee ka oyi akwa siri ike nweta nhazi na arụmọrụ achọrọ. A na-eji usoro a emenyụ ọkụ nke ngwá ọrụ na okporo ígwè ígwè n’oge mbụ.

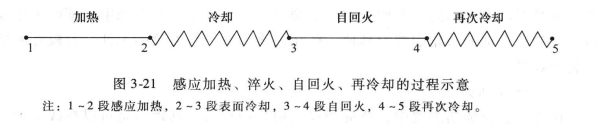

Na mbụ Soviet Union ná mmalite narị afọ 20, afọ 50, malitere iji ọkụ ọkụ ọkụ arụ ọrụ siri ike, dị ka akwụkwọ akụkọ crank, gia, ọtụtụ pin na akụkụ akpaaka ndị ọzọ, enwere ike iji usoro a na FIG. 3-21 ruo FIG.

N’ụfọdụ usoro iwe iwe, usoro 4 ruo 5 na-ajụkwa oyi site na ịfesa mmiri ọzọ, ebe n’ọtụtụ iwe ọkụ, usoro 4 ruo 5 na-ekwe ka workpiece dị jụụ n’ikuku.

Uru nke usoro iwe iwe onwe ya bụ na ọ na-echekwa otu ihe eji eme ihe ọkụ. Were akwụkwọ akụkọ crankshaft quenching dị ka ọmụmaatụ. N’ihi nnabata nke usoro a na ụlọ ọrụ na-emepụta ụgbọ ala, a na-echekwa ọkụ ọkụ na ike nke 100kW na mpaghara mmepụta nke 30m 2 na akara mmepụta. Tụkwasị na nke ahụ, ọ na-echekwa ọkụ eletrik na ụgwọ ọrụ. Otú ọ dị, usoro iwe iwe onwe ya nwekwara adịghị ike, ya mere ngwa ngwa ya dị oke.

1) The onwe-ewe iwe usoro bụ naanị adabara workpieces na zuru ezu ihe fọdụrụ okpomọkụ na isi nke workpiece mgbe kpo oku, na ihe fọdụrụ okpomọkụ nyefe niile isi nke oyi oyi akwa kwesịrị edo; ma ọ bụghị ya, ike nke quenched elu nke workpiece bụ ekwekọghị mgbe onwe-ewe iwe , Na ọbụna onye ebe na-adịghị onwe-ewe iwe. Dịka ọmụmaatụ, mgbe otu kpo oku na imenyụ nke mgbanaka mgbanaka ụgbọ ala, 48-56HRC chọrọ. A na-eji iwe iwe onwe ya mee ihe dị mma. Igwe ọkụ na-ekpo ọkụ nke akụkụ ọ bụla nke mgbanaka gia bụ otu. Otú ọ dị, mgbe akwụkwọ akụkọ crankshaft kwụsịrị, ihe a na-akpọ mmetụta ihu na-apụta n’etiti akwụkwọ akụkọ etiti na akwụkwọ akụkọ dị n’akụkụ flange, ya bụ, okpomọkụ nke onwe ya nke etiti etiti akwụkwọ akụkọ dị elu; na mpaghara mgbanwe n’akụkụ abụọ dị nso na crank. Ọ na-ekpo ọkụ ígwè ma na-ekpochapụ ọkụ ngwa ngwa, na okpomọkụ nke onwe ya dị ala. Ya mere, ike nke etiti etiti nke akụkụ ahụ dum dị ntakịrị, ebe ike nke akụkụ mgbanwe n’akụkụ abụọ dị elu. Nkebi a bụ mpaghara nrụgide tensile na ọ na-adịkarị mfe imenyụ mgbawa.

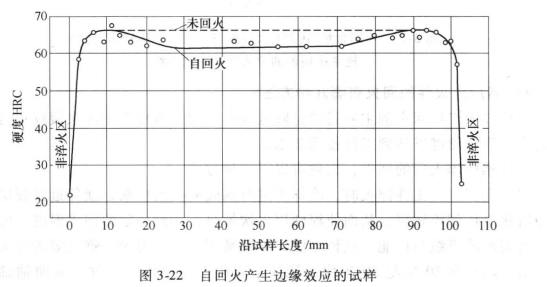

Enwere ike igosi mmetụta ihu na foto 3-22. Mmetụta iwe iwe onwe ya na mpaghara etiti nke ihe nlele ahụ dị mma, na mmetụta dị n’akụkụ abụọ ahụ adịghị mma, na-akpata ọdịiche siri ike nke ihe dịka 5HRC. Nnwale egosila na iwe ọkụ dị mma maka ikpo ọkụ workpieces nwere nnukwu dayameta na nnukwu okpomọkụ, ya bụ, d>m, na-arụ ọrụ nke ọma. Ọ dịghị adabara okpomọkụ conduction ụzọ kpo oku na workpieces na obere dayameta na oke obere isi okpomọkụ.

2) Uru ọzọ dị mkpa nke usoro iwe iwe onwe ya bụ oge ya. Dị ka anyị niile maara, induction kpo oku quenching workpieces n’ozuzu na-achọ n’oge iwe iji gbochie cracks tupu tempering. Na omume mmepụta nke iwe iwe, a gosipụtara na n’ihi iwe ọkụ n’oge, ọ na-enwe mmetụta dị mma nke igbochi mgbawa nke cam nke camshaft na ihe ndị ọzọ na-arụ ọrụ nke na-adịkarị mfe mgbawa tupu iwe ọkụ. ”

2) Uru ọzọ dị mkpa nke usoro iwe iwe onwe ya bụ oge ya. Dị ka anyị niile maara, induction kpo oku quenching workpieces n’ozuzu na-achọ n’oge iwe iji gbochie cracks tupu tempering. Na omume mmepụta nke iwe iwe, a gosipụtara na n’ihi iwe ọkụ n’oge, ọ na-enwe mmetụta dị mma nke igbochi mgbawa nke cam nke camshaft na ihe ndị ọzọ na-arụ ọrụ nke na-adịkarị mfe mgbawa tupu iwe ọkụ. ”

(2) Ọkụ nke induction ọkụ ọkụ

N’ime ngwaọrụ ndị na-ekpo ọkụ ọkụ ọkụ induction ọgbara ọhụrụ, itinye ọkụ ọkụ ọkụ induction na-agbasawanye kwa ụbọchị. Ihe kpatara ya bụ na enwere ike imepụta ya n’ịntanetị, mee ka usoro mmepụta ihe dị mkpụmkpụ, ma dozie ụfọdụ ihe isi ike ndị na-enweghị ike idozi site n’iwe onwe onye.

Igwe ọkụ ọkụ ọkụ induction dị mfe, enwere ike imepụta ya na ntanetị, na-edozikwa adịghị ike nke iwe onwe ya, dị ka mmetụta ihu, ma jiri ya mee ihe n’oge a. Enwere ụzọ abụọ iji kpasuo ọkụ induction ọkụ:

1) site na iji ọkụ ọkụ ọkụ ọkụ mbụ na-ekpo ọkụ, ọkụ ọkụ induction mbụ, ngwaọrụ ahụ nwere ụzọ iji belata ike. induction kpo oku iwe iwe. Uru nke usoro a bụ na a na-emecha usoro nkwụsịtụ na iwe ọkụ n’otu ntinye na nbudata, ma n’ihi na ebe a na-emenyụ ọkụ na-arụ ọrụ, a na-ebelata mmepụta ya.

A na-etinye usoro a na obere akụkụ ndị a dị ka ọgba tum tum. Mgbe ọkara-axis scanning hardening, 1/5 ruo 1/6 nke etiti oge voltaji nke usoro mmenyụ ọkụ na otu inductor ka ejiri mee ihe maka iwe ọkụ na ọkụ ọkụ induction induction. Mwepu bụ na mbụ quenching kpo oku ọkụ na-eji na tempering ala okpomọkụ ọnọdụ, na ya ugbu ugboro ga-adị elu karịa nkịtị ugboro. Ya mere, iwe ọkụ nke oyi akwa siri ike na-adabere kpamkpam na njikwa okpomọkụ, na arụmọrụ okpomọkụ ya dị ala.

2) Jiri ọzọ set nke kwesịrị ekwesị ala ugboro ike ọkọnọ na inductor maka tempering, na usoro a na ọtụtụ-eji ugbu a. N’ihi na tempering okpomọkụ nke induction kpo oku ọkụ quenched akụkụ dị ala karịa Curie point, na ọtụtụ n’ime ha bụ ala karịa 300 ℃ , n’oge a, nke ugbu a penetration omimi na obere okpomọkụ bụ mgbe 1/10 nke ugbu a penetration omimi na 800. ℃ ~ 1/4 . Ya mere, nke ugbu a ugboro ahọrọ maka tempering na workpiece bụ nnọọ ala karịa nke ugbu a ugboro n’oge quenching na kpo oku. Ọ bụ omenala iji 1000 ~ 4000Hz, ụfọdụ na-ejikwa ugboro ugboro, dị ka cylinder liners na flywheel mgbanaka mgbanaka.

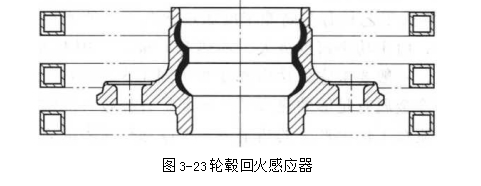

Tempering inductors n’ozuzu na-eji otutu ntụgharị, ọdịiche dị n’etiti mgbanaka dị irè na workpiece na-abawanye, na mpaghara nke akụkụ ahụ na-ewe iwe na-abụkarị ibu karịa ebe a kwụsịrị. Ihe mmetụta tempering Hub, dị ka egosiri na foto 3.23 .

Mgbe ọkara ogwe ahụ na-anabata usoro nyocha nyocha, ọ na-ewekwa iwe ọkụ site na ọkụ ọkụ induction. N’oge a, a na-eji isi iyi ike ọzọ dị ala ma na-eji inductor multi-atụgharị eme ihe maka ikpo ọkụ na iwe ọkụ otu ugboro.

3) Uru nke induction kpo oku ọkụ tempering:

① Short kpo oku oge, elu arụpụtaghị ihe, induction kpo oku oku ala okpomọkụ tempering okpomọkụ ọnụego bụ 4 ~ 2 (H: / s, ọkara na elu okpomọkụ tempering okpomọkụ ọnụego bụ 5 ~ 30Y / s, cylinder liner na-eji ike ugboro tempering, 3 iberibe na oge, 220 ℃ Oge okpomọkụ bụ 30 ~ 40s.

② Enwere ike nweta akụrụngwa siri ike na nke ka mma.