- 19

- Aug

Izimiso ze-PLC Operating Condition Monitoring System ye-Induction Melting Furnace

Izimiso ze-PLC Operating Condition Monitoring System for I-Induction Melting Furnace

Isistimu yokuqapha isimo sokusebenza se-PLC yesithando somlilo sokungeniswa sihlanganiswa nesikrini esingu-10-intshi esibonisiwe, esinemisebenzi efana nokulawulwa nokulungiseka, ukubonisa okuzenzakalelayo, nenkumbulo ezenzakalelayo.

1. Ikhonsoli yokulawula yangaphandle ye-PLC yesithando somlilo esincibilikayo sokungeniswa ifakwe i-DC voltmeter, i-DC ammeter, i-voltmeter yefrikhwensi ephakathi, imitha yamafrikhwensi aphakathi, imitha yamandla emvamisa emaphakathi, ithuluzi lokubonisa izinga lokushisa, njll. Yonke imingcele yemishini ingaboniswa ngokunembile. Isikrini esithintwayo se-Siemens 10-intshi singasetha kalula ihhavini noma inqubo yokuncibilika, futhi singabonisa izinga lokushisa elincibilikayo namandla wemishini namanye amajika epharamitha ngesikhathi sangempela. I-console iklanywe ngokushintsha kwamandla okulawula, i-intermediate frequency manual kanye ne-othomathikhi, inkinobho yokumisa izimo eziphuthumayo, ukukhanya kwenkomba yamandla, ukukhanya okukhomba imvamisa emaphakathi kanye nesibani esiyisixwayiso sephutha.

2. Ibhodi lokulawula ukunikezwa kwamandla okuvama okumaphakathi liklanywe ngesixhumi esibonakalayo sokulawula izinga lokushisa elivaliwe. Ithuluzi lokulawula izinga lokushisa likhethwa e-Japan Island Electric SR3 ngethuluzi lokulungisa le-PID. Ithemometha yefiber optical ekude ye-infrared ikhethwa ochungechungeni lwethemometha yethusi ekhethekile ye-Optris CT, izinga lokushisa lokulinganisa -40 -900°C. Okokuqala, setha izinga lokushisa lokushisisa nesivinini sokudonsa ensimbini yokulawula izinga lokushisa noma isikrini sokuthinta se-PLC. Ngemva kokuba amandla evuliwe, ithemometha ikala izinga lokushisa lokushisa ngesikhathi sangempela futhi iwuphakele iphinde isebenze ethuluzini lokulawula izinga lokushisa. Ithuluzi lokulawula izinga lokushisa liqhathanisa izinga lokushisa elilinganisiwe nesethi yokushisa yokushisa bese likhipha ukulingisa Isignali ithunyelwa ebhodini eliyinhloko lokulawula imvamisa emaphakathi, futhi ibhodi eliyinhloko lokulawula lilungisa ngokuzenzakalelayo i-trigger angle ye-thyristor ngokwezinga lesiginali, ukuze amandla okukhiphayo okunikezwa kwamandla alungiswe nezinga lesiginali ye-analog, kufezwe injongo yokulawula izinga lokushisa elivaliwe. Lapho ijubane lokuphakela leshubhu yethusi lilungiswa, i-thermometer ithola ukuguquka kwezinga lokushisa kweshubhu yethusi, futhi ikhiphe isignali yamanje ehambisanayo ngokuqhathanisa phakathi kwezinga lokushisa elitholiwe kanye nezinga lokushisa elimisiwe.

Ebhodini lokulawula ifrikhwensi emaphakathi, amandla okukhipha amandla kagesi amaphakathi azolungiswa abe namandla adingekayo ukuze kuzuzwe inhloso yokulawula iluphu evaliwe.

Uchungechunge lwe-CT Optris ithemometha ekhethekile yokulinganisa ithusi

3. I-intermediate frequency switch ye-console yokulawula yangaphandle iklanywe ngama-knobs okusebenza ngesandla kanye ne-othomathikhi. Lapho imodi ezenzakalelayo ikhethiwe, okokusebenza kusebenzisa isistimu yokulawula izinga lokushisa elivaliwe, futhi amandla emishini alungisa ngokuzenzakalelayo amandla okukhiphayo ngokuvumelana nezinga lokushisa elincibilikayo elimisiwe. Ibhodi lokulawula ukunikezwa kwamandla okuvama okumaphakathi liklanywe ngesixhumi esibonakalayo sokulawula izinga lokushisa elivaliwe. Ithuluzi lokulawula izinga lokushisa likhetha i-Shimadden SR3 enensimbi yokulungisa ye-PID, futhi ithemometha ye-fiber optic ekude kakhulu ikhetha uchungechunge olukhethekile lwe-German Optris CT thermometer, futhi izinga lokushisa lingu-385-1600℃. Okokuqala setha izinga lokushisa elincibilikayo ensimbini yokulawula izinga lokushisa noma esikrinini sokuthinta se-PLC. Ngemuva kokuthi ukunikezwa kwamandla okuvama okumaphakathi kuqalisiwe, ithemometha ikala izinga lokushisa eliqinile ngesikhathi sangempela bese iwaphakela iwubuyisele ethuluzini lokulawula izinga lokushisa. Ithuluzi lokulawula izinga lokushisa liqhathanisa izinga lokushisa elilinganisiwe nezinga lokushisa elibekiwe bese likhipha isignali ye-analog ebhodini lokulawula eliyinhloko le-IF, ibhodi eliyinhloko lokulawula lilungisa ngokuzenzakalelayo i-trigger angle ye-thyristor ngokwezinga lesiginali, ukuze amandla okukhiphayo. kokunikezwa kwamandla kungalungiswa ngezinga lesiginali ye-analog. Uma umsebenzisi ekhetha imodi yokusebenza mathupha, idivayisi incibilika ngamandla amakhulu okukhiphayo.

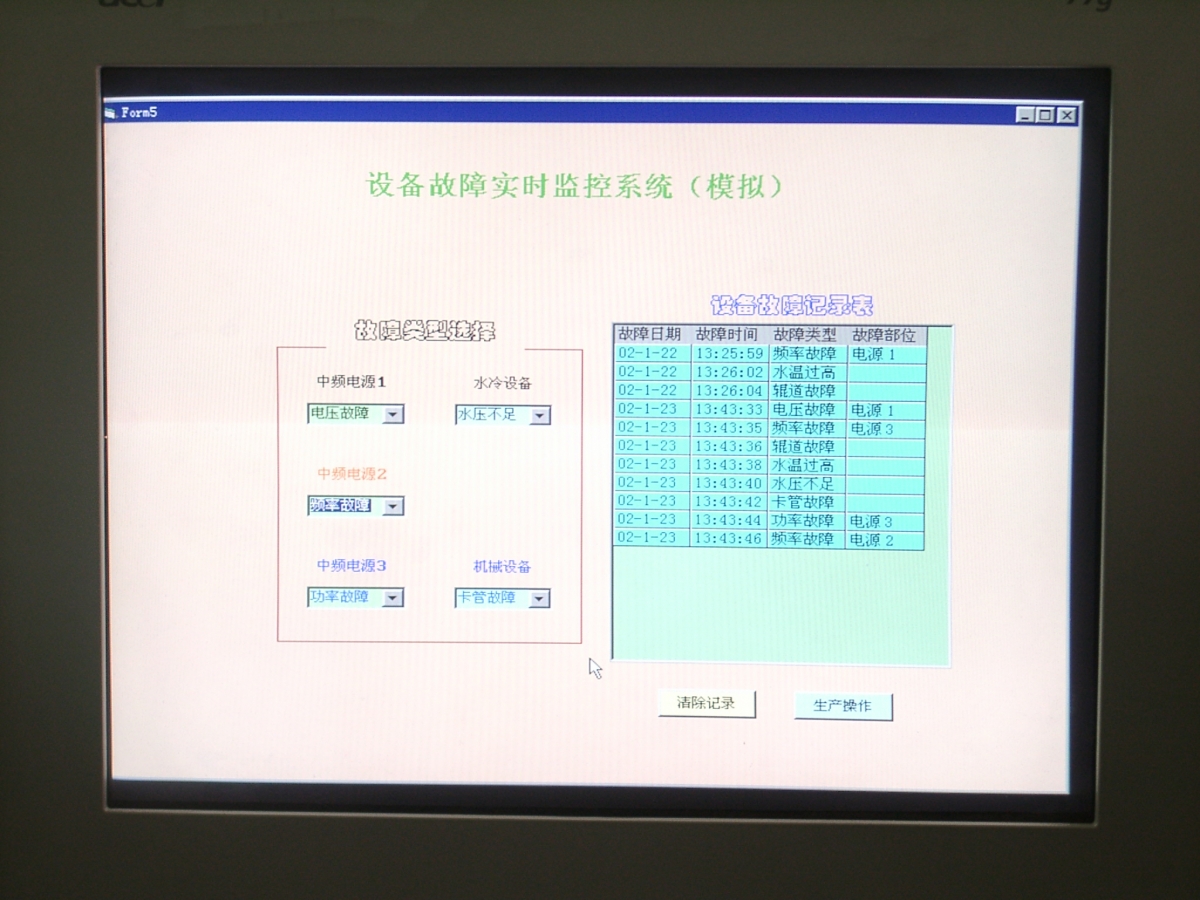

4. Ngaphezu kokubonisa isimo sokusebenza semishini, isikrini sokuthinta singaphinda siqaphe ukwehluleka kwemishini futhi sinikeze amathiphu okulungisa nolunye ulwazi. Umhlahlandlela wokusebenza uhambisana nezinqubo zokusebenza zemishini, izenzakalo ezivamile zokuhluleka kanye nezindlela zokwelashwa.

UMA uhlelo lokusebenza lokuqapha isimo sezinto zokusebenza ze-PLC lungaba nale misebenzi elandelayo:

I-1) Qedela imisebenzi yokulawula ukuncibilika, ukuxilongwa kwephutha okuzenzakalelayo, ukufakwa kolwelwesi okuzenzakalelayo neminye imisebenzi. 2) 2) Umsebenzi ophelele wokulawula inqubo yokuncibilika nokuqapha okuphelele, i-alamu kanye nomsebenzi wokuzihlola ngephutha. 3) 3) Gcwalisa isistimu ye-alamu yomsindo nokukhanya, ezothusa izimo ezilandelayo:

Ikhabhinethi yokuguqula imvamisa ivuliwe;

I-capacitor ilimele;

Izinga lokushisa lamanzi okupholisa kumjikelezo ngamunye wokunikezwa kwamandla liphezulu kakhulu;

Umfutho wamanzi okupholisa amandla uphansi kakhulu;

Izinga lokushisa lamanzi okupholisa esithandweni liphezulu kakhulu;

Ukucindezela kwamanzi okupholisa esithandweni kuphansi kakhulu;

Iswishi yokukhetha isithando somlilo/yokuzihlukanisa ayilungile;

Ingxenye yokulungisa kabusha ye-variable frequency power supply ayinakho okukhiphayo kwe-DC;

I-alamu yokutholwa kwesithando somlilo / evuzayo.

Lawula ikhabethe nokufakwa kokusabalalisa amandla kanye nobuchwepheshe bezintambo:

Iswishi eyinhloko: Isistimu yezintambo eziyisishiyagalombili engenayo enezintambo eziyisishiyagalombili, okungukuthi, ukunikezwa kwamandla kwezigaba eziyisithupha, intambo ephansi yesigaba esisodwa, nocingo olungathathi hlangothi lwesigaba esisodwa kugxilwe ngamalugi ezintambo. Umthamo wokucaciswa kweswishi ungaphansi komthwalo we-sub-switch kanye nemishini. Iswishi eyinhloko ikude nogesi we-DC24V. Isekethe enkulu isebenzisa i-AC380V noma i-AC220V, futhi isifunda sokulawula sisebenzisa i-DC24V.

Ibha yomugqa ophansi kanye nebha yomugqa onguziro imakwe futhi ilungiswe ngokulandelana, futhi ucingo oluwela phansi lwakhiwe emnyango wekhabhinethi yokulawula.

Indlela yokulawula ye-sub-switch ngayinye imakwe emnyango wekhabhinethi yokulawula.

Ikhabhinethi yokulawula iklanywe ngedivayisi yokungenisa umoya (i-axial flow fan kanye ne-air inlet grille form convection), futhi imbobo yokushintshanisa umoya ifakwe isihlungi sothuli.

Idivayisi yokukhanyisa kukhabhinethi yokulawula iphelele ukuze kuqinisekiswe ukuthi umnyango uvuliwe, noma umshini wokukhanyisa ufakiwe ukulawula ukukhanya.

Zonke izichasiselo zomzila wolayini zifakiwe ku-trunking, futhi inombolo yolayini imakwe ngokucacile. Inombolo yocingo ayifihli futhi ihambisana nomdwebo. I-diameter yocingo ikhethwa ngokufanelekile, futhi i-thermometer ye-infrared ihlola ukuthi akukho ukushisa ngokweqile noma ukulayishwa ngokweqile kwemigqa.

Faka amabhodi okuvikela amagundane kanye namabhodi angangeni kumagundane ukuze uthole izintambo eziveziwe zokushintsha kanye nezinsimbi zethusi.

Phambi kwekhabhinethi yokulawula, beka amaphedi enjoloba ahlangabezana nezidingo zokuphepha, njengebanga lokufakelwa kanye nosayizi.

Ngemodi yokulawula imoto: switch yomoya + i-contactor + i-thermal relay noma isivikelo semoto + isixhumi sohlelo lokulawula.

Indlela yokulungisa: Izingxenye zikagesi zigxilile ekhabetheni lokulawula elinama-rail angu-35mm ajwayelekile omhlahlandlela.

Indlela yokufaka izintambo: Lungisa ngetheminali bese umaka inombolo yocingo;

Ingxenye ye-PLC: Amandla kagesi we-PLC anezindawo zokuvikela ezihambisanayo; i-PLC ifakwe ngokuqinile futhi inomoya omuhle; okokufaka nokuphumayo kuhlukaniswa ngemigqa emibili; kunamaphuzu we-I/O angaphezu kwama-5 wokwenza ikhophi yasenqolobaneni.

Ingxenye ye-inverter: umthamo uyizinga elilodwa eliphakeme kunamandla alinganiselwe emoto; ulayini ongenayo unohlelo lokuvikela oluphusile;

Sebenzisa i-multi-core flexible wiring trough ekhabetheni; Imibala yocingo engu-220V kanye ne-DC24V ihlukaniswe; izintambo zinendawo engenalutho emkhombeni; i-outlet yolayini wokusabalalisa amandla ivikelwe ngerabha; ukuphela kwentambo kunenombolo yocingo evamile.

Ingxenye yokugcina izintambo: i-terminal ifakwe ekugcineni kwekhabhinethi yokulawula, i-380V ne-DC24V ifakwe ngokuhlukana; iKhabhinethi yokusabalalisa amandla ixhunywe kumishini ye-peripheral ngamapulaki endiza noma amatheminali ezintambo.

I-trunking yangaphandle ijwayelekile, iphephile, imelana nengcindezi yokunyathela, futhi ayigugi.

Ulayini wokukhiqiza usemgqeni wekhebula kanye nentambo emseleni, futhi usatshalaliswa ngokunengqondo emanzini kanye nezindlela zomoya.

Amamaki ezinombolo zomugqa wokuxhuma wezingxenye zokufakwayo neziphumayo zemishini acacile, aqinile, futhi kulula ukuwathola esizeni; ngeke balahleke ngenxa yokushintshwa kwezingxenye;