- 07

- Dec

Umshini Wokucisha we-Mechatronics

Umshini Wokucisha we-Mechatronics

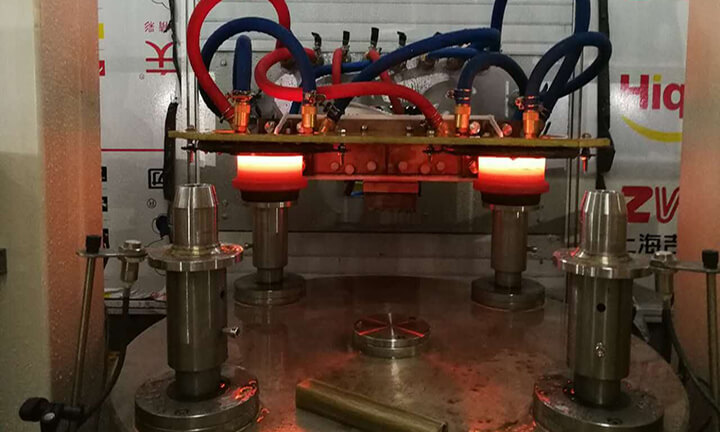

Ngokuthuthuka okuqhubekayo kobuchwepheshe bokwelashwa kokushisa kwensimbi, isethi ephelele yemishini yokushisa yokungeniswa kwe-electromechanical iye yakha imikhiqizo ehlukahlukene kanye nemikhiqizo ye-serialized. Indlela yesevisi isungule indlela yobunjiniyela yesinyathelo esisodwa “turnkey”, futhi yanikeza umsebenzisi isethi yokusebenza okuhle kakhulu nokuthembekile, ukusebenza okuphephile nokulula, ukusebenza kahle okuphezulu nokonga amandla, ukuvikelwa kwemvelo okunembile, inqubo eyinkimbinkimbi kanye nokuhlanganiswa kolwazi eyodwa, kanye nekhwalithi enhle kakhulu yemishini yokushisa yokungeniswa kwe-Mechatronics.

Imishini yokushisa yokungeniswa kwe-mechatronics isebenzisa ikhompuyutha ukulawula ukukhiqizwa kanye nesistimu yokuphatha ikhwalithi ku-inthanethi, engaqapha indawo yokusebenza, isivinini esinyakazayo, ukufudumeza, igebe, isikhathi sokupholisa, amandla okushisa, ukucisha ukugeleza okuphakathi kanye nezinga lokushisa, njll., futhi ukuboniswa okuphelele nokuphrinta. Imingcele yokwelapha ukushisa yengxenye ibanjwa ngekhanda futhi ingalandwa noma kunini. Imishini ine-anti-magnetic, anti-interference, anti-corrosion, indle kanye nezinsiza zokuhlukanisa uwoyela namanzi. Ngesikhathi sokusebenza kokucisha, inani lokuguqulwa kwedrayivu eyinhloko yomshini lifinyelela izinga lika-0mm, futhi ukunemba kokusetha kabusha kokunyakaza okuphindaphindiwe kungafinyelela ku-0.0005mm.

Imisebenzi esemqoka yesistimu yokulawula okuzenzakalelayo

① Ukulawulwa kochungechunge: ukulawulwa kwe-interlock kwezinto zikagesi ezifanele ohlelweni ukuze kuhlangatshezwane nezidingo zobuchwepheshe.

② Ukulawulwa kokugeleza kwenqubo: Sebenzisa ukulungiselelwa kwepharamitha ephakeme kanye nemisebenzi yokulawula yale sistimu ukuze ulungiselele inqubo yokukhiqiza yolayini wokukhiqiza futhi uyirekhode ohlelweni. Sebenzisa le parameter ukuze ulawule ngokuqondile isivinini sokusebenza namandla okushisa ukuze uzuze ukufana okuhle kakhulu phakathi kwamandla okushisa kanye nesivinini sokusebenza. .

③Ukuphathwa kwenqubo yokukhiqiza: Isistimu isebenzisa ngokugcwele ukuphakama kwekhompuyutha ukugcina izingxenye ezahlukahlukene zezinqubo zokucisha kukhompuyutha, ukuze abasebenzisi bakwazi ukwehlisa isikhathi sokulungisa lapho beshintsha imikhiqizo futhi bathuthukise ukusebenza kahle kokukhiqiza.

④ Ukuqapha ukukhiqiza: sebenzisa isikrini sombala ukuze ubonise ngokushintshashintshayo amajika epharamitha ahlobene nesistimu, njengokusebenzisa isivinini somugqa, i-voltage, yamanje, amandla asethiwe, izinga lokushisa lokushisisa namanye amapharamitha ekushisiseni.

⑤Ukuphathwa kwedatha: rekhoda idatha yomlando, sungula imininingo egciniwe esebenzayo, futhi ufake kungobo yomlando futhi ulawule izinqubo zokucubungula umsebenzisi namapharamitha wokucubungula. Guqula idatha yomlando ibe amafayela engobo yomlando, wabuyise nganoma isiphi isikhathi futhi uwabonise ngezithombe, futhi wenze imibiko ehlukahlukene yesikhathi sangempela.

⑥Isibonisi sokuqapha i-alamu: Sebenzisana nesekhethi yokuphakelwa kwamandla, isekethe yokudlulisa ngomshini, isistimu yamanzi okupholisa azungezayo nezinye izingxenye ukuze wenze ukuqapha okuphelele. Uma kwenzeka noma yikuphi ukungahambi kahle kusekethe noma izimo zokusebenza zishintsha, umsebenzisi angazisa noma axwayise, futhi umsebenzisi angakwazi ukwenza ukucubungula okuhlobene ngokuya ngokwaziswa kwe-alamu Ukuqinisekisa ukuthi okokusebenza kungasebenza ngokujwayelekile.

⑦ Umsebenzi wenethiwekhi: Uhlelo lungasebenzisa amanye amakhompyutha ukuqapha isimo sokusebenza salo lonke uhlelo ezindaweni ezahlukene.