- 07

- Dec

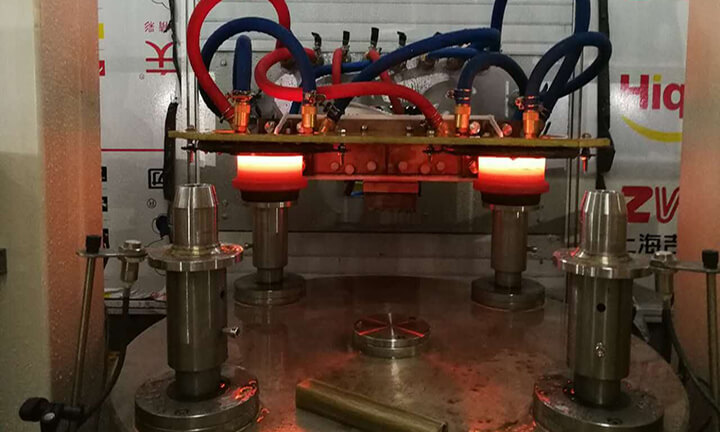

Mochini oa ho tima Mechatronics

Mochini oa ho tima Mechatronics

Ka nts’etsopele e tsoelang pele ea theknoloji ea kalafo ea mocheso oa tšepe, sete e felletseng ea lisebelisoa tsa ho futhumatsa tsa motlakase tsa motlakase li thehile lihlahisoa tse fapaneng le lihlahisoa tsa serialized. Mokhoa oa ts’ebeletso o thehile mokhoa oa boenjiniere oa “turnkey” oa mohato o le mong, mme o file mosebelisi sete ea ts’ebetso e ntle le e tšepahalang, ts’ebetso e bolokehileng le e bonolo, ts’ebetso e phahameng le ho boloka matla, ts’ireletso e nepahetseng ea tikoloho, ho rarahana ha ts’ebetso e phahameng le ho kopanya tlhahisoleseling ho e ‘ngoe, le lisebelisoa tsa ho futhumatsa tsa Mechatronics tsa boleng bo holimo.

Thepa ea ho futhumatsa ea mechatronics e sebelisa k’homphieutha ho laola tlhahiso le tsamaiso ea boleng ba marang-rang, e ka bonang boemo ba mosebetsi, lebelo le tsamaeang, ho futhumatsa, lekhalo, nako ea ho pholisa, matla a ho futhumatsa, ho tima phallo ea mocheso le mocheso, joalo-joalo, le pontsho e felletseng le ho hatisa. Mekhahlelo ea kalafo ea mocheso ea karolo e tšoaroa ka hlooho ‘me e ka khutlisoa neng kapa neng. Thepa e na le li-anti-magnetic, anti-interference, anti-corrosion, likhoerekhoere le lisebelisoa tsa karohano ea metsi a oli. Nakong ea ts’ebetso ea ho tima, palo ea phetoho ea mochine o moholo oa mochine o fihla boemong ba 0mm, ‘me ho nepahala ha reset ea ho sisinyeha ho pheta-pheta ho ka fihla ho 0.0005mm.

Mesebetsi e ka sehloohong ea tsamaiso ea ho laola ka mokhoa o itekanetseng

① Taolo ea ketane: taolo e hokahaneng ea lisebelisoa tsa motlakase tse amehang ka har’a sistimi ho fihlela litlhoko tsa mahlale.

② Taolo ea phallo ea ts’ebetso: Sebelisa maemo a holimo a parameter le mesebetsi ea taolo ea sistimi ena ho ntlafatsa ts’ebetso ea tlhahiso ea mohala oa tlhahiso le ho e ngola tsamaisong. Sebelisa parameter ena ho laola ka ho toba lebelo la ts’ebetso le matla a ho futhumatsa ho finyella papali e ntle ka ho fetisisa pakeng tsa matla a ho futhumatsa le lebelo la ho sebetsa. .

③ Tsamaiso ea ts’ebetso ea tlhahiso: Sistimi e sebelisa ka botlalo bophahamo ba komporo ho boloka likarolo tse fapaneng tsa ho tima komporong, e le hore basebelisi ba ka fokotsa nako ea ho lokisa ha ba fetola lihlahisoa le ho ntlafatsa katleho ea tlhahiso.

④ Tlhokomelo ea tlhahiso: sebelisa sekirini sa mebala ho bonts’a li-curve tse amanang le sistimi, joalo ka ho matha lebelo la mela, voltage, hona joale, matla a behiloeng, mocheso oa mocheso le likarolo tse ling ho futhumatsang.

⑤ Taolo ea data: rekota lintlha tsa nalane, theha polokelo ea litaba, ‘me u boloke le ho laola lits’ebetso tsa ts’ebetso ea basebelisi le maemo a ts’ebetso. Fetolela datha ea nalane hore e be lifaele tsa polokelo, u li fumane ka nako efe kapa efe, ‘me u li bonts’e ka mokhoa o hlakileng, ‘me u etse litlaleho tse fapaneng tsa nako ea nnete.

⑥ Pontšo ea ho shebella alamo: Sebelisana le potoloho ea phepelo ea motlakase, potoloho ea phepelo ea mochini, sistimi e potolohang ea metsi a pholileng le likarolo tse ling ho etsa tlhahlobo e felletseng. Ha ntho efe kapa efe e sa tloaelehang e etsahala potolohong kapa maemo a ts’ebetso a fetoha, mosebelisi a ka potlakela kapa a lla, ‘me mosebelisi a ka etsa ts’ebetso e amanang le eona ho latela molaetsa oa alamo Ho netefatsa hore lisebelisoa li ka sebetsa ka mokhoa o tloaelehileng.

⑦ Ts’ebetso ea marang-rang: Sistimi e ka sebelisa likhomphutha tse ling ho lekola boemo ba ts’ebetso ea sistimi eohle libakeng tse fapaneng.