- 19

- Aug

Ka’idodin Tsarin Kula da Yanayin Aiki na PLC don Furnace Mai narkewa

Ka’idojin PLC Tsarin Kula da Yanayin Aiki don Rushewar Wuta

Tsarin sa ido na yanayin aiki na PLC na murhun narkewar induction yana haɗuwa tare da allon nuni na 10-inch, tare da ayyuka kamar sarrafawa da daidaitacce, nuni ta atomatik, da ƙwaƙwalwar atomatik.

1. PLC na’ura wasan bidiyo na waje na narke narke tanderun sanye take da DC voltmeter, DC ammeter, matsakaicin mitar voltmeter, matsakaicin mitar mitar, matsakaicin mitar wutar lantarki, kayan aikin nunin zafin jiki, da sauransu. Duk sigogin kayan aiki za’a iya nuna su cikin fahimta. Siemens 10-inch allon taɓawa yana iya saita tanda cikin sauƙi ko tsarin narkewa, kuma yana iya nuna yanayin narkewa da ƙarfin kayan aiki da sauran madaidaitan ma’aunin a ainihin lokacin. An ƙera na’urar wasan bidiyo tare da sauyawar wutar lantarki, jagorar mitar matsakaici da sauyawa ta atomatik, maɓallin dakatar da gaggawa, hasken wutar lantarki, hasken mitar mitar matsakaici da haske mai nuna kuskure.

2. An tsara kwamitin kula da wutar lantarki na tsaka-tsakin tsaka-tsaki tare da yanayin rufewar madauki na zafin jiki. An zaɓi kayan aikin sarrafa zafin jiki daga Japan Island Electric SR3 tare da kayan daidaitawa na PID. An zaɓi ma’aunin zafin jiki mai nisa na fiber na gani daga jerin ma’aunin zafi da sanyio na Optris CT na Jamus, wanda ke auna zafin jiki -40-900°C. Da farko, saita zafin zafin jiki da saurin annealing akan kayan sarrafa zafin jiki ko allon taɓawa na PLC. Bayan an kunna wutar, ma’aunin zafi da sanyio yana auna zafin dumama a ainihin lokacin kuma yana ciyar da shi zuwa kayan sarrafa zafin jiki. Kayan aikin sarrafa zafin jiki yana kwatanta ma’aunin zafin jiki tare da saita zafin jiki na dumama kuma yana fitar da simulation Ana aika siginar zuwa babban allon kula da mitar matsakaici, kuma babban kwamiti yana daidaita kusurwar faɗakarwar thyristor ta atomatik gwargwadon matakin siginar, don haka ana daidaita ƙarfin fitarwa na wutar lantarki tare da matakin siginar analog, cimma maƙasudin sarrafa madauki na zazzabi. Lokacin da aka daidaita saurin ciyar da bututun jan ƙarfe, ma’aunin zafi da sanyio yana gano canjin zafin bututun jan ƙarfe, kuma yana fitar da siginar da ta dace daidai da kwatancen zafin da aka gano da kuma yanayin zafin da aka saita.

Don allon kula da mitar matsakaita, za a daidaita ikon fitarwa na matsakaicin wutar lantarki zuwa wutar da ake buƙata don cimma manufar sarrafa madauki na zazzabi.

CT jerin Optris na musamman ma’aunin zafi da sanyio don auna jan karfe

3. Matsakaicin matsakaicin mitar na’ura mai sarrafawa na waje an tsara shi tare da kullin aiki na manual da atomatik. Lokacin da aka zaɓi yanayin atomatik, kayan aikin suna ɗaukar tsarin sarrafa madauki na zazzabi, kuma ikon kayan aiki yana daidaita ƙarfin fitarwa ta atomatik gwargwadon yanayin zafin narke. An ƙera allon kula da wutar lantarki na tsaka-tsaki tare da rufewar madauki mai sarrafa zafin jiki. Kayan aikin sarrafa zafin jiki ya zaɓi Shimadden SR3 tare da kayan daidaitawa na PID, kuma ma’aunin zafi da sanyio na fiber optic na infrared mai nisa yana zaɓar jerin ma’aunin zafi da sanyio na Optris CT na Jamusanci, kuma zafin jiki shine 385-1600 ℃. Da farko saita zafin narke akan kayan sarrafa zafin jiki ko allon taɓawa na PLC. Bayan an fara samar da wutar lantarki ta tsaka-tsaki, ma’aunin zafi da sanyio yana auna zafin zafin jiki a ainihin lokacin kuma yana ciyar da shi zuwa kayan sarrafa zafin jiki. Kayan aikin sarrafa zafin jiki yana kwatanta yanayin da aka auna tare da saita zafin jiki na dumama sannan ya fitar da siginar analog zuwa IDAN babban kwamiti mai kulawa, babban kwamiti na sarrafawa ta atomatik yana daidaita kusurwar faɗakarwar thyristor gwargwadon matakin siginar, ta yadda ƙarfin fitarwa ya kasance. na wutar lantarki za a iya daidaita shi tare da matakin siginar analog. Lokacin da mai amfani ya zaɓi yanayin aiki da hannu, na’urar tana narkewa a matsakaicin ƙarfin fitarwa.

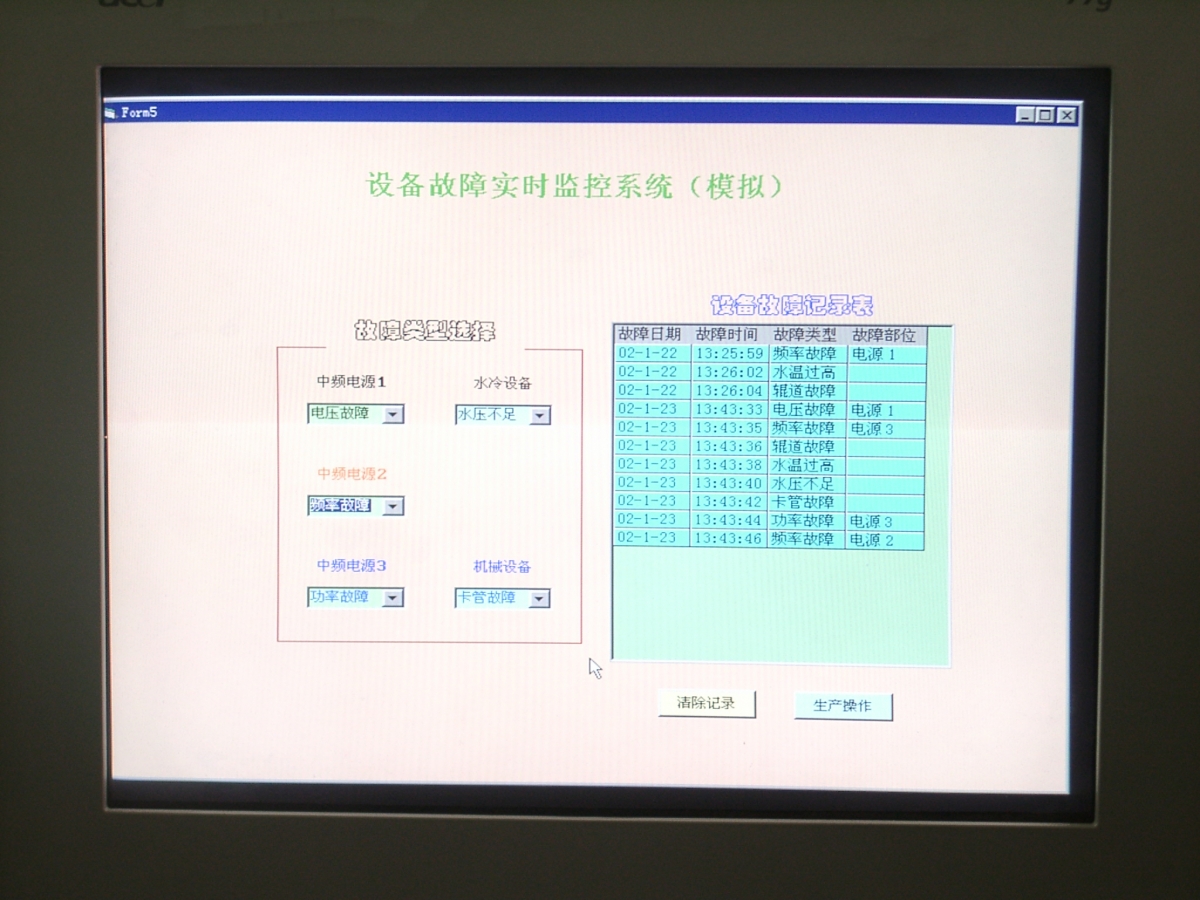

4. Baya ga nuna yanayin aiki na kayan aiki, allon taɓawa zai iya saka idanu akan gazawar kayan aiki da samar da shawarwarin kulawa da sauran bayanai. Jagorar aiki yana tare da hanyoyin aiki na kayan aiki, abubuwan rashin nasara gama gari da hanyoyin jiyya.

IDAN tsarin samar da wutar lantarki PLC kayan aiki na tsarin sa ido yana iya samun ayyuka masu zuwa:

1) Cikakkun ayyukan sarrafa narkewar narkewa, gano kuskuren atomatik, sintering na atomatik da sauran ayyuka. 2) 2) Cikakken aikin sarrafa tsarin narkewa da cikakkiyar kulawa, ƙararrawa da aikin tantance kai na kuskure. 3) 3) Cikakken tsarin ƙararrawa na sauti da haske, wanda zai tsoratar da yanayi masu zuwa:

An buɗe majalisar jujjuyawar mitar;

Capacitor ya lalace;

Yanayin zafi na ruwan sanyi a cikin kowane da’irar wutar lantarki ya yi yawa;

Matsi na ruwa mai sanyaya wutar lantarki ya yi ƙasa sosai;

Yanayin zafin wutar lantarki mai sanyaya ruwa ya yi yawa;

Matsalolin ruwan sanyi na tanderun ya yi ƙasa sosai;

Zaɓin tanderun / keɓancewa ba daidai ba ne;

Sashin gyara na madaidaicin wutar lantarki ba shi da fitowar DC;

Ƙararrawar gano tanderun ƙasa / yoyo.

Sarrafa hukuma da shigarwar rarraba wutar lantarki da fasahar wayoyi:

Babban Sauyawa: Tsarin waya takwas mai waya shida mai shigowa, wato, samar da wutar lantarki mai hawa shida, waya ta ƙasa mai hawa ɗaya, da waya tsaka tsaki na lokaci ɗaya ana gyara su tare da igiyoyin waya. Ƙimar ƙayyadaddun maɓalli ya kasance ƙasa da nauyin maɓalli da kayan aiki. Babban canji ya yi nisa da wutar lantarki na DC24V. Babban kewayawa yana amfani da AC380V ko AC220V, kuma da’irar sarrafawa tana amfani da DC24V.

Wurin layin ƙasa da ma’aunin layin sifili suna da alama kuma an gyara su bi da bi, kuma an ƙera waya ta ƙasa akan ƙofar majalisar kula da ita.

Hanyar sarrafawa na kowane juzu’i yana da alama akan ƙofar majalisar sarrafawa.

An ƙera ma’aikatar kula da na’urar samun iska (axial flow fan da air inlet grille form convection), kuma tashar musayar iska tana sanye da matattara mai ƙura.

Na’urar haskakawa a cikin ma’aikatar kulawa ba ta da kyau don tabbatar da cewa an kunna kofa, ko kuma an shigar da maɓalli don sarrafa hasken wuta.

Duk ƙayyadaddun ƙayyadaddun layin layi an haɗa su cikin trunking, kuma lambar layin tana alama a sarari. Lambar waya ba ta shuɗe kuma ta dace da zane. An zaɓi diamita na waya yadda ya kamata, kuma ma’aunin zafi da sanyio na infrared yana bincikar cewa babu zafi ko wuce gona da iri na layin.

Shigar da allunan kariyar rufewa da allunan rigakafin bera don fallasa wayoyi masu sauyawa da sandunan tagulla.

A gaban majalisar kulawa, shimfiɗa fakitin roba waɗanda suka dace da buƙatun aminci, kamar darajar rufi da girman.

Don yanayin sarrafa motar: canjin iska + mai lamba + thermal gudun ba da sanda ko kariya ta mota + lamba don tsarin sarrafawa.

Hanyar gyarawa: Abubuwan da aka gyara na lantarki an gyara su a kan ma’ajin sarrafawa tare da ginshiƙan jagora na 35mm.

Hanyar waya: Gyara tare da tasha kuma yi alama lambar waya;

Bangaren PLC: Kayan wutar lantarki na PLC yana da daidaitattun wuraren kariya; an shigar da PLC da ƙarfi kuma yana da iska sosai; an bambanta shigarwa da fitarwa ta layi biyu; akwai fiye da maki 5 I/O don madadin.

Bangaren jujjuyawar: ƙarfin yana da matakin sama da ƙimar ƙarfin injin; layin da ke shigowa yana da tsarin kariya mai ma’ana;

Yi amfani da kwandon wayoyi masu sassauƙa da yawa a cikin majalisar; 220V da DC24V launuka waya sun rabu; wayoyi suna da sarari sarari a cikin kwandon; ana kiyaye hanyar rarraba wutar lantarki tare da roba; ƙarshen waya yana da daidaitaccen lambar waya.

Sashin tashar tashar waya: an shigar da tashar a ƙananan ƙarshen majalisar kulawa, 380V da DC24V an shigar da su daban; an haɗa majalisar rarraba wutar lantarki zuwa kayan aiki na gefe tare da matosai na jirgin sama ko tashoshi na waya.

Trunking na waje misali ne, mai aminci, mai juriya ga matsa lamba, kuma baya lalacewa.

Layin samarwa yana cikin kebul da igiyar waya a cikin rami, kuma an rarraba shi da kyau tare da hanyoyin ruwa da iska.

Alamar layin haɗin haɗin kai na shigarwa da sassa na kayan aiki sun bayyana, ɗorewa, da sauƙin samuwa akan shafin; ba za a rasa su ba saboda maye gurbin sassa;